Your Global One-Stop Expert for Industrial Parts Production and Solutions

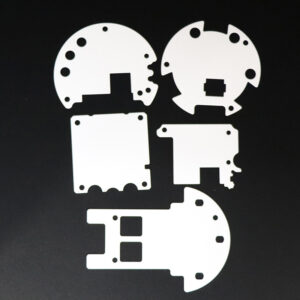

- Precision Parts Full Industry Chain Layout (Motors/Micro stamping parts/Structural ceramic parts)

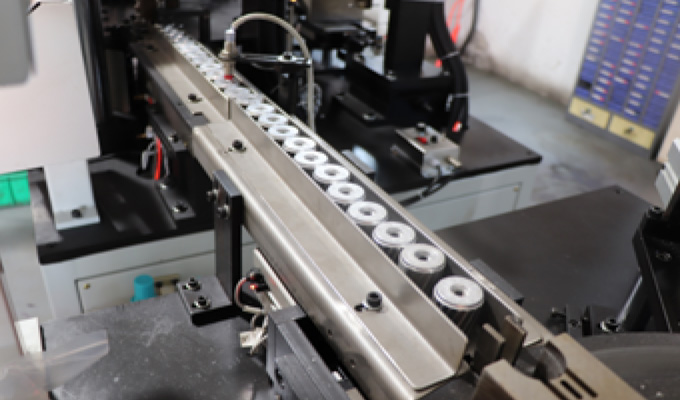

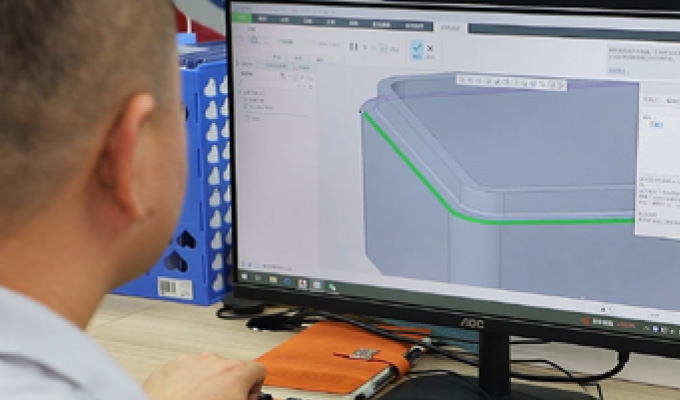

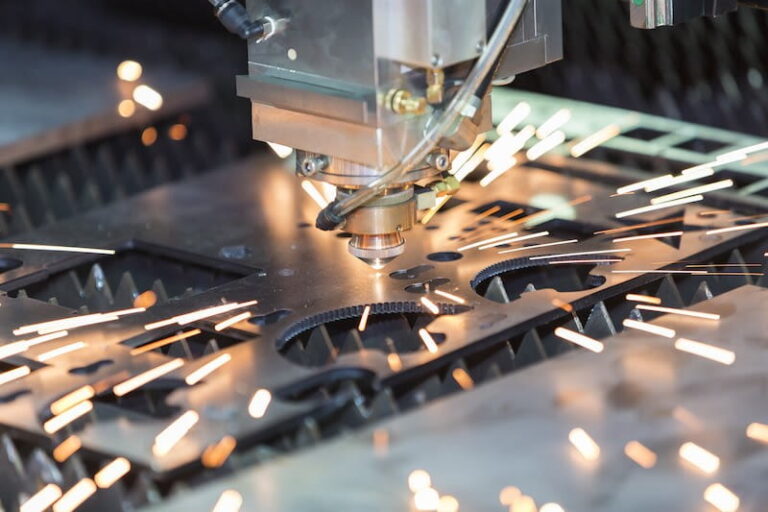

- High-Efficiency Digital Automated Production Equipment

- Deep Customized Solutions

- Aviation-Grade Technical Standards

Cooperated with fortune 500 companies for more than 17 years

50+ utility model patents,100+ experienced engineers

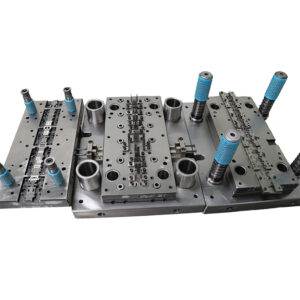

In-house mold manufacturing and advanced technology offer better pricing,reducing material waste by 35-45%

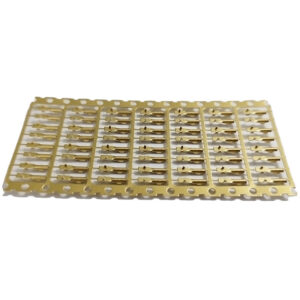

Over 1 billion pieces/year, progressive die & transfer die stamping,high efficiency for mass production

Industrial Parts Production

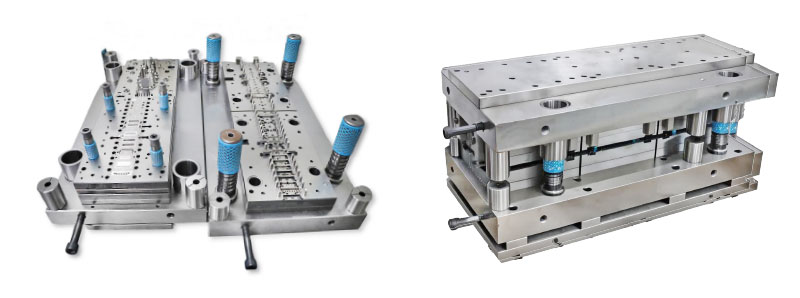

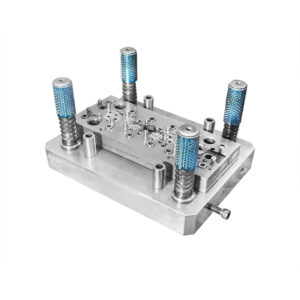

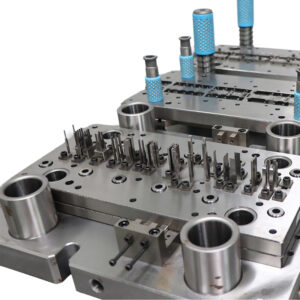

Precision Hardware & Stamping Dies Full-Chain Intelligent Manufacturing Capabilities

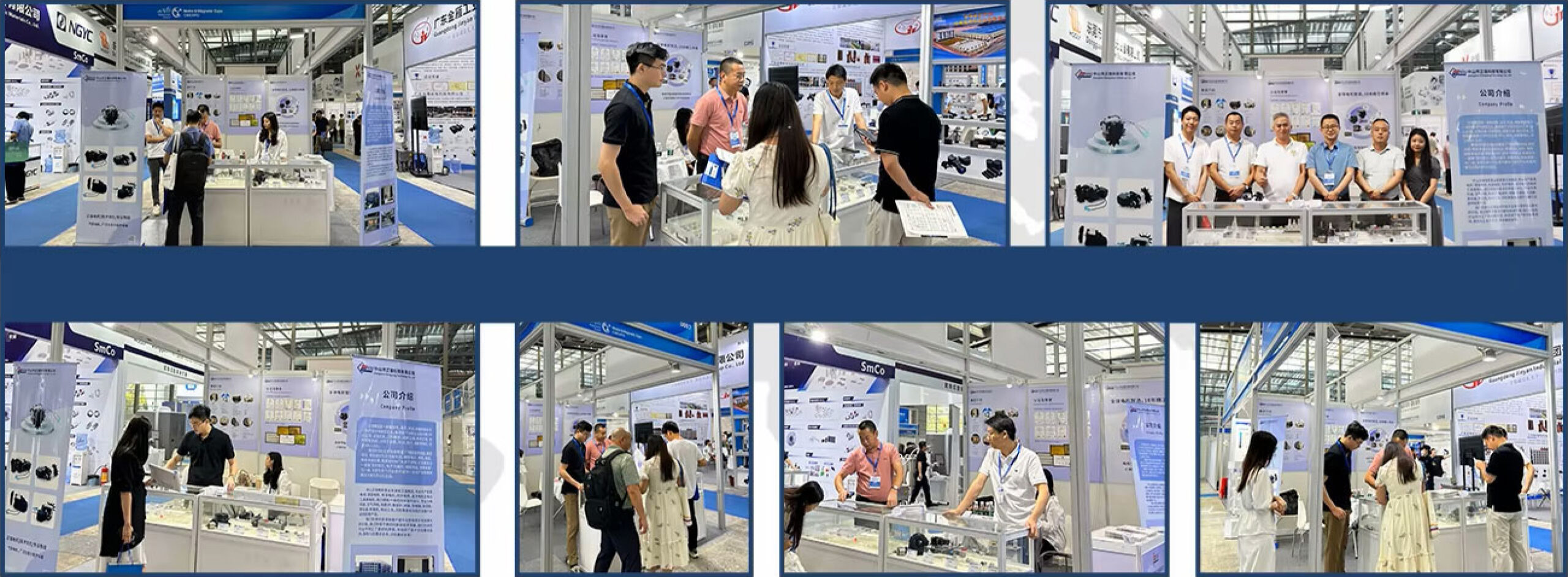

Zhengqiang is driven by the dual engines of "technology + production capacity" to provide precise and efficient solutions to global industrial customers.

● Extension Mold Technology:

Wide range thickness of workpieces from 6 mm to 0.1mm.

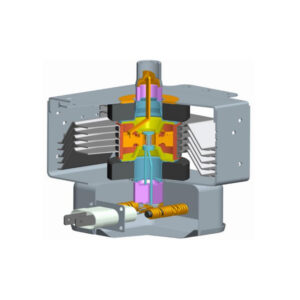

● Micro Deep Drawing Technology:

Max 7cm depth, replacing Japanese and Korean turning processes.

● Micro-Diameter Rolling:

Industry-leading 3.18mm diameter for diverse applications.

Provide 5000+ pcs/year Precision Molds Worldwide

- Free DFM analysis, optimized design and cost reduction of 20%

- 100+ mold expert team, 24-hour quick response

- 500+ equipment clusters, first version of mold delivered in 7 days

Requirement & DFM

Design & Prototyping

Mold Development

Testing & Validation

Fine-Tuning & Approval

Delivery & After-Sales

Precision Hardware

Precision Hardware

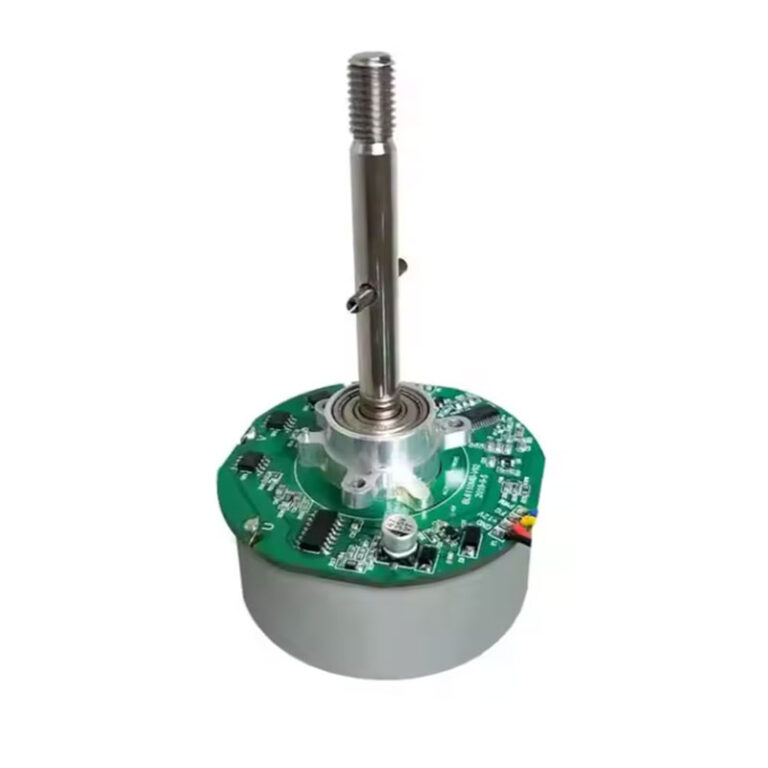

Motor

Motor

Ceramics

Ceramics

About

Zhengqiang Group

- 6 Subsidiaries

- 17 Years Of Deep Cultivation In Related Industry

- 50+ Patented Technologies

- Annual Production Capacity Of 24 Million Motors

- Delivery Capacity Of 1 Billion Hardware Components

Industrial Parts Production | Precision Components & Solutions

Industrial parts production with full-chain solutions: precision motors, ceramics, stamping, customization, aerospace standards.

Quality

CERTIFICATIONS

The company has a number of patent certificates and strictly implements international quality control standards in production to ensure product quality. It has passed lSO 9001, lSO4001, 45001, NPA, IATF16949, IPMZ certifications, etc.

INDUSTRY APPLICATIONS

Our products are used in a variety of applications,

including home appliances, consumer electronics, automobile manufacturing, new energy, photovoltaic energy storage, medical health, communication equipment, aerospace applications, etc.

We also provide precision hardware, stamping dies, motors, and ceramic manufacturing solutions for various industries.

Global Industrial Parts Production Solutions

Why Choose Zhengqiang?

Technical Support

Patented technology defines a new height in the industry, the world's 3.18mm micro-diameter rolling technology, deep and long extension process replaces Japanese and Korean turning, and the cost is reduced by 30%

Quality Support

AI full inspection + manual double review, defect rate ≤ 0.12%, 0.01mm precision control, exceeding ISO9001 standard by 30%.

Production Capacity Support

6 major intelligent manufacturing bases, 46,489 square meters of production area, 1 billion-level production capacity, to meet the needs of trial production and large orders.

Price Support

Self-developed intelligent production line efficiency increased by 500%, labor costs saved by 50%; the whole industry chain coordinated to reduce costs, mold development cycle shortened by 70%, price competitiveness industry TOP3.

Delivery Support

99.6% order on-time delivery rate, support "small batch trial production → mass production within 1 week" seamless switching, delayed compensation clause.

Full Industry Chain Support

Mold/precision hardware/motor/capacitor/ceramic/ surface treatment multi-division collaboration to provide you with a one-stop solution.

More About Us

GLOBAL EXHIBITIONS &CUSTOMER FACTORY INSPECTION

Latest Information

BLOG

Comprehensive Guide to Metal Stamping in Hardware Manufacturing | Zhongshan ZhengQiang Technology

Comprehensive Guide to Metal Stamping in Hardware Manufacturing | Zhongshan ZhengQiang Technology The Critical Role of Metal Stamping in Hardware

Sheet Metal Fabrication Guide | ZhengQiang Professional Cold Forming Services — Precision Manufacturing & Best Practices

Advanced Guide to Sheet Metal Fabrication: Cold Forming for Modern Industrial Applications Sheet metal fabrication plays a critical role in

What is Appliances Precision Steel Stamping Parts? A Complete Guide to 2025

Author | Zhengqiang Industry Insights Team Updated | December 2025 Introduction: In today’s fast-paced manufacturing world, precision is key. Whether you’re

What Is 120V Motor Price? A Complete Guide to 2025

Author | Zhengqiang Industry Insights Team Updated | December 2025 Introduction: Understanding 120V Motor Price in a Changing Market In 2025,