Features:

1.High hardness and wear resistance

2.High temperature resistance and corrosion resistance

3.Similar liner expansion coefficient to steel, providing better thermal compatibility with steel.

Application

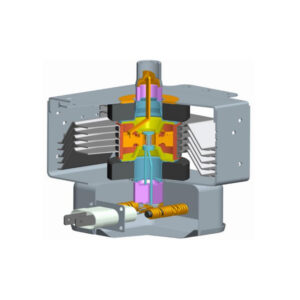

New energy vehicle water pump, enhancing the lifespan of the water pump rotor

Products details

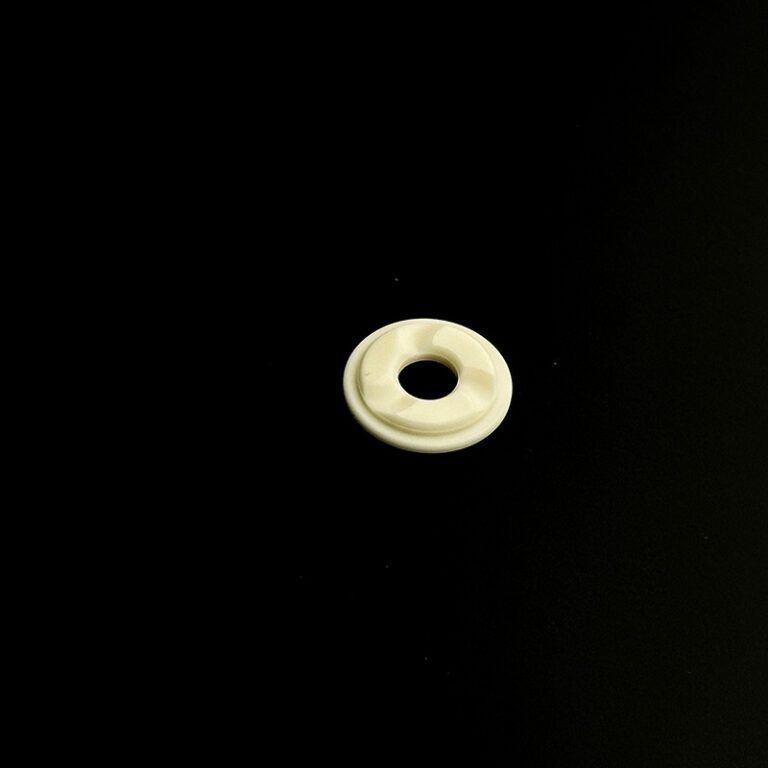

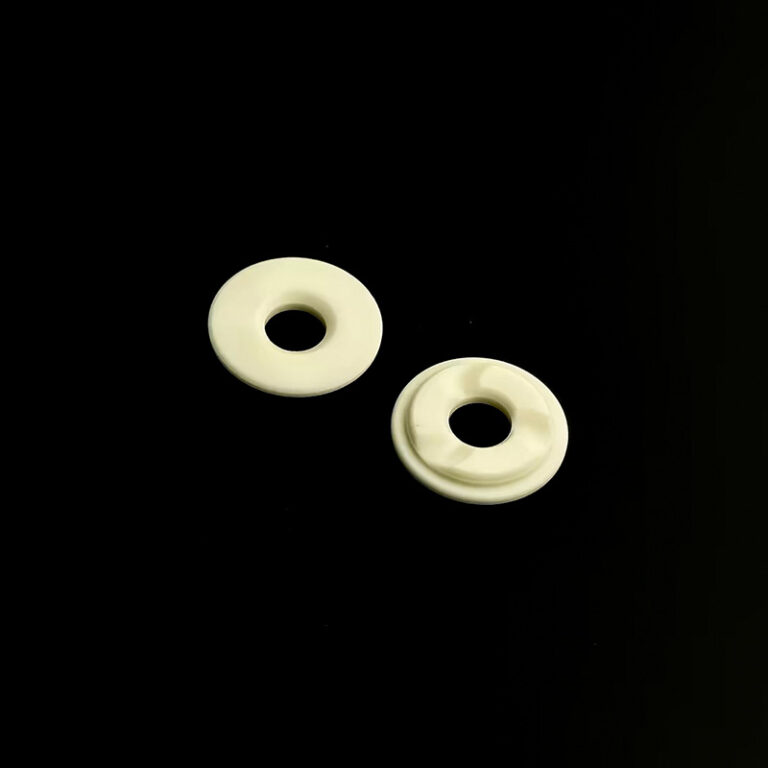

99% Alumina Ceramic for New Energy Vehicle Water Pump – Durable & Precise

Zhengqiang provides 99% alumina ceramic components specifically engineered for new energy vehicle (NEV) water pump systems. These ceramic rings are made with high-purity alumina, delivering exceptional wear resistance, thermal stability, and dimensional precision. Their coefficient of thermal expansion is similar to steel, making them ideal for use alongside metal components in hybrid and electric vehicle systems.

Specification

Why Choose 99% Alumina Ceramic for EV Water Pump Applications?

Our alumina ceramic for new energy vehicle water pumps enhances pump durability by resisting abrasion, high temperatures, and chemical corrosion. Compared to traditional metal or plastic parts, alumina maintains its strength under extreme thermal cycling, which helps prolong the rotor’s lifespan. These parts are widely used by Tier 1 and Tier 2 suppliers in the NEV supply chain.

Learn more about alumina ceramics on Wikipedia – a high-performance engineering ceramic used across automotive and energy industries.(外链)

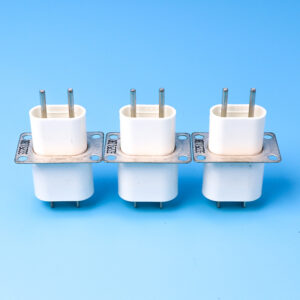

Custom Ceramic Parts from a Trusted B2B Manufacturer

As a B2B factory, Zhengqiang supports custom precision ceramic machining for various industries. Whether you require small-batch prototyping or high-volume production, our CNC-controlled manufacturing and ISO-certified QC ensure product consistency.

👉 Interested in other automotive ceramic components? Check our engineering ceramics portfolio for more solutions.