Our EV Energy Storage Connector leverages copper cold extrusion manufacturing to replace traditional machining methods. This innovation reduces material waste by up to 35% and slashes production costs by 20%, while enhancing dimensional precision for seamless integration into battery packs and energy storage units.

2. World-Class Certification & Reliability

Rigorously tested to exceed IEC 62196 and UL 1977 standards, our connectors undergo 10,000+ cycle durability tests, high-voltage insulation checks, and extreme temperature (-40°C to 150°C) validation. Proven to meet the demands of global automotive and energy giants.

3. Proven Mass Production Stability

With 3+ years of uninterrupted large-scale production, we deliver 99.8% defect-free batches through automated quality control systems. Our lean manufacturing ensures consistent supply for OEMs, supporting just-in-time delivery for high-volume EV and ESS projects.

4. Universal Compatibility Across Platforms

Designed for versatility, our connectors adapt to diverse voltage ranges (300V–1500V) and configurations. Ideal for:

EV battery module interconnects

Energy storage cabinet busbar links

Fast-charging station power transmission

Hybrid/electric commercial vehicle systems

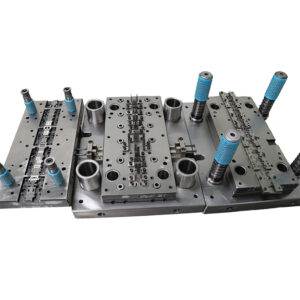

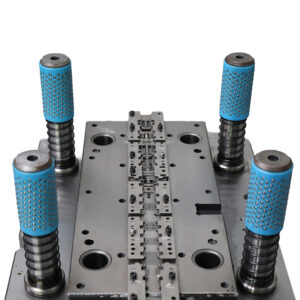

Products details

Eco Extrude EV Connector Technology

Eco Extrude EV Connector reduces material waste by 35% via copper cold extrusion. Exceeds IEC 62196/UL 1977 standards for battery packs & energy storage systems. 99.8% defect-free

Revolutionary Cold Extrusion Advantages

Precision Manufacturing

-

35% less material waste vs machining

-

20% lower production costs

-

±0.1mm dimensional accuracy

Performance Validation

| Test | Standard |

|---|---|

| Durability | 10,000+ cycles |

| Temperature | -40°C to 150°C |

| IEC 62196 PDF |

Certified Reliability for EV/ESS

Global Compliance

✔ UL 1977 (North America)

✔ IEC 62196 (International)

✔ GB/T 20234 (China)

Quality Assurance

-

99.8% defect-free rate

-

Automated optical inspection

Universal Platform Compatibility

Applications

-

EV Battery Packs: 300V-1500V systems

-

Energy Storage: Cabinet busbar links

Custom Solutions

-

Tin/Nickel plating options

-

Adjustable lengths/angles

Application :

New Energy Vehicles, Energy Storage Systems

Eco Extrude EV Connector Advantages:

Energy Efficiency: Ultra-low resistance (<0.15μΩ) minimizes thermal loss.

Corrosion Resistance: Tin-plated or nickel-coated options for harsh environments.

Scalability: Customizable lengths, angles, and terminal sizes.

Sustainability: Fully recyclable materials align with circular economy goals.

Why Choose Us?

Certified Excellence: Compliant with IATF 16949 and ISO 14001 standards.

R&D Agility: 30-day rapid prototyping for custom designs.

Global Support: Warehouses in EU, Asia, and North America ensure prompt logistics.