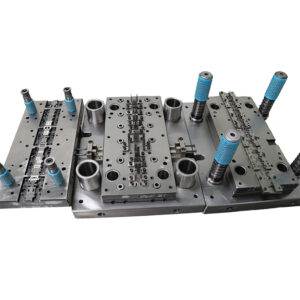

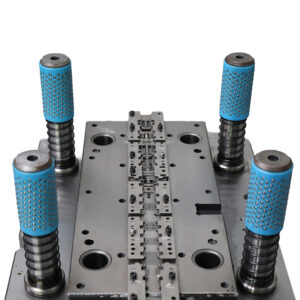

Our VVT Phaser Cover Plate is manufactured using general punching machines instead of high-precision stamping equipment. This innovative approach significantly reduces energy consumption during production while maintaining stringent quality standards. By optimizing the manufacturing process, we minimize operational costs, delivering a cost-effective solution without compromising performance.

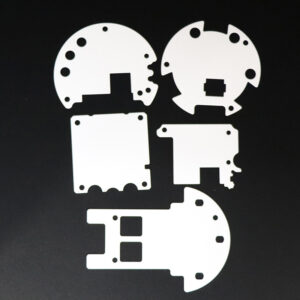

2. Single-Stamp Complex Structure Formation

All intricate design features, including flanged holes and multi-dimensional contours, are achieved through a single precision stamping process. This eliminates the need for secondary machining operations, streamlining production timelines and reducing material waste. The result is a structurally robust component with consistent dimensional accuracy, ready for immediate assembly.

3. OEM-Compliant Quality & Extensive Market Adaptability

Engineered to meet or exceed OEM specifications, our VVT Phaser Cover Plate benefits from over a decade of proven mass production expertise. With rigorous quality control systems, we ensure long-term durability and reliable performance under extreme engine conditions. Our portfolio includes 20+ product variants designed to accommodate diverse engine configurations, serving the needs of global engine manufacturers across automotive, industrial, and commercial vehicle sectors.

Products details

EcoStamp VVT Cover Technology

Energy & Cost Efficient Production

Sustainable Manufacturing

-

30% lower energy use vs high-precision stamping

-

General punching machines reduce carbon footprint

Cost Optimization

| Method | Cost Reduction |

|---|---|

| Material Waste | 15% less |

| Secondary Machining | Eliminated |

| SAE Energy Efficiency Standards |

Single-Stamp Complex Structures

Precision Engineering

✔ Flanged holes formed in one operation

✔ Multi-dimensional contours with ±0.1mm tolerance

✔ 20+ design variants available

Quality Assurance

-

100% dimensional checks with CMM

OEM EcoStamp VVT Cover Compliance & Global Applications

Automotive Solutions

-

Passenger cars & commercial vehicles

-

Hybrid/electric vehicle engines

EcoStamp VVT Cover Industrial Adaptability

-

Agricultural machinery

-

Marine engines

EcoStamp VVT Cover Application :

VVT Engine

Our Advantages:

Sustainability Focus: Reduced carbon footprint through energy-conscious manufacturing.

Precision Engineering: Zero post-stamping machining guarantees part consistency.

Scalable Supply: Mature production infrastructure supports large-volume orders.

Cross-Platform Compatibility: Comprehensive product range simplifies OEM integration.

Ideal for modern VVT engines, our cover plate enhances timing system efficiency while delivering unmatched cost-performance value. Contact us to explore tailored solutions for your engine production requirements.