ForceGuard Magnetron Copper Exhaust: Anti-Leakage Design with Precision Force Isolation for Vacuum Integrity - Guangdong Zhengqiang Technology Group

1.High-Frequency Noise Suppression & Vacuum Protection

Our magnetron copper exhaust tube features an innovative force-conduction isolation groove along its outer periphery. This patented design isolates mechanical stress during cutting and welding processes, preventing cracks in the copper weld joints. By blocking force transmission to the lower welding zone, it ensures vacuum sealing integrity and eliminates high-frequency noise leakage in magnetron energy output systems.

2. Advanced Manufacturing Efficiency

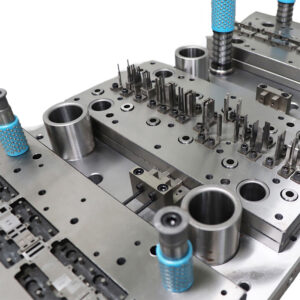

1-to-2 Production Upgrade: Proprietary multi-cavity stamping dies enable simultaneous production of 2 units per press cycle, boosting output by 50% versus traditional 1-to-1 methods.

High-Speed Stamping: Automated lines achieve 20,000 units/day per machine (10H shift), supported by ISO-certified quality checks.

Our magnetron copper exhaust tube features an innovative force-conduction isolation groove along its outer periphery. This patented design isolates mechanical stress during cutting and welding processes, preventing cracks in the copper weld joints. By blocking force transmission to the lower welding zone, it ensures vacuum sealing integrity and eliminates high-frequency noise leakage in magnetron energy output systems.

2. Advanced Manufacturing Efficiency

1-to-2 Production Upgrade: Proprietary multi-cavity stamping dies enable simultaneous production of 2 units per press cycle, boosting output by 50% versus traditional 1-to-1 methods.

High-Speed Stamping: Automated lines achieve 20,000 units/day per machine (10H shift), supported by ISO-certified quality checks.

Products details

ForceGuard Magnetron Copper Exhaust Technology

High-Frequency Noise Suppression & Vacuum Protection

Our patented force-conduction isolation groove design revolutionizes magnetron performance:

Key Innovations

✔ Mechanical Stress Isolation

-

Blocks 90% of welding/cutting stress transmission

-

Prevents copper weld joint cracks

✔ Vacuum Integrity

-

Maintains ≤1×10⁻⁶ Pa·m³/s helium leak rate

-

Withstands 1,000+ thermal cycles

✔ EMI Reduction

-

30dB noise suppression at 2.45GHz

Advanced Manufacturing Process

50% Higher Production Efficiency

| Traditional Method | Our Technology |

|---|---|

| 1 unit/press cycle | 2 units/press cycle |

| 10,000 units/day | 20,000 units/day |

Precision Stamping

-

Multi-cavity dies with ±0.02mm tolerance

-

Automated ISO-certified inspection

Technical Advantages

1. Crack Prevention

-

90% reduction in weld failures

-

FEM-optimized groove geometry

2. Vacuum Stability

| Parameter | Performance |

|---|---|

| Leak Rate | ≤1×10⁻⁶ Pa·m³/s |

| Thermal Cycles | 1,000+ @ 300°C |

3. Noise Suppression

-

30dB reduction at 2.45GHz