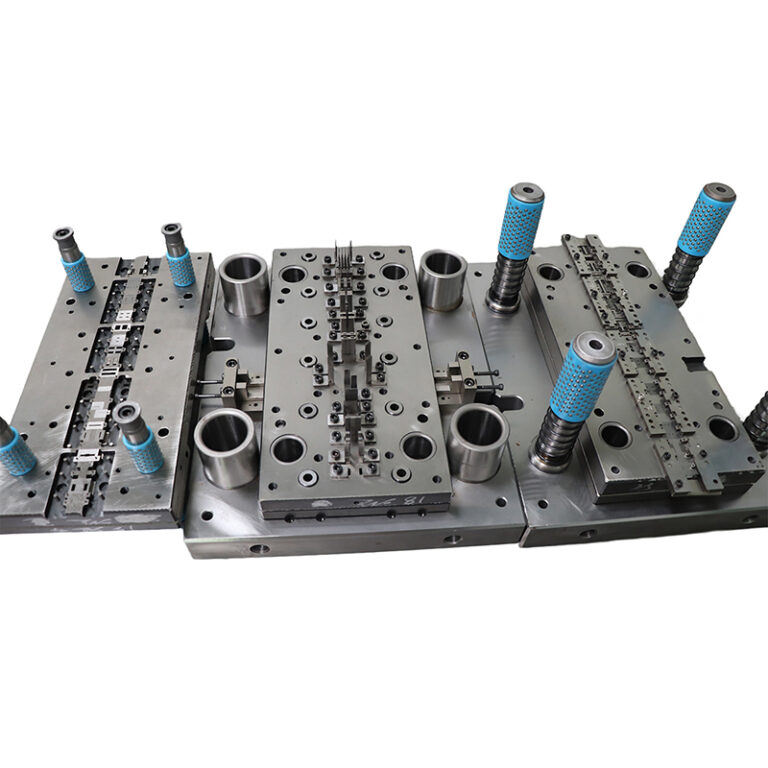

Specializing in cold extrusion processes, these dies shape high-strength materials (e.g., SPCC steel) into complex geometries without heat treatment. The process ensures enhanced mechanical properties (e.g., tensile strength ≥450MPa) and burr-free edges through precision tool alignment.

Products details

Cold Heading Dies for High-Strength Components

What Are Cold Heading Dies?

Cold heading dies are specialized tools used in cold forging processes to form metal wires into high-strength fasteners (bolts, screws, nuts) without heating. This process enhances material strength and durability while maintaining tight tolerances (±0.02mm).

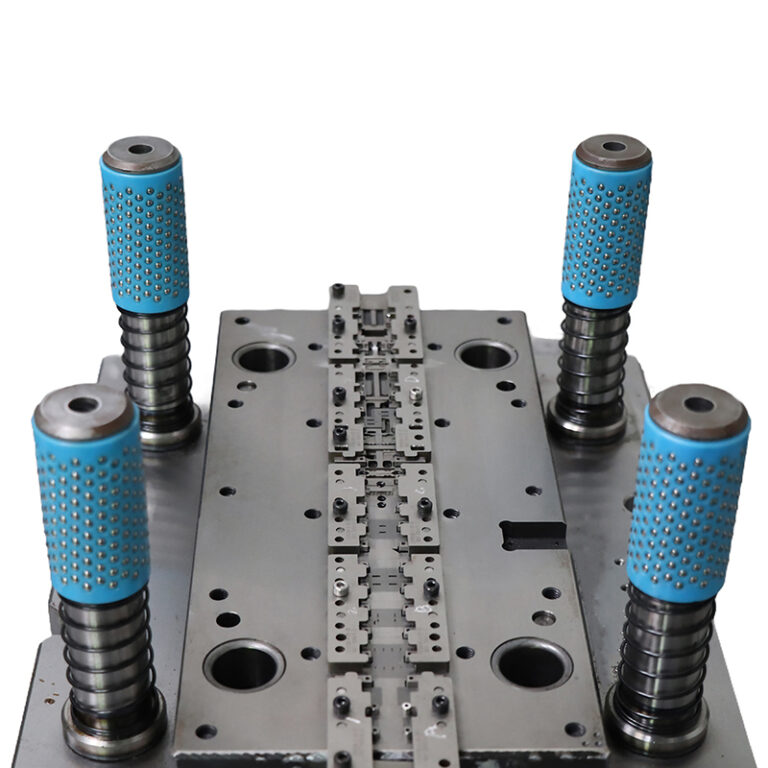

Key Features

✔ High-Speed Production – Capable of 50,000+ units/day

✔ Material Versatility – Works with stainless steel, alloy steel, titanium

✔ Precision Tolerances – ±0.02mm for critical dimensions

✔ Extended Die Life – Made from premium tool steels (e.g., SKD11, SLD-Magic)

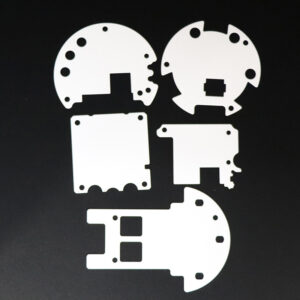

Applications of Cold Heading Dies

1. Automotive Fasteners

-

Engine bolts, wheel studs, suspension components

2. Aerospace Components

-

Titanium fasteners, high-strength rivets

3. Construction & Industrial

-

Structural bolts, anchor rods, heavy-duty nuts

Why Choose Our Cold Heading Dies?

1. Superior Material Strength

-

Increases tensile strength by 20-30% vs traditional machining

-

Grain flow optimization for enhanced durability

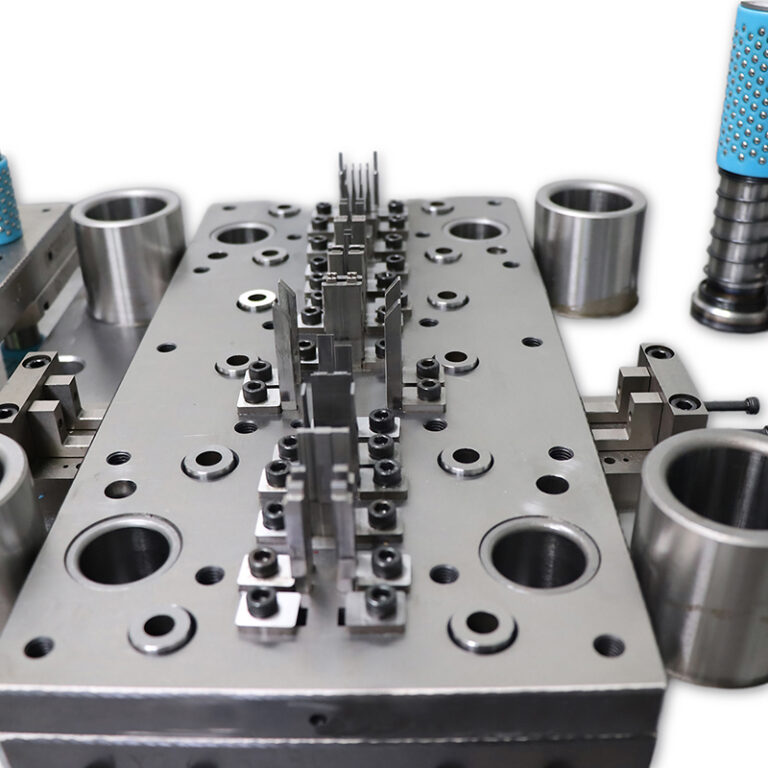

2. Precision Engineering

-

Multi-station dies for complex geometries

-

Computer-simulated stress analysis for optimal performance

3. Cost Efficiency

-

Near-zero material waste (98%+ material utilization)

-

Automated production reduces labor costs

Learn more about Zhengqiang’s strength

Technical Specifications

| Feature | Specification |

|---|---|

| Material Compatibility | Stainless steel, alloy steel, titanium |

| Diameter Range | 2mm-30mm |

| Tolerance | ±0.02mm (critical dimensions) |

| Production Speed | Up to 300 parts/minute |

| Die Life | 500,000+ cycles (standard materials) |