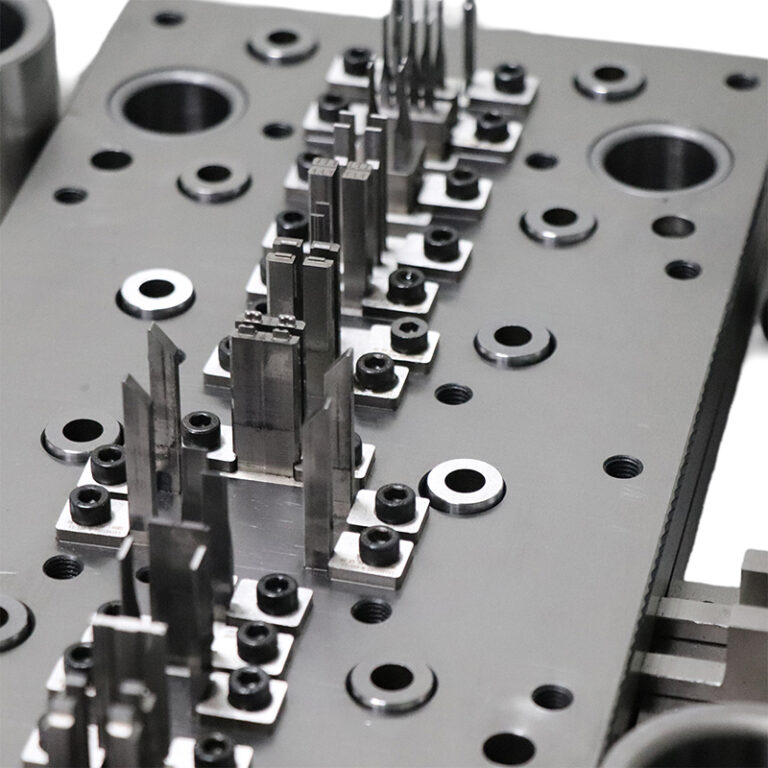

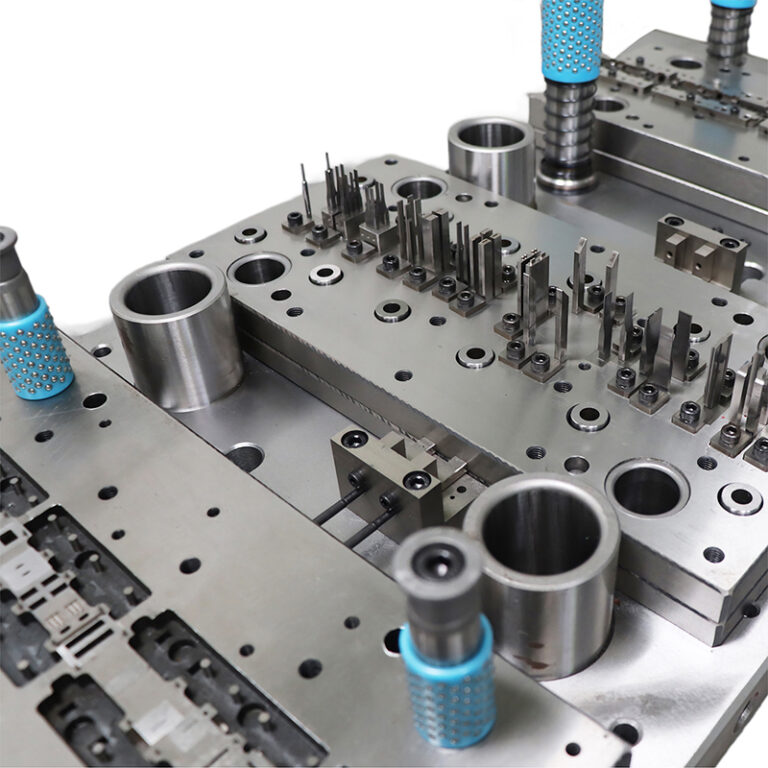

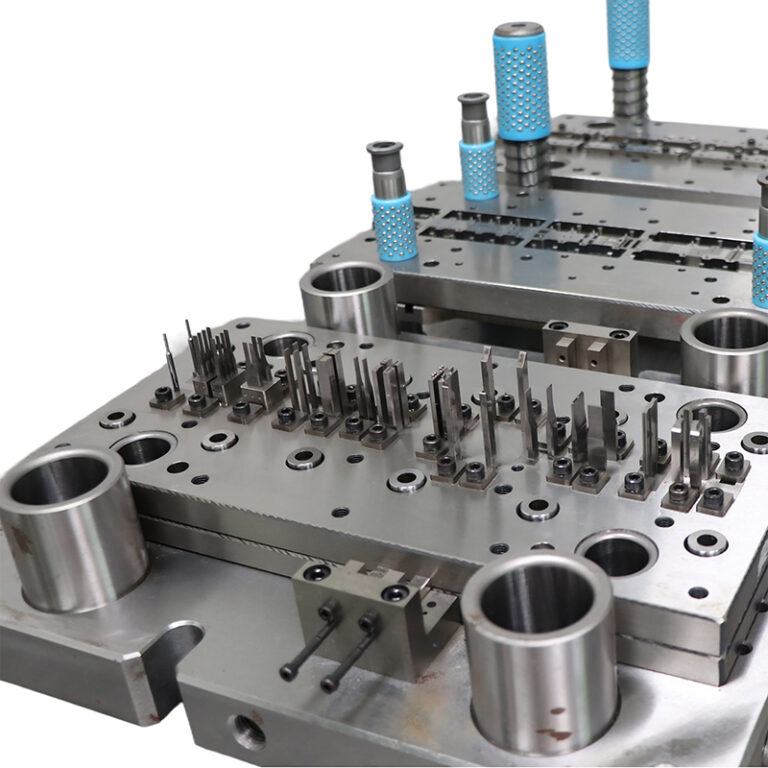

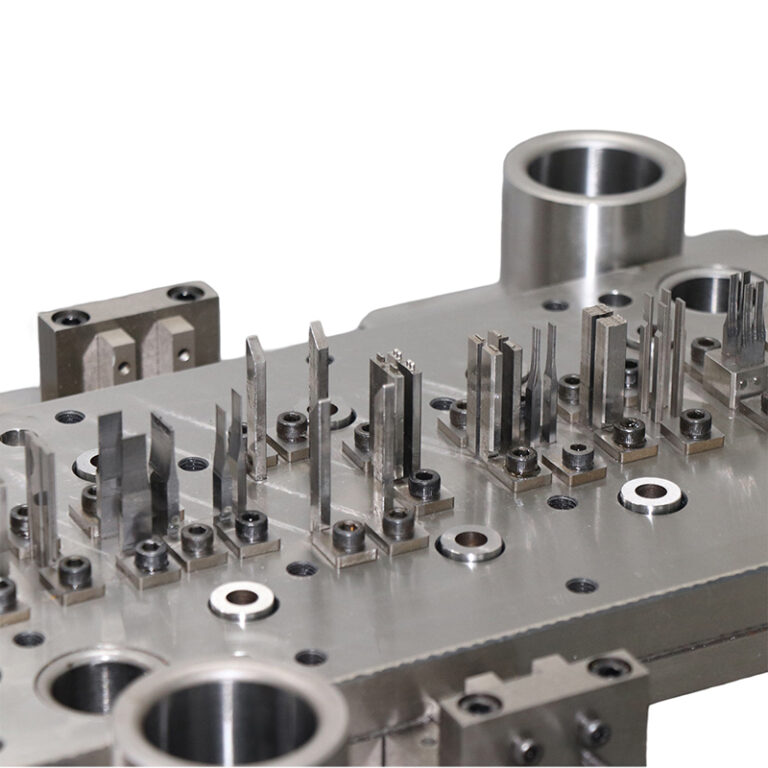

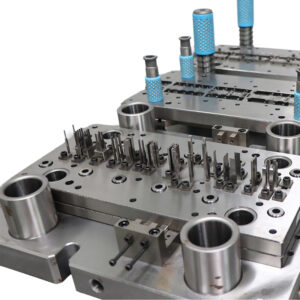

Engineered for multi-stage deep drawing (e.g., primary, secondary, and fine drawing), these dies process materials like SUS304 stainless steel (0.4mm thickness) into seamless cylindrical or box-shaped components. The four-side strip feeding design ensures consistent material flow, critical for maintaining wall thickness uniformity.

Products details

What Are Deep-Draw Stamping Dies?

Deep-draw stamping dies are specialized tools used to form sheet metal into deep, seamless shapes (e.g., cylinders, boxes, and complex geometries) through multi-stage drawing processes. These dies are essential for industries requiring high precision (±0.05mm tolerance) and uniform wall thickness.

Key Features

✔ Multi-Stage Drawing – Primary, secondary, and fine drawing for deep, intricate shapes.

✔ Four-Side Strip Feeding – Ensures smooth material flow and prevents wrinkling.

✔ Material Compatibility – Works with SUS304 stainless steel (0.4mm thickness), aluminum, and copper alloys.

Applications of Deep-Draw Stamping Dies

1. Automotive Components

-

Fuel tanks, exhaust systems, and sensor housings.

2. Electronics & Appliances

-

Battery casings, connector housings, and shielding enclosures.

3. Medical & Industrial Equipment

-

Surgical instrument housings, precision fluid containers.

Why Choose Our Deep-Draw Stamping Dies?

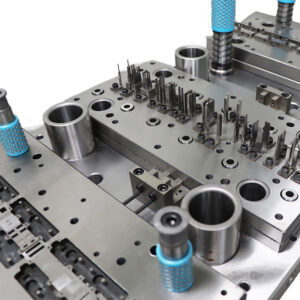

1. Precision Engineering

-

±0.05mm tolerance for critical dimensions.

-

Advanced finite element analysis (FEA) for optimal die design.

2. High-Speed Production

-

Capable of 10,000+ units/day with automated feeding systems.

3. Durability & Longevity

-

Hardened tool steel construction for extended die life.

-

Low-maintenance design reduces downtime.

Learn more about Zhengqiang’s strength

Customized Deep-Draw Stamping Dies

Technical Specifications

| Feature | Details |

|---|---|

| Material Thickness | 0.1mm – 3.0mm (SUS304, Aluminum, Copper) |

| Maximum Draw Depth | Up to 5x material thickness |

| Tolerance | ±0.05mm (critical dimensions) |

| Production Speed | 10,000+ units/day (automated) |