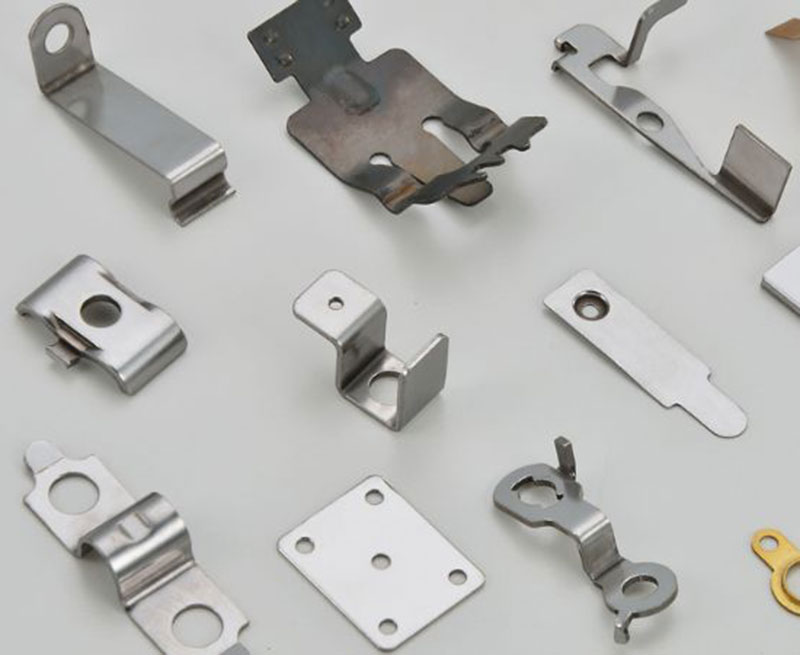

Precision Metal Stamping Parts for High-Performance Applications

Precision metal stamping parts with full customization, fast delivery, and IATF 16949 quality — let us reduce your time and cost.

Precision Metal Stamping Parts by Industry Application

Zhengqiang Technology delivers industry-specific precision metal stamping parts designed for demanding applications. From automotive systems to smart home devices, our components are engineered with tight tolerances, reliable material integrity, and scalable production capabilities — ensuring performance, durability, and cost-efficiency across all use cases.

Automotive Hardware

Zhengqiang provides precision-stamped automotive hardware for critical applications such as battery housing, shielding covers, structural brackets, and connectors. With IATF 16949-certified production and deep drawing expertise, we ensure each component meets the strength, lightweight, and safety demands of modern NEV and traditional vehicle platforms. Our in-house tooling and automation deliver both flexibility and rapid turnaround.

Electronic Components Hardware

Our electronic hardware stamping solutions support applications in consumer electronics, communication devices, and industrial control systems. We specialize in high-precision terminals, heat dissipation plates, shielding shells, and connectors. These parts are produced with micron-level tolerances and undergo strict surface treatment to ensure conductivity, corrosion resistance, and long-term electrical reliability.

Smart Home Hardware

For the growing smart home sector, Zhengqiang manufactures customized metal stamping parts used in sensor housings, device brackets, wall mount plates, and switch modules. We help brands achieve sleek, durable, and precisely assembled components compatible with wireless modules, smart lighting systems, and home automation hubs. From prototyping to large-scale delivery, we support fast product iterations.

Looking for Precision Metal Stamping Manufacturers?

Partner with a trusted precision metal stamping manufacturers to reduce lead times, improve part consistency, and streamline your production. Whether you need custom brackets, shielding parts, or micro-stamped components, we deliver fast, reliable, and high-accuracy solutions.

Get a free consultation today — click below and let’s create the ideal parts for your next project.

Why Choose Zhengqiang Precision Metal Stamping Parts?

At Zhengqiang Technology, we combine advanced manufacturing technology, full-process customization, and global quality assurance to deliver precision metal stamping parts that meet the highest standards in performance, safety, and reliability. We strictly follow IATF 16949 quality standards, implementing rigorous testing and traceability throughout the process. Trusted by leading brands, we help you reduce development time, optimize product structure, and accelerate market success.

Advanced Forming Technology

Our industry-leading deep drawing and cold extrusion processes are among the most advanced in China, enabling lighter, stronger, and safer designs. This empowers manufacturers to optimize product performance across automotive, electronics, and smart device sectors.

Comprehensive Customization Services

From early-stage product design and mold development to high-precision stamping and surface finishing, we offer complete customization services. This integrated approach helps reduce development costs and speeds up time-to-market for our clients.

Scalable Smart Manufacturing

Equipped with intelligent manufacturing systems and imported precision equipment, we ensure consistent, large-scale production with fast turnaround. Our flexible production capacity allows us to meet both high-volume and urgent custom orders.

International-Grade Quality Control

We strictly follow IATF 16949 quality standards, implementing rigorous testing and traceability throughout the process. This ensures that each stamping part is reliable, safe, and enhances your brand’s competitiveness in the global market.

FAQs About Precision Metal Stamping Parts

Precision metal stamping parts are components manufactured by pressing metal sheets into specific shapes using high-accuracy dies. They are widely used in industries like automotive, electronics, and smart devices where tight tolerances, repeatability, and complex geometries are required.

Common materials include stainless steel, copper, aluminum, brass, and high-strength alloys. The choice depends on the application’s strength, conductivity, corrosion resistance, and cost requirements. We help customers select optimal materials based on their specific needs.

We can achieve dimensional tolerances as tight as ±0.01mm, depending on the material, thickness, and part complexity. Our advanced tooling systems and in-line quality checks ensure consistent accuracy even in large-scale production.

Yes. Zhengqiang Technology specializes in custom precision metal stamping solutions for automotive hardware, electronic components, smart home devices, and more. We offer end-to-end support from product design to mass production.

We offer in-house tooling, automated production lines, fast lead times, and strict IATF 16949-compliant quality control. Our integrated approach ensures cost-efficiency, high consistency, and full customization of stamping parts.

Simply contact our engineering team via the inquiry form or email. Provide your part drawings or specifications, and we’ll respond with a tailored solution, lead time estimate, and competitive pricing — with sample support available for evaluation.

Get Custom Precision Metal Stamping Parts

Whether you need high-precision shielding components, deep-drawn brackets, or custom micro-stamped parts, Zhengqiang Technology can deliver tailored precision metal stamping parts to meet your exact application requirements.With strong R&D capabilities, fully automated production lines, and proven experience in the automotive, electronics, and smart hardware industries, we help you reduce lead times, lower costs, and improve product reliability.

Contact our engineering team and get free technical consultation and customized stamping solutions.