- Information Classification

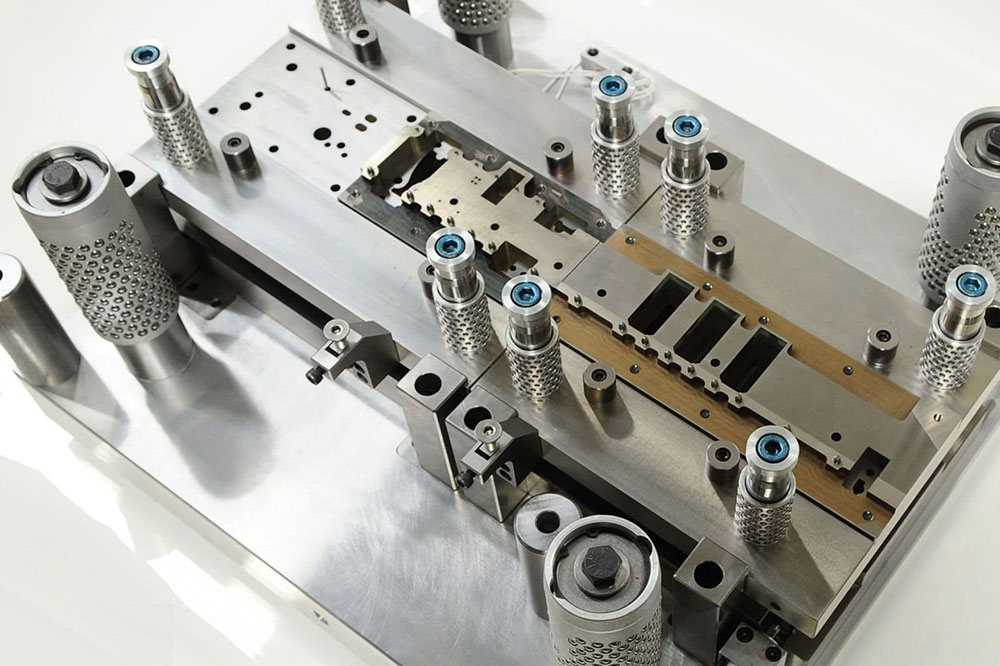

Hardware Mold Supplier | Precision Molds, Reliable Quality

Introduction

In the hardware mold industry, choosing a supplier is not merely about selecting a trading partner, but also about seeking a long-term strategic partner for cooperation. The selection of suppliers directly affects product quality, production efficiency, cost control and the time of final delivery. To make informed decisions in a complex market, it is crucial to understand how to evaluate suppliers and the quality of molds they provide, their technical capabilities and service support.

Through this series of steps, you can ensure that you select the most suitable hardware mold supplier for your needs, providing long-term value for your business.

Part One: Understand your requirements for hardware molds

Section 1.1: Evaluate your mold requirements

Before choosing a hardware mold supplier, it is first necessary to clarify your mold requirements. This includes the following aspects:

- Youdaoplaceholder7 Mold type: Determine the required molds based on the type of products you produce, such as injection molds, stamping molds, die-casting molds, etc.

- Youdaoplaceholder7 Mold materials: Different products and production requirements may require different mold materials, such as steel molds, aluminum molds, etc.

- Mold precision requirements: Evaluate the precision requirements of the product and determine whether a high-precision mold design is needed.

- Mold service life: Determine the expected service life of the mold to assess whether a mold with high durability is required.

Section 1.2: Project and Budget Considerations

After determining the mold requirements, the following factors also need to be considered

- “Quality and Cost Balance: How to control the budget while ensuring mold quality.” Low-cost molds may affect product quality, while high-quality molds may increase initial investment.

- Youdaoplaceholder7 Delivery time: Select suppliers who can deliver on time according to the project schedule.

- Long-term demand: Whether there is a need for long-term cooperation or a one-time purchasing demand. Long-term cooperation may help to obtain more favorable prices and conditions.

Part Two: Research potential suppliers

Section 2.1 : Searching for Suppliers

Potential hardware mold suppliers can be sought through the following methods:

- Attend industry exhibitions and conferences: Participate in industry-related exhibitions, such as the China International Mold Technology Exhibition, etc., and you can directly contact numerous mold suppliers.

- Industry network and Recommendations: Find reliable suppliers through recommendations from peers and business partners.

- Online platforms and directories: Some professional B2B platforms, such as Alibaba, MADEin-china, etc., provide a large amount of information on mold suppliers.

Section 2.2: Evaluation of Supplier Qualifications

After identifying potential suppliers, the next step is to assess their qualifications:

- Certification and qualifications: Check whether the supplier has quality certifications such as ISO, as well as other industry-related certifications.

- Experience and Cases: Learn about the supplier’s experience in the mold field and check if they have successful cases, especially projects similar to yours.

- Customer reviews and word-of-mouth: By reviewing past customer feedback and evaluations, understand the service quality and delivery situation of the supplier.

Part Three: Evaluating the Quality and reliability of hardware molds

Section 3.1: Quality Standards and Compliance

Ensure that the molds of suppliers comply with industry quality standards and compliance requirements. International certifications, such as ISO 9001, etc., are important bases for judging whether the quality management system is perfect.

Section 3.2: Reliability and Timeliness

Evaluate the delivery records and production stability of suppliers. Timely delivery and consistency in product quality are the keys to ensuring the smooth progress of production.

Part Four: Ethical and Sustainable Practices in Metal Mold Manufacturing

Section 4.1 : Ethical Procurement

Ensure that hardware mold supplier adhere to ethical procurement standards, including reasonable labor treatment, a safe working environment, and compliance with human rights norms.

Section 4.2: Environmental Considerations

Choose environmentally conscious suppliers and ensure that they use materials and processes that meet environmental protection requirements.

Part Five: Cost Considerations for Metal Mold Manufacturing

Section 5.1: Negotiation Terms and Prices

When negotiating with hardware mold supplier, it is necessary to ensure the transparency and fairness of prices while taking into account long-term cost-effectiveness.

Section 5.2: Long-term Cost-effectiveness

Analyze the total cost of ownership (TCO), including transportation, warehousing and potential after-sales expenses, to ensure that the selected supplier can provide a cost-effective solution.

Part Six: Relationship Establishment and Maintenance in the Hardware Mold Industry

Section 6.1: Communication and Collaboration

Effective communication is the key to ensuring that Hardware Mold Supplier can understand and deliver molds as required. Regular communication and coordination help ensure the smooth progress of the production process.

Section 6.2: Long-term Partnership

Establishing a long-term and stable cooperative relationship can provide better guarantees in terms of price, quality and delivery. Long-term cooperation also helps suppliers better understand your business needs and provide tailor-made services.

Conclusion

Choosing a suitable hardware mold supplier requires a comprehensive consideration of multiple factors such as technical capabilities, product quality, price, and the reliability of the supplier. By gaining a thorough understanding of the supplier’s background, qualifications and services, you can find a long-term strategic partner to ensure the optimization of product quality, production efficiency and cost control.