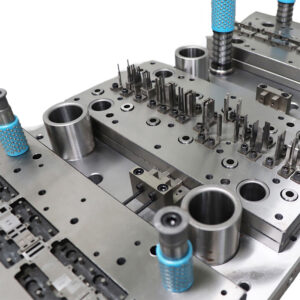

Engineered for memory card sockets, our DDR contacts leverage a "Form-Adjust-Stabilize" design philosophy to overcome critical challenges in multi-angle bending and micro-tolerance control:

Complex Bend Sequencing: 8+ precision bends at ±0.03° angular accuracy, preventing springback deformation.

Dimensional Rigidity: Maintains critical slot dimensions within ±0.015mm under 10,000+ insertion cycles.

Material Integrity: High-phosphor bronze (C5191) with nickel plating ensures 50mΩ contact resistance.

Core Role:

Provides zero-latency electrical connectivity and mechanical retention for DDR4/DDR5 memory modules at speeds up to 6400 MT/s.

Products details

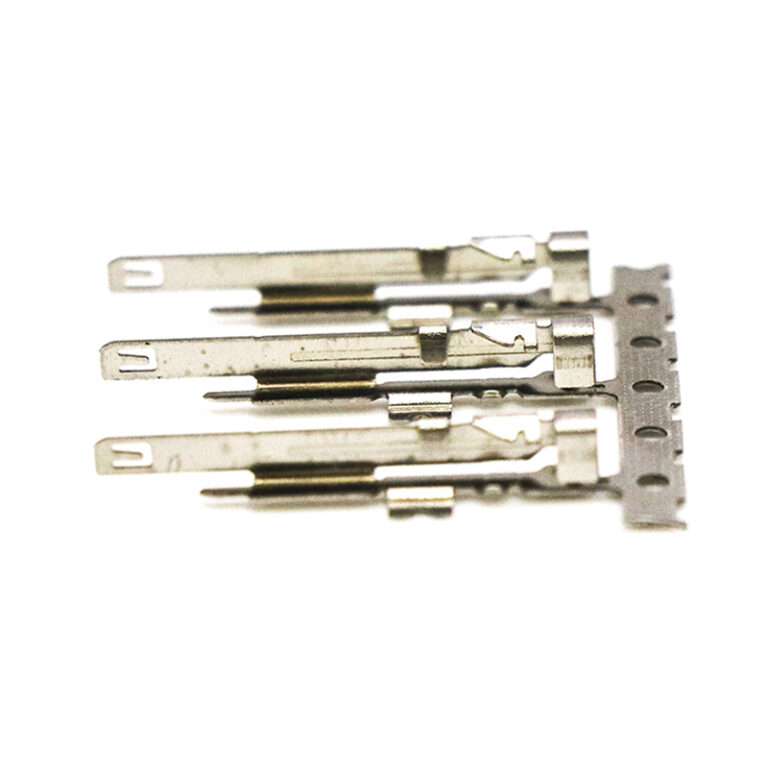

DDR Contact for High-Speed Memory Module Performance

Our DDR contact series is engineered for extreme-speed high-speed memory module performance, delivering exceptional multi-bend stability across DDR4 and DDR5 sockets. These precision components are designed using a proprietary “Form-Adjust-Stabilize” process to overcome springback and micro-deformation, ensuring signal integrity even at 6400MT/s.

Multi-Bend DDR Contact Design for Zero-Latency Stability

Each contact is crafted with over eight precision bends, achieving angular control within ±0.03° to eliminate springback during manufacturing. With ±0.015mm dimensional rigidity under 10,000+ insertion/removal cycles, these guarantee mechanical reliability and electrical consistency in high-frequency environments.

Material Innovation in Products’ Applications

We utilize C5191 high-phosphor bronze with nickel plating to deliver <50mΩ contact resistance and corrosion protection. The smooth mirror EDM finish (Ra ≤ 0.2μm) reduces connector wear by 3x compared to conventional contacts, improving longevity in high-speed memory modules across data centers, embedded systems, and telecom hardware.

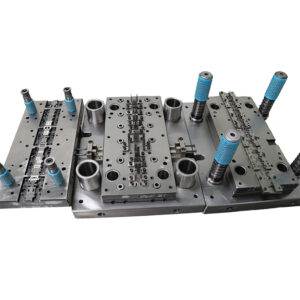

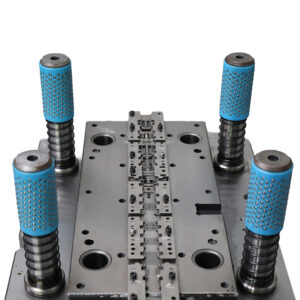

Precision Manufacturing for High-Speed DDR Precision Contacts

Thanks to 0.05mm press brake tolerances and laser-guided bending, our multi-bend structures meet JEDEC MS-304 standards. CCD-based automated optical sorting ensures 99.95% accuracy at over 120,000 units/hour, enabling consistent high-volume delivery without tolerance stacking issues.

Applications

Data Centers: Server RAM sockets, high-density DIMM slots.

Consumer Electronics: Laptop/desktop memory card holders, gaming console modules.

Industrial Computing: Embedded systems, ruggedized storage devices.

Telecom Hardware: 5G base station memory banks.

Why Choose Us

Stability-First Engineering:

Proprietary Form-Adjust process eliminates tolerance stacking errors, improving yield by 25%.

Micro-Bend Mastery:

0.05mm precision press brakes with laser-guided alignment for complex geometries.

Accelerated Testing:

Validated against JEDEC MS-304 standards (humidity/temperature/insertion endurance).

Surface Excellence:

Mirror EDMed contacts achieve Ra 0.2μm smoothness, reducing wear 3X vs. industry average.

Scalable Precision:

Automated optical sorting ensures 99.95% dimensional compliance at 120K units/hour output.

Learn more about DDR4/DDR5 socket specifications from the official JEDEC Memory Standards Library