- Information Classification

Precision Metal Stamping Technology for Automotive Parts

Introduction:

Precision metal stamping technology is a defining capability for automotive accessories suppliers who must deliver high-volume parts with tight tolerances, consistent surface quality, and reliable mechanical performance. As vehicle systems evolve—embracing electrification, variable valve timing, and lighter-weight structures—manufacturers require parts that meet sealing, fatigue and assembly criteria from day one.

Precision metal stamping technology reduces or eliminates secondary machining by producing burr-free edges, flat sealing faces, and accurately formed features directly from the die. Zhengqiang Technology Group applies these advanced methods across engine systems, VVT components, electric vehicle brackets, and electromagnetic brake parts, enabling clients to shorten lead times and improve cost-per-part while meeting strict industry standards.

Understanding Precision metal stamping technology: Core Principles and Methods

What defines Precision metal stamping technology?

Precision metal stamping technology centers on precision control of plastic deformation and shear cutting to create parts with superior dimensional accuracy and surface integrity. Unlike general-purpose stamping that often requires deburring and finishing, precision methods—such as fine blanking, progressive dies, and compound operations—focus on process stability, tight punch-die clearances, and controlled material flow. Equipment choices (mechanical, hydraulic, or servo presses), synchronized feed systems, and die material selection all contribute to the repeatable performance required by automotive components. Precision metal stamping technology is therefore not simply a substitution for other forming methods; it is a high-value, high-efficiency manufacturing approach that improves assembly fit, reduces downstream operations, and enhances end-product lifetime.

Precision metal stamping technology: Material Selection and Metallurgical Considerations

Choosing the right alloys and treatments

Material behavior under forming dictates whether a design is feasible and how a die must be engineered. Precision metal stamping technology commonly uses cold-rolled steels, HSLA grades, stainless steels, aluminum alloys, and copper alloys based on application needs. Each alloy presents trade-offs among strength, ductility, and surface finish. Metallurgical considerations—such as preform annealing, temper control, and post-stamping heat treatment—are essential to control springback and maintain fatigue life. Surface coatings and lubrication strategies also reduce die wear and improve part appearance. Zhengqiang’s engineers evaluate tensile properties, elongation, and microstructure to set forming windows that ensure parts meet operating demands over the full service life.

Precision metal stamping technology: Die Design and Tooling Innovations

Engineering dies for longevity and accuracy

Die design is the backbone of successful production. Precision metal stamping technology demands dies with precise punch-die clearances, stable pilot locations, and optimized strip layout to minimize scrap and prevent misfeeds. Modern tooling innovations include modular die blocks for quicker maintenance, PVD or DLC wear-resistant coatings, embedded sensors that provide realtime pressure and alignment feedback, and precision-ground components to withstand high cycle counts. Advanced simulation—FEA for metal flow and kinematic analysis for sequencing—permits engineers to predict springback and eliminate issues before hardware is cut, reducing trial iterations and accelerating production readiness.

Precision metal stamping technology: Process Control and Production Engineering

From strip layout to press cycle optimization

Turning a well-designed die into a reliable production line requires precise process control. Precision metal stamping technology uses carefully engineered strip layouts to maximize material yield and minimize scrap. Press selection—mechanical or servo—affects motion profiles, and servo presses are often preferred for complex forming due to programmable ram motion and energy efficiency. Closed-loop control of punch force, in-die load sensing, automated coil feeding with tension control, and SPC-based dashboards allow teams to maintain Cp/Cpk targets across millions of cycles. Automated tool changeover and robotic part handling further increase uptime and reduce operator variability in high-volume programs.

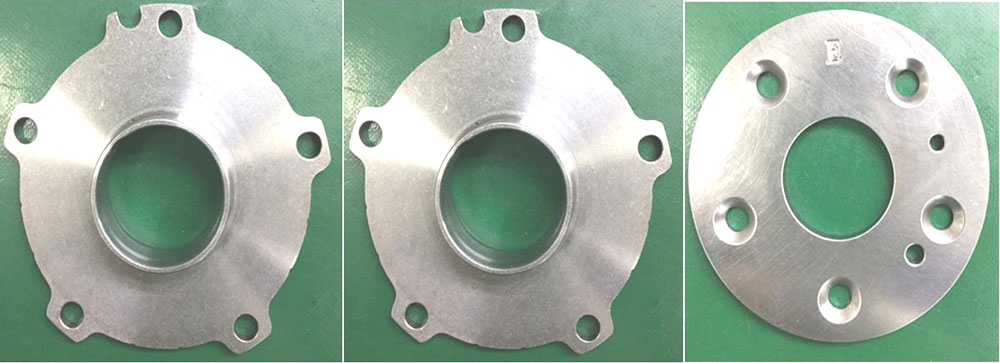

Precision metal stamping technology: Fine Blanking for Cover Plates and High-Integrity Parts

Why fine blanking is a cornerstone method

Fine blanking is an advanced subset of precision stamping that clamps the strip and employs a triple-action shear to deliver mirror-finish, burr-free edges. This process is especially suitable for cover plates, clutch parts, VVT components, and other sealing surfaces that demand excellent flatness and edge quality. The adoption of fine blanking within Precision metal stamping technology transforms the processing chain: parts that once required milling, grinding, or complex deburring can be produced as near-net shapes, reducing cycle time and adding value. The result is improved sealing performance, fewer assembly adjustments, and longer service life for critical automotive components.

Precision metal stamping technology: Automotive Applications and Use Cases

Powertrain, VVT, EV and brake system parts

Precision metal stamping technology is applied broadly across automotive systems. In the powertrain domain, stamping produces VVT control valve components, phaser plates, engine cover plates, and precision brackets that must meet tight tolerances and dynamic loading conditions. For electrified vehicles, stamped busbars, battery pack brackets, weld tabs, and current collectors require electrical conductivity and precise geometry to support thermal and electrical performance. Electromagnetic brake parts and related housings benefit from the burr-free edges and repeatability afforded by precision stamping. Across these use cases, stamping enables scalable production with consistent assembly interchangeability.

Precision metal stamping technology: Quality Assurance and Testing Protocols

Ensuring automotive-grade reliability

Quality assurance for precision-stamped parts combines in-die sensors, dimensional metrology, and destructive testing. Zhengqiang employs CMM measurement, optical inspection, surface integrity analysis, fatigue testing, and salt-spray corrosion evaluation to validate parts against customer criteria. Statistical process control monitors variability, while root-cause investigations and corrective actions maintain capability. Traceability frameworks log material lots, processing parameters, and inspection results to support PPAP and regulatory audits. These layered QA measures ensure stamped components function reliably in safety-critical automotive environments.

Precision metal stamping technology: Automation, Industry 4.0 and Smart Manufacturing

Digitalization to improve predictability and yield

Integrating Industry 4.0 features into stamping operations enhances predictability and throughput. Robotics automate coil loading, blank handling, and stacking; vision systems provide 100% in-line inspection; and IoT sensors monitor die health and press performance. Data aggregation into MES platforms and machine learning models enables predictive maintenance, reducing unplanned downtime and optimizing replacement schedules. By applying digital tools to Precision metal stamping technology, Zhengqiang achieves higher OEE, faster ramp-up, and reliable quality for long production runs.

Precision metal stamping technology: Cost Efficiency, Sustainability and Material Optimization

Reducing waste, energy, and total cost

One of the strategic advantages of precision stamping is material efficiency. Compared with subtractive methods, stamping reduces scrap through optimized nesting, multi-up progressive dies, and coil-fed workflows. Energy-efficient servo presses and closed-loop coolant systems reduce power use and fluid waste. Zhengqiang emphasizes recyclable materials and processes that lower environmental footprint while maintaining competitive economics. The combined effect is lower per-part cost, reduced secondary processing, and an improved sustainability profile for automotive programs.

Precision metal stamping technology: Lifecycle Support and Die Refurbishment

Extending tooling life to protect ROI

Die maintenance and refurbishment are essential components of maintaining production efficiency. Zhengqiang provides scheduled preventive maintenance, in-die wear monitoring, and refurbishment services such as regrinding, bushing replacement, re-hardening, and coating renewal. For design evolutions, dies can be re-engineered to add stations or adapt to new materials. Rapid spare part provisioning and on-site technical response minimize downtime. These lifecycle services keep lines running and preserve capital investment across successive product generations.

Precision metal stamping technology: Manufacturing Capacity, Labs and Case Studies

From prototype to mass production with validated testing

Zhengqiang’s manufacturing footprint includes high-capacity presses, servo lines, automated feeders, and dedicated inspection cells. In a recent VVT phaser program, a progressive die solution combined with servo-press control reduced scrap and stabilized part flatness through the ramp-up phase. Our laboratories enable formability trials, high-cycle fatigue testing, metallurgical analysis, and advanced metrology (CMM, optical scanning). These capabilities speed validation of process parameters and material choices so that volume production proceeds with predictable quality.

Precision metal stamping technology: Collaboration, Training and Continuous Improvement

Design-for-manufacturing and workforce excellence

Early-stage collaboration is key to minimizing rework and accelerating time to market. Zhengqiang engages customers in DFMA reviews, prototype validation, and pilot runs to optimize tolerances, coatings, and assembly behavior. Continuous improvement programs and operator training—covering lean practices and die maintenance—support consistent execution on the shop floor. This culture of improvement ensures that manufacturing knowledge is retained and applied across projects, strengthening the delivery of high-quality stamped parts.

Future Trends and Innovation in Precision metal stamping technology

Adaptive tool materials, in-die sensing, and hybrid manufacturing methods are shaping future capabilities. Innovations that combine laser trimming, additive features in tooling, and automated compensation will enable more intricate geometries and tighter tolerances with minimal manual intervention. Zhengqiang is piloting projects that fuse traditional fine blanking with advanced trimming to create parts that meet next-generation vehicle specifications while accelerating ramp-up and reducing overall tooling cycles.

Why Choose Zhengqiang for Precision metal stamping technology?

Zhengqiang Technology Group delivers vertically integrated solutions—material sourcing, die design, prototyping, precision stamping, heat treatment, surface finishing, and global logistics. Our domain experience spans internal combustion and new-energy vehicles, heavy trucks, motorcycles, electromagnetic brakes, and industrial tools. We maintain automotive-grade quality systems, full material traceability, and collaborative engineering to optimize costs and time-to-market. By partnering with Zhengqiang, OEMs and tier suppliers gain a stamping partner capable of taking programs from feasibility to mass production with predictable yield and quality.

Conclusion and Call to Action

Precision metal stamping technology is a strategic differentiator for automotive programs that require high-precision, high-volume metallic components. From fine blanked cover plates to busbars and VVT parts, the right combination of material science, die engineering, process control, and lifecycle support determines program success. Zhengqiang invites you to explore a partnership—request a feasibility study, tooling proposal, or sample run. Contact our engineering team today to discuss how our capabilities can lower costs, improve yield, and accelerate your next automotive program.

Contact Zhengqiang Technology Group now for a confidential consultation, tailored feasibility study, and sample evaluation—let’s stamp precision into your next product.

FAQ (Selected Questions for Buyers)

Q1: What is the primary advantage of Precision metal stamping technology?

A1: It produces burr-free, dimensionally stable parts with minimal secondary finishing—reducing cost and improving assembly consistency.

Q2: Can Zhengqiang produce fine-blanked cover plates and VVT components?

A2: Yes. We specialize in fine blanking and supply cover plates, phaser plates, and VVT parts that meet tight tolerances.

Q3: What materials are typically used in precision stamping for automotive parts?

A3: Cold-rolled steels, HSLA, stainless steels, aluminum alloys, and copper alloys are commonly used; selection depends on strength, formability, and function.

Q4: How long does new die development usually take?

A4: Typical lead times range from 6–10 weeks, depending on complexity and iteration needs; rapid prototyping options are available.

Q5: Do you provide die maintenance and refurbishment?

A5: Yes. We offer preventive maintenance, on-site refurbishment, regrinding, and parts provisioning to minimize downtime.

Q6: How is traceability handled for automotive programs?

A6: We maintain full material lot traceability, process logging, and serialization to meet PPAP and regulatory requirements.