Product Description:

Key Specifications

Material: DC04 Cold-Rolled Steel (EN 10130 compliant)

Thickness: 2.0mm ±0.02mm

Critical Tolerances:

Outer Diameter: ±0.05mm

Inner Diameter: ±0.03mm

Surface Integrity:

Sheared bright band ≥60% (burr-free edge)

Dual-side chamfering (R0.2±0.05mm)

Products details

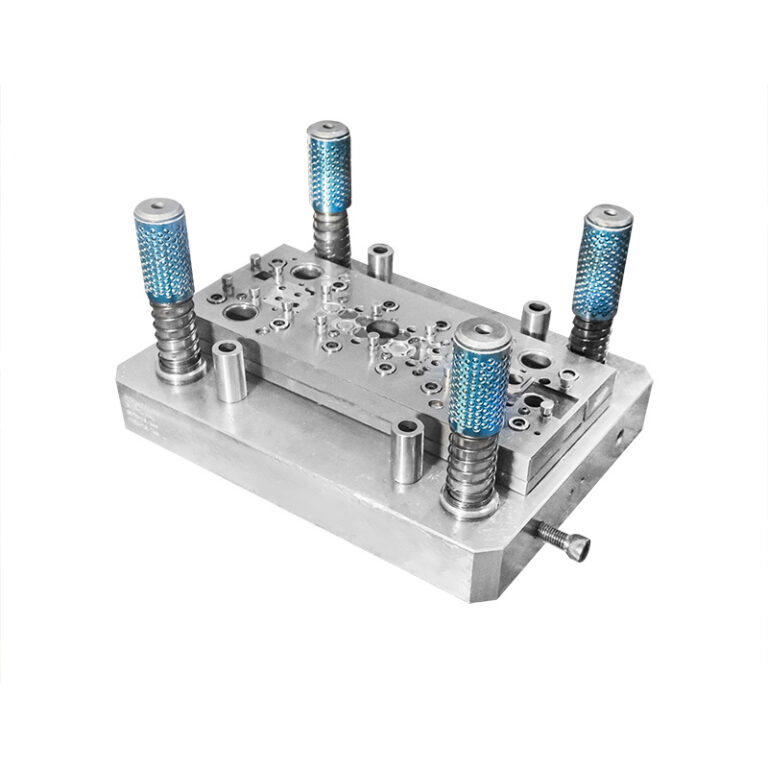

Advanced Manufacturing Process

Progressive Die Stamping Technology

Dual-output Layout: Simultaneous forming of 2 units per stroke

Integrated In-Die Chamfering: Front/back deburring in single operation

Speed: 80 SPM (76,800 units/day at 16-hour production)

Quality Assurance

Statistical Control: CPK ≥1.67 (validated with 300k-unit production data)

Edge Quality Verification: White-light interferometry for bright band ratio

100% Automated Optical Inspection (AOI): Real-time OD/ID tolerance monitoring

Solving Industry Challenges

| Traditional Pain Points | Our Breakthrough |

| Secondary chamfering causes deformation | Single-step in-die dual-side chamfering |

| Single-station efficiency ≤35 SPM | 80 SPM continuous production |

| Tolerance fluctuation >0.1mm | ±0.03mm consistency via air-floating guides |

| Bright band <50% | Precision clearance control + TiN-coated blades |

Applications

Electric Vehicles: Motor end covers, battery module shielding

Traditional Autos: Generator coil guards, sensor housings

Industrial Motors: Stator insulation covers for high-power motors

Ideal for EMI-sensitive components requiring mechanical protection

Why Choose Us

Mass Production Excellence

Full-servo presses: Dynamic accuracy ±5μm

AI-driven wear compensation: Tool life extended to 3M+ strokes

Cost Efficiency

92% material utilization (nesting optimization + dual-output)

Zero secondary processing: 37% unit cost reduction

Automotive Certification

IATF 16949 certified manufacturing

Dimensional reports aligned with VDA 5 standards