- Information Classification

Precision Metal Processing | Complete 2025 Guide & Solutions

Author | Zhengqiang Industry Insights Team

Updated | December 2025

Introduction:

Precision Metal Processing has become one of the most essential manufacturing technologies across modern industries—from automotive electronics and EV components to consumer electronics, medical devices, aerospace parts, and smart manufacturing. As global demand for high-precision components continues to rise, understanding the core concepts, processes, technologies, and real-world applications of Precision Metal Processing becomes crucial for buyers, engineers, and decision-makers.

In this 2025 complete guide, we explore what Precision Metal Processing truly means, how it works, its manufacturing steps, benefits, applications, and why companies across the world increasingly choose Chinese manufacturers such as Zhengqiang Technology Group for high-accuracy metal components.

What Is Precision Metal Processing? (Precision Metal Processing Defined)

Precision Metal Processing refers to the manufacturing of highly accurate metal parts with extremely tight tolerances, often within ±0.05mm or even smaller. These parts are commonly used in industries requiring exceptional performance, durability, and consistency. Compared with ordinary metal fabrication, Precision Metal Processing focuses on micro-level accuracy, advanced equipment, automated production, and strict quality control.

The goal of Precision Metal Processing is to ensure that every component meets exact specifications—including dimensions, flatness, angles, roughness, and mechanical properties. For industries such as automotive connectors, precision motors, EV components, capacitors, and electronics, achieving accuracy and repeatability is critical to ensuring stable performance and long service life.

Types of Precision Metal Processing (Precision Metal Processing Methods)

Precision Metal Processing includes a wide range of advanced techniques used to produce metal parts that meet strict industry standards. The major technologies include:

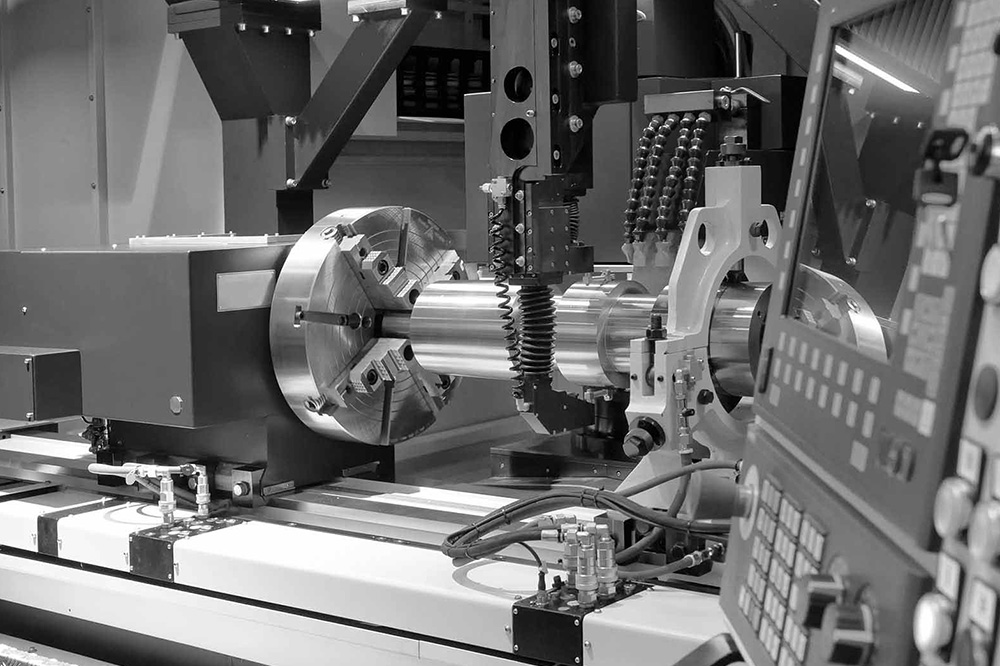

CNC Machining in Precision Metal Processing

CNC machining is widely used to produce small, complex, high-accuracy components. It uses computer-controlled equipment to ensure that every cut, groove, and dimension meets design specifications. CNC machining is essential for creating high-precision metal housings, connectors, shafts, mechanical parts, and electronic components.

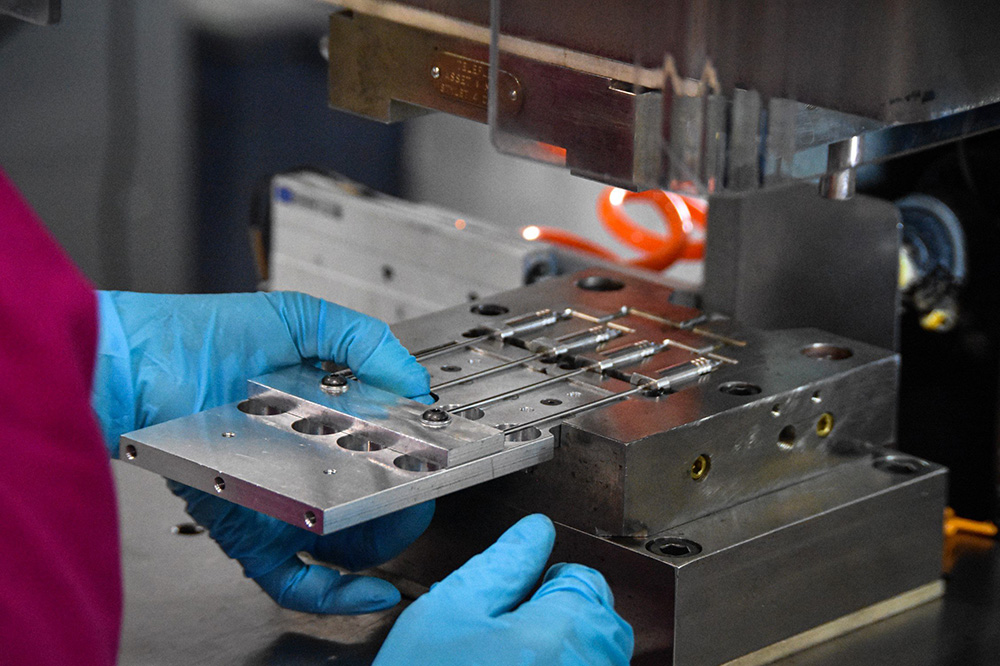

Precision Metal Stamping

Precision stamping is ideal for producing lightweight, thin, and high-accuracy metal parts in large quantities. With advanced progressive dies and high-speed presses, stamping offers exceptional repeatability and cost efficiency. It is commonly used for terminals, shrapnel, brackets, clips, frame components, and automotive connectors.

Precision Turning (Lathe Processing)

Precision turning produces cylindrical or round-shaped components such as pins, shafts, fasteners, motor parts, and custom round connectors. It ensures excellent roundness control and surface finishing, which are critical for mechanical sealing and movement.

Sheet Metal Precision Fabrication

This includes laser cutting, bending, welding, forming, and finishing. Sheet metal precision processing is widely used for electrical cabinets, enclosures, brackets, metal frames, and custom mechanical housings.

Key Features of Precision Metal Processing (Core Advantages)

Precision Metal Processing delivers several unmatched benefits that traditional fabrication methods cannot achieve:

-

Ultra-tight tolerances, often within ±0.05mm or even ±0.01mm

-

High repeatability, ensuring consistent quality—even for millions of units

-

Superior surface finishing, minimizing friction and improving performance

-

Compatibility with automation, enabling efficient large-scale production

-

Support for complex geometries, including micro-holes, thin walls, and multi-structure designs

These advantages make Precision Metal Processing essential for industries that demand superior electrical conductivity, mechanical stability, and long-term reliability.

Understanding the Full Workflow of Precision Metal Processing in 2025

Precision Metal Processing follows a detailed and highly controlled production workflow. Below is a step-by-step explanation:

Step 1 – Reviewing Drawings, Requirements & Specifications

Before processing begins, engineers must analyze 2D/3D drawings, materials, tolerances, thickness, and performance requirements. This ensures that the correct tools, dies, parameters, and machines are selected. For high-precision components, even a small misunderstanding can lead to production failure.

Step 2 – Raw Material Selection & Cutting

Materials such as stainless steel, copper alloys, aluminum, high-strength steel, or titanium are selected based on product requirements. Raw materials are cut using laser cutting, sawing, or shearing to prepare for machining or stamping.

H3: Step 3 – High-Precision Processing & Manufacturing

This is the core stage of Precision Metal Processing. Depending on the design, CNC machining, stamping, turning, bending, or multi-step automated processing is performed to achieve accurate dimensions and structural precision.

Step 4 – Surface Treatment & Finishing

Surface treatments such as polishing, anodizing, electroplating, spraying, and passivation improve corrosion resistance, conductivity, and aesthetic appearance. For electronic parts, surface finishing may include gold plating, silver plating, tin plating, or nickel plating.

Step 5 – Quality Inspection & Assembly

Before parts are delivered, strict inspections are conducted using equipment such as CMM, projectors, hardness testers, and high-precision gauges. Only components that fully meet specifications are passed for assembly or packaging.

Applications of Precision Metal Processing Across Industries

In 2025, Precision Metal Processing plays a critical role in multiple sectors:

-

Automotive connectors & terminals

-

EV charging components & new-energy systems

-

Motors & motor housings

-

Consumer electronics and smart devices

-

Medical components & surgical instruments

-

New-energy capacitors & electronics parts

-

Industrial automation & robotics components

With increasing demand for miniaturization, lightweight designs, and improved performance, Precision Metal Processing has become a core technology driving global manufacturing growth.

Why Choose Zhengqiang Technology Group for Precision Metal Processing?

Zhengqiang Technology Group stands out as one of China’s trusted suppliers in Precision Metal Processing thanks to:

-

20+ years of experience in metal components

-

Advanced CNC, stamping, and mold tooling equipment

-

In-house R&D for new materials and structural designs

-

Strict quality systems with 100% inspection capability

-

Fast delivery, stable supply, and competitive pricing

-

Strong engineering support for custom OEM/ODM projects

Whether you require precision terminals, high-frequency connectors, motor components, stamped brackets, or custom mechanical assemblies, we deliver reliable and cost-effective solutions.

FAQ About Precision Metal Processing

Q1: What tolerance can be achieved with Precision Metal Processing?

Our precision machining and stamping processes can achieve tolerances as tight as ±0.01–0.05mm.

Q2: Can you support large-volume mass production?

Yes. We provide fully automated machining, stamping, and inspection systems for high-volume production.

Q3: What materials can be used?

Stainless steel, copper, beryllium copper, aluminum, alloy steel, titanium, and more.

Q4: Do you offer surface treatment services?

Yes. Electroplating, anodizing, polishing, sandblasting, powder coating, and chemical passivation are available.

Conclusion:

Precision Metal Processing continues to shape the future of global manufacturing, supporting industries that demand accuracy, efficiency, and advanced engineering performance. As businesses seek reliable partners, choosing a manufacturer with technical strength, strict quality control, and advanced automation is critical.

Zhengqiang Technology Group is ready to support your next project with stable quality, competitive pricing, and precision you can rely on.

Contact us today to discuss your Precision Metal Processing requirements!