- Information Classification

Micro Metal ID Stamp: Complete Guide for 2025

Author | Zhengqiang Industry Insights Team

Updated | December 2025

Introduction: What is Micro Metal ID Stamp?

Micro metal ID stamping has become a pivotal technology in the manufacturing industry, providing businesses with the ability to mark and identify small-scale metal parts with precision and durability. This advanced process involves the creation of unique identifiers or codes on metal surfaces using specialized tools. Whether you’re in the electronics industry, automotive sector, or precision manufacturing, Micro Metal Ma has proven its value in tracking and ensuring quality control across various products. But what makes this process so critical, and why should it be a consideration for businesses looking to enhance their manufacturing operations?

Understanding Micro Metal ID Stamping: How It Works

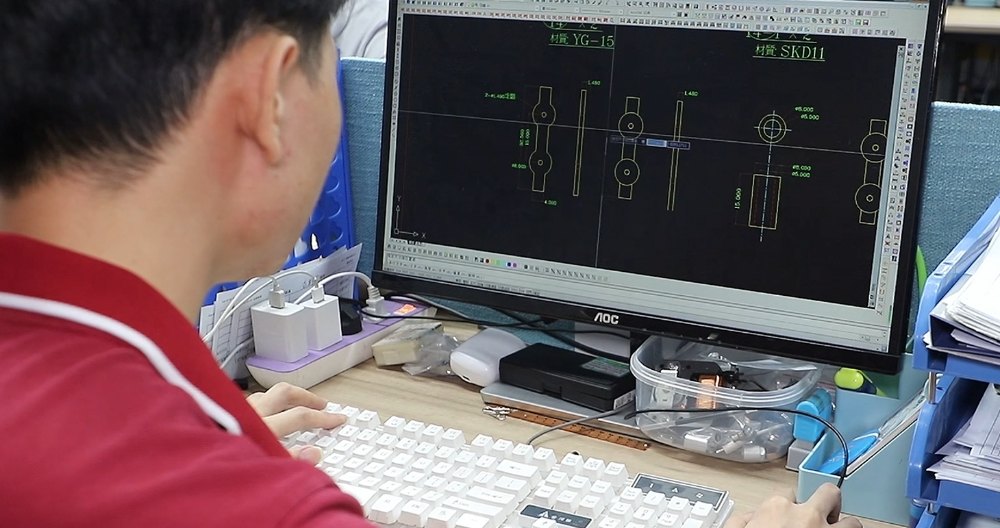

Micro metal ID stamping utilizes highly advanced machinery to imprint an identification number, serial code, or logo onto metal parts. This process is usually performed using a stamping die that presses into the surface of the metal, resulting in a permanent, legible marking that can withstand wear and tear over time.

-

Precision Technology: The technology behind Micro Metal Engraving is engineered to ensure that each mark is crisp, clear, and of high quality. The die is designed to create a permanent indentation without compromising the integrity of the material.

-

Applications: Micro metal ID stamping is used across industries that require secure, traceable identification, such as:

-

Electronics Manufacturing: Ensuring each component is traceable.

-

Automotive Industry: For serial numbers on engine components.

-

Medical Equipment: For tracking components and ensuring compliance.

-

Micro Metal Engraving stamps are beneficial for tracking parts through the manufacturing process and in the post-production lifecycle. They help ensure that parts are easily identifiable, even when subjected to harsh environments or extensive wear.

Benefits of Micro Metal ID Stamping

There are several benefits to utilizing Micro Metal Engraving technology in your business, including:

-

Durability: The markings created by micro metal ID stamps are permanent and can withstand high temperatures, corrosion, and other environmental conditions, making them ideal for industrial applications.

-

Precision and Accuracy: The ability to create extremely fine and detailed markings ensures that the ID code is readable even on very small parts, which is particularly important for businesses dealing with microelectronics or miniature components.

-

Cost-Efficiency: While some other marking methods, like laser engraving, may be more expensive, micro metal ID stamping is often a more cost-effective solution for manufacturers, especially when large volumes of parts need to be marked.

-

Compliance and Tracking: With increasingly stringent regulations, particularly in industries like healthcare and automotive, having a traceable identifier on each part ensures compliance and improves tracking capabilities.

Micro Metal ID Stamp Applications in Various Industries

Electronics Industry

In the electronics industry, micro metal ID stamps are commonly used to mark electronic components such as resistors, capacitors, and microchips. This is vital for both quality control and traceability. By marking each part with a unique identifier, manufacturers can track components from production to installation, ensuring that any defective parts can be quickly identified and replaced.

Automotive Industry

For the automotive industry, micro metal ID stamping is used extensively in the marking of engine components, structural parts, and even safety features like airbags and seat belts. These stamps allow for the identification of each part in case of recalls, providing manufacturers with a quick and efficient way to trace issues back to the source.

Aerospace Industry

Aerospace components are often subject to extreme conditions, so durability is crucial. Micro metal ID stamping is used to mark everything from turbine blades to structural beams, ensuring that each part can be identified for maintenance, replacement, and regulatory compliance purposes.

Medical Equipment

In medical device manufacturing, it is essential to track components for safety and quality assurance. Micro metal ID stamps are used to mark parts with serial numbers or batch numbers, ensuring that each part can be traced throughout the lifecycle of the device, and providing documentation for regulatory bodies.

Why Choose Zhengqiang Technology Group for Your Micro Metal ID Stamping Needs?

Zhengqiang Technology Group is at the forefront of high-tech manufacturing solutions. As a company specializing in precision components, including micro metal ID stamping, we are committed to delivering high-quality, durable products that meet the stringent demands of industries like automotive, aerospace, electronics, and medical devices.

Why Choose Us?

-

Cutting-Edge Technology: We employ the latest advancements in stamping technology to ensure precision, accuracy, and durability in every project.

-

Experienced Team: With years of expertise in the industry, we understand the unique needs of each sector and provide tailored solutions.

-

Global Reach: We offer global sales and support, ensuring that our solutions are accessible wherever you are.

-

Quality Assurance: Our commitment to quality control ensures that each micro metal ID stamp is created to the highest standards, meeting international regulations and certifications.

By choosing Zhengqiang Technology Group, you are choosing a partner who understands the importance of precision and reliability in every component.

Frequently Asked Questions (FAQ)

What is the difference between micro metal ID stamping and laser engraving?

Micro metal ID stamping involves physically pressing a die into the metal, creating a permanent indentation. Laser engraving, on the other hand, uses a laser to burn a mark into the material. While both are permanent, stamping is typically faster and more cost-effective for high-volume production.

Can micro metal ID stamping be used on all types of metals?

Micro metal ID stamping is versatile and can be used on a wide variety of metals, including steel, aluminum, brass, and titanium. However, the specific metal type may affect the depth and quality of the mark, which is why testing is recommended for new materials.

Is micro metal ID stamping suitable for small components?

Yes, micro metal ID stamping is specifically designed for marking small components. The technology allows for highly detailed marks to be created on very small parts, making it ideal for industries like electronics and precision manufacturing.

How do I ensure the durability of the stamp on my parts?

The durability of the stamp largely depends on the quality of the stamping die and the material being marked. Zhengqiang Technology Group uses advanced techniques and materials to ensure that your micro metal ID stamps remain clear and legible even under harsh conditions.

Conclusion: The Future of Micro Metal ID Stamping

Micro metal ID stamping has become an indispensable part of modern manufacturing. It offers a robust, cost-effective, and highly durable method for marking metal parts in a variety of industries. Whether you’re in the automotive, aerospace, electronics, or medical sectors, micro metal ID stamping can provide a solution for precise part identification, traceability, and compliance.

At Zhengqiang Technology Group, we specialize in delivering high-quality micro metal ID stamps tailored to your needs. Our cutting-edge technology, combined with our expertise, ensures that you get the best possible solution for your business.

Call to Action:

Looking for precise and reliable micro metal ID stamping for your business? Contact Zhengqiang Technology Group today for a consultation and find out how our solutions can elevate your manufacturing process