- Information Classification

2025 Outer Rotor BLDC Motor: High-Efficiency Vehicles &

Author | Zhengqiang Industry Insights Team

Updated | December 2025

In the world of electric motors, the Outer Rotor BLDC Motor (Brushless DC Motor) stands out as an innovative and highly efficient option. It has been increasingly adopted across various industries, including robotics, automotive, and home appliances, due to its superior efficiency, reliability, and compact design. This guide will take you through the essentials of Outer Rotor BLDC Motors, their benefits, applications, and the reasons why they are the preferred choice for many manufacturers.

Chapter 1: Understanding the Outer Rotor BLDC Motor

What is an Outer Rotor BLDC Motor?

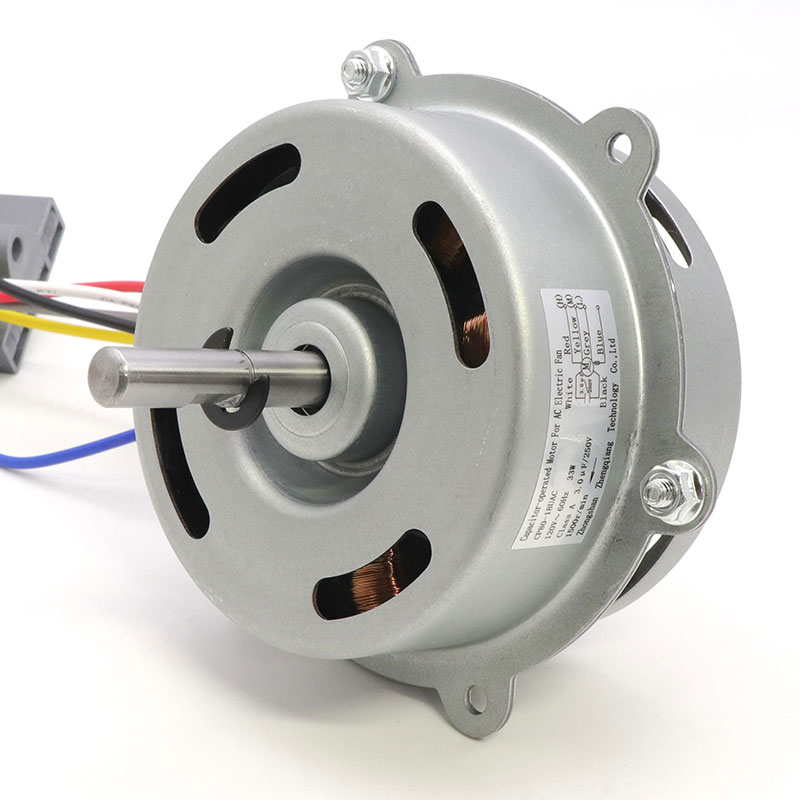

An Outer Rotor BLDC Motor is a type of brushless DC motor where the rotor (the rotating part of the motor) is positioned on the outside of the stator (the stationary part). Unlike traditional motors, which have the rotor in the center, the outer rotor design allows for more efficient torque production and a higher power-to-weight ratio.

BLDC (Brushless DC) motors are powered by a permanent magnet rotor, and they eliminate the need for brushes and a commutator, which are commonly found in traditional brushed motors. This design reduces wear and tear and improves the motor’s longevity and reliability.

Outer Rotor vs. Inner Rotor BLDC Motor

The key difference between an Outer Rotor BLDC Motor and an inner rotor BLDC motor lies in the rotor’s placement. The outer rotor design typically offers higher torque and efficiency because the rotor is larger, and the distance from the rotor to the stator is greater, which leads to improved performance at high speeds.

Chapter 2: Key Benefits of Outer Rotor BLDC Motors

1. Higher Efficiency

The Outer Rotor BLDC Motor has a significantly higher efficiency than traditional brushed motors. Its design minimizes energy loss due to friction and heat, making it more energy-efficient. This translates to lower power consumption, which is critical in applications where energy efficiency is paramount, such as in electric vehicles (EVs) and renewable energy systems.

2. Enhanced Torque-to-Weight Ratio

The Outer Rotor BLDC Motor provides a superior torque-to-weight ratio. Since the rotor is positioned on the outer side, the motor has a larger diameter, enabling the use of larger magnets and resulting in better torque output. This makes it ideal for applications requiring high torque at relatively low speeds.

3. Longer Lifespan and Durability

By eliminating brushes, an Outer Rotor BLDC Motor has fewer moving parts, which means less wear and tear. This contributes to a longer lifespan compared to brushed motors. Its durability is a significant advantage, especially in harsh environments or applications where the motor is in constant use, such as in precision electronics, home appliances, or automotive motors.

4. Quiet Operation

Another key benefit of the Outer Rotor BLDC Motor is its quiet operation. The absence of brushes means less mechanical noise, making it ideal for applications where noise reduction is critical, such as in medical devices or consumer electronics.

Chapter 3: Applications of Outer Rotor BLDC Motors

1. Electric Vehicles (EVs)

One of the most significant applications of the Outer Rotor BLDC Engine is in electric vehicles. Its high torque density, compact design, and efficiency make it the ideal choice for powering electric cars, scooters, and bikes. With increasing demand for green and energy-efficient transportation, the Outer Rotor BLDC Engine plays a crucial role in the success of EVs.

2. Robotics

In robotics, precision, torque, and efficiency are critical. The Outer Rotor BLDC Engine is used in robotic arms, drones, and other automated systems, where high performance and reliability are paramount. Its ability to provide high torque at low speeds is particularly valuable in applications requiring precise movements and control.

3. Home Appliances

Home appliances, such as washing machines, vacuum cleaners, and air conditioners, benefit from the Outer Rotor BLDC Engine’s efficiency and quiet operation. These motors contribute to lower energy bills and a more environmentally friendly operation, which is an increasing concern among consumers.

4. HVAC Systems

In Heating, Ventilation, and Air Conditioning (HVAC) systems, energy efficiency is a priority. The Outer Rotor BLDC Engine helps reduce energy consumption while maintaining optimal performance in fans, pumps, and blowers. Its durability and quiet operation are additional benefits for HVAC manufacturers.

5. Industrial Equipment

Many industrial applications require reliable, high-performance motors. The Outer Rotor BLDC Motor is used in CNC machines, conveyor belts, and other industrial machinery that require constant, high-torque operation.

Chapter 4: Why Choose Zhengqiang Technology Group for Your Outer Rotor BLDC Motor Needs?

Expert Engineering & Manufacturing

Zhengqiang Technology Group is a leader in the field of precision parts manufacturing and specializes in developing cutting-edge solutions for Outer Rotor BLDC Engine With years of experience and advanced technology, we provide motors that are built for maximum efficiency and durability.

Global Reach & Custom Solutions

We understand the unique needs of our global clientele, from electronics manufacturers to automotive giants. Whether you’re designing a new electric vehicle motor or developing robotic systems, Zhengqiang Technology Group offers customized Outer Rotor BLDC Engine solutions to fit your specific needs.

Quality Assurance

At Zhengqiang, we are committed to delivering only the highest quality products. All of our Outer Rotor BLDC Engine undergo rigorous testing to ensure they meet the industry’s highest standards for performance, safety, and reliability. Our customers can rely on us for consistent, high-quality performance.

FAQ: Frequently Asked Questions About Outer Rotor BLDC Engine

1. What is the difference between an Outer Rotor and Inner Rotor BLDC Engine?

The main difference lies in the positioning of the rotor. In an Outer Rotor BLDC Engine, the rotor is located outside the stator, which generally results in higher torque and better efficiency, especially at high speeds. The Inner Rotor BLDC Motor has the rotor located inside the stator, often leading to smaller and lighter designs but with lower torque.

2. What are the key advantages of using Outer Rotor BLDC Motors?

The primary benefits of Outer Rotor BLDC Motors include higher efficiency, improved torque-to-weight ratio, longer lifespan, and quieter operation. These advantages make them ideal for applications such as electric vehicles, robotics, and industrial equipment.

3. Can Outer Rotor BLDC Motors be used in electric vehicles?

Yes, Outer Rotor BLDC Motors are commonly used in electric vehicles due to their high torque, efficiency, and compact design. They help improve the overall performance of EVs, making them more energy-efficient and reliable.

4. How long do Outer Rotor BLDC Motors typically last?

With fewer moving parts and no brushes, Outer Rotor BLDC Motors tend to have a longer lifespan compared to brushed motors. Proper maintenance and care can ensure their longevity, often exceeding tens of thousands of operating hours.

5. Are Outer Rotor BLDC Motors more expensive?

Although Outer Rotor BLDC Motors may have a higher upfront cost compared to traditional brushed motors, their long-term benefits—such as lower energy consumption, reduced maintenance, and extended lifespan—make them a cost-effective choice in the long run.

Conclusion: Embrace the Future with Outer Rotor BLDC Motors

As industries continue to demand more efficient, reliable, and high-performance solutions, the Outer Rotor BLDC Motor stands as a game-changer. Whether you are in the electric vehicle industry, robotics, or home appliances, these motors offer superior torque, efficiency, and durability. At Zhengqiang Technology Group, we specialize in providing advanced, custom-designed Outer Rotor BLDC Motors that can help take your products to the next level.

Call to Action: Contact Us Today!

Looking for the perfect Outer Rotor BLDC Motor for your next project? Contact Zhengqiang Technology Group for reliable, high-performance motors that fit your needs. Let us help you bring your ideas to life with our expertise and cutting-edge technology. Get in touch now!