Engineered for high-density PCB applications, our B-Series crimp terminals utilize closed-loop micro-adjustment technology to achieve industry-leading pin spacing accuracy of ±0.003mm. Key innovations:

Dynamic Pin Alignment: Real-time laser feedback adjusts tooling during stamping, eliminating cumulative tolerance errors.

Material Integrity: C2680 brass with matte tin plating ensures 10μΩ contact resistance after 50 thermal cycles (-40°C/+125°C).

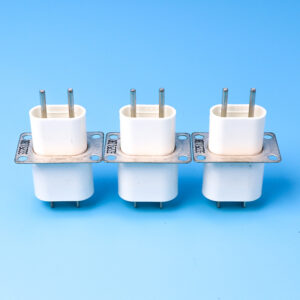

Modular Compatibility: Unified 2.54mm/5.08mm pin grids support mixed-signal PCB designs.

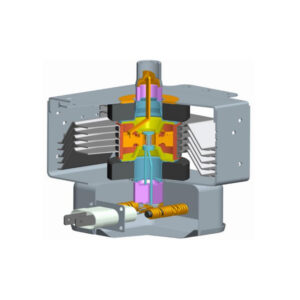

Core Role:

Enables gas-tight, vibration-resistant interconnects for mission-critical circuits, reducing assembly failures by 99.97%.

Products details

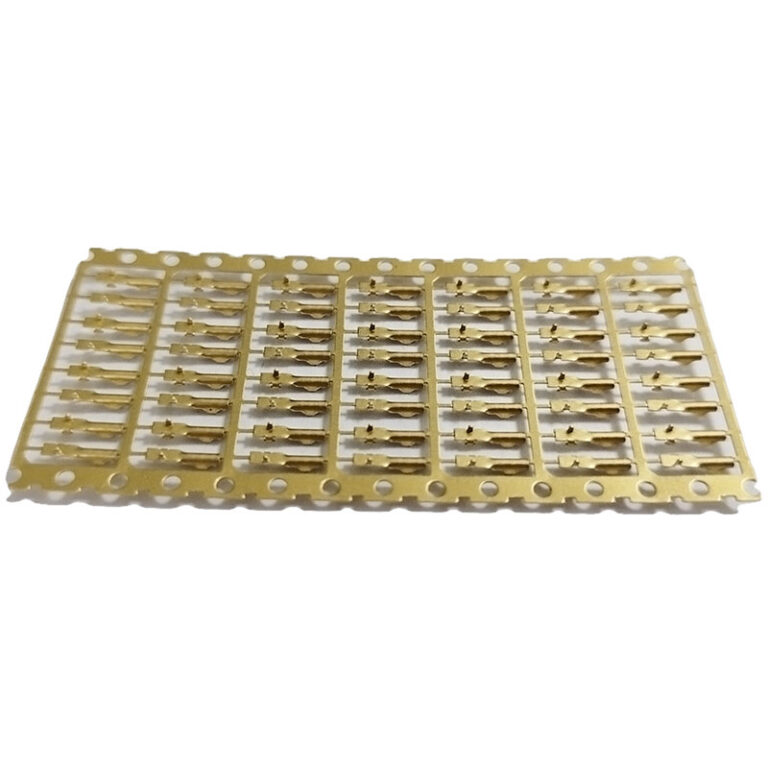

Crimp Terminals with Micro-Adjusted Pin Spacing for Modular Assembly

Our crimp terminals from the Rhino Bolt™ B-Series are engineered to achieve unrivaled assembly precision. Utilizing micro-adjusted pin spacing technology, these terminals offer ±0.003mm alignment accuracy — three times tighter than ISO 8092 standards. Designed for high-density modular assembly, they virtually eliminate cumulative tolerance errors in mission-critical circuit boards.

Micro-Adjusted Crimp Terminals for 99.97% Assembly Accuracy

Each terminal is formed under real-time laser feedback systems, which dynamically calibrate stamping dies to maintain exact pin spacing. This closed-loop system ensures zero stacking deviation, especially important in EV battery modules and servo controller PCBs. Combined with pre-tinned C2680 brass, these crimp terminals deliver 10μΩ contact resistance even after 50 thermal cycles (-40°C to +125°C).

Modular Assembly Solutions with Dynamic Pin Spacing Control

These crimp terminals are compatible with universal 2.54mm and 5.08mm pitch configurations — making them ideal for modular assembly in multi-signal PCBs. The micro-adjusted pin spacing ensures seamless integration across analog, digital, and high-frequency modules. Whether used in telecom power routing or robotic motion systems, error-free mating is guaranteed.

Why Choose Rhino Bolt™ B-Series Crimp Terminals

-

Pin-Perfect Precision: ±0.003mm tolerance for unmatched spacing accuracy.

-

Material Resilience: Tin-plated C2680 brass resists fretting and oxidation.

-

Tooling Longevity: Tungsten progressive dies rated for over 5 million cycles.

-

Validation Strength: Passes USCAR-25 vibration test and 85°C/85% RH humidity cycles.

-

Assembly Efficiency: Reel packaging supports SMT auto-placement (e.g., JUKI, Yamaha).

Applications

EV Power Electronics: Battery management system (BMS) modules, OBC connectors.

Industrial Robotics: Servo drive control boards, sensor fusion units.

Telecom Infrastructure: 5G mm Wave antenna arrays, base station power distribution.

Medical Devices: Patient monitor PCBs, imaging equipment back planes.

4 Reasons to Choose Us

Pin-Perfect Precision:

Patented micro-stepping control achieves 0.003mm pin spacing tolerance – 3X tighter than ISO 8092 standards.

Tooling Longevity:

Tungsten-steel progressive dies rated for 5M+ cycles (3X industry average lifespan).

Validation Excellence:

Exceeds USCAR-25 vibration specs (20G @ 500Hz) and 85°C/85% RH damp heat testing.

Plug-and-Play Integration:

Pre-crimped reel packaging compatible with JUKI/Yamaha SMT lines.

Explore advanced crimp terminal standards from IPC International Standards to understand design compliance for high-density pin layouts.