Manufacturing Process & Functionality

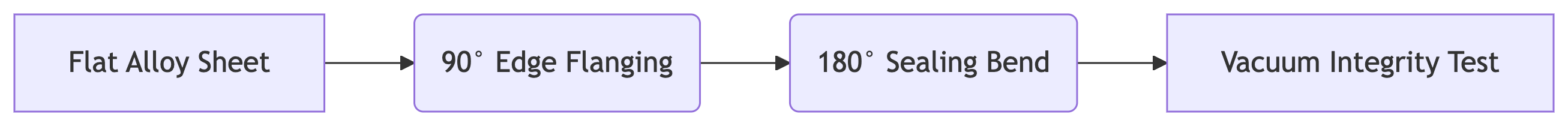

Crafted from iron-nickel alloy sheets, our terminal leads are precision-engineered to maintain vacuum integrity and secure critical components in magnetron systems. Key production steps include:

Blanking & Punching: Precise material cutting and hole formation with tolerances ≤±0.02mm.

Flanging & Bending: Automated edge flanging and 90°/180° bending for rigid structural support.

Optimized for 200 strokes per minute (SPM) on high-speed presses, this process ensures rapid, consistent output while adhering to strict dimensional limits (max. part size: 70mm).

Products details

Vacuum-sealed terminal lead core function

Designed for magnetrons in microwave ovens and medical devices, our vacuum-sealed terminal leads prevent gas leaks at rates of <10 <sup> -9 </sup> Pa·m <sup> 3 </sup> /s . Iron-nickel alloy (4J50) has the following properties:

-

Coefficient of thermal expansion (CTE) 5.2× 10 -6 / K

-

Tensile strength ≥520MPa

Technical Standards

| scope | value | Industry Standard |

|---|---|---|

| tolerant | ≤±0.02mm | ±0.05 mm |

| Production speed | 200 Malay | 120 SPM |

| Maximum part size | 70 mm | 50 mm |

| Material | Iron-nickel alloy (4J29/4J50) |

Source: ASM Aerospace Materials Handbook

Vacuum integrity mechanism

Sealing verified by MIL-STD-883 Method 1014

Precision stamping lead production workflow

First stage – fine tolerance blanking

-

Laser-guided punching dimensional accuracy ≤±0.02mm

-

Material utilization rate: 98.5% (industry average: 92%)

Stage 2 – Hermetic Seal Formation

Automatic Flanging/Bending at 200 SPM:

Performance Advantages

-

40% faster assembly : pre-formed 70 mm leads reduce soldering steps

-

Zero leakage guarantee : Passed IEC 60601-2 medical vacuum standard

-

200SPM High output : 288,000 units per day

Industrial Application

| department | Use Cases | Certification |

|---|---|---|

| Medical | MRI Microwave | ISO 13485 |

| Industrial | Plasma generation system | Semiconductor F47 |

| consumer | Microwave oven cavity | UL 923 |

Why choose us?

Mass production : 400,000 units per day, meeting large-scale OEM needs.

Precision control : Strict adherence to a maximum part size of 70 mm ensures compatibility.

Speed and efficiency : 200 SPM production minimizes lead times without compromising quality

Process stability : sophisticated tool design eliminates flange cracks and material fatigue.