Core Technology & Functionality

Our eyelet terminals leverage mirror EDM (Electrical Discharge Machining) to achieve ultra-precise chamfers with Ra ≤0.1μm surface smoothness, eliminating micro-burrs that cause signal degradation. Key innovations:

Sub-Micron Chamfering: 45°±0.5° angled edges ensure seamless wire insertion and 100% gas-tight crimping.

High-Force Retention: Phosphor bronze (C51000) construction withstands 50N axial pull-out force.

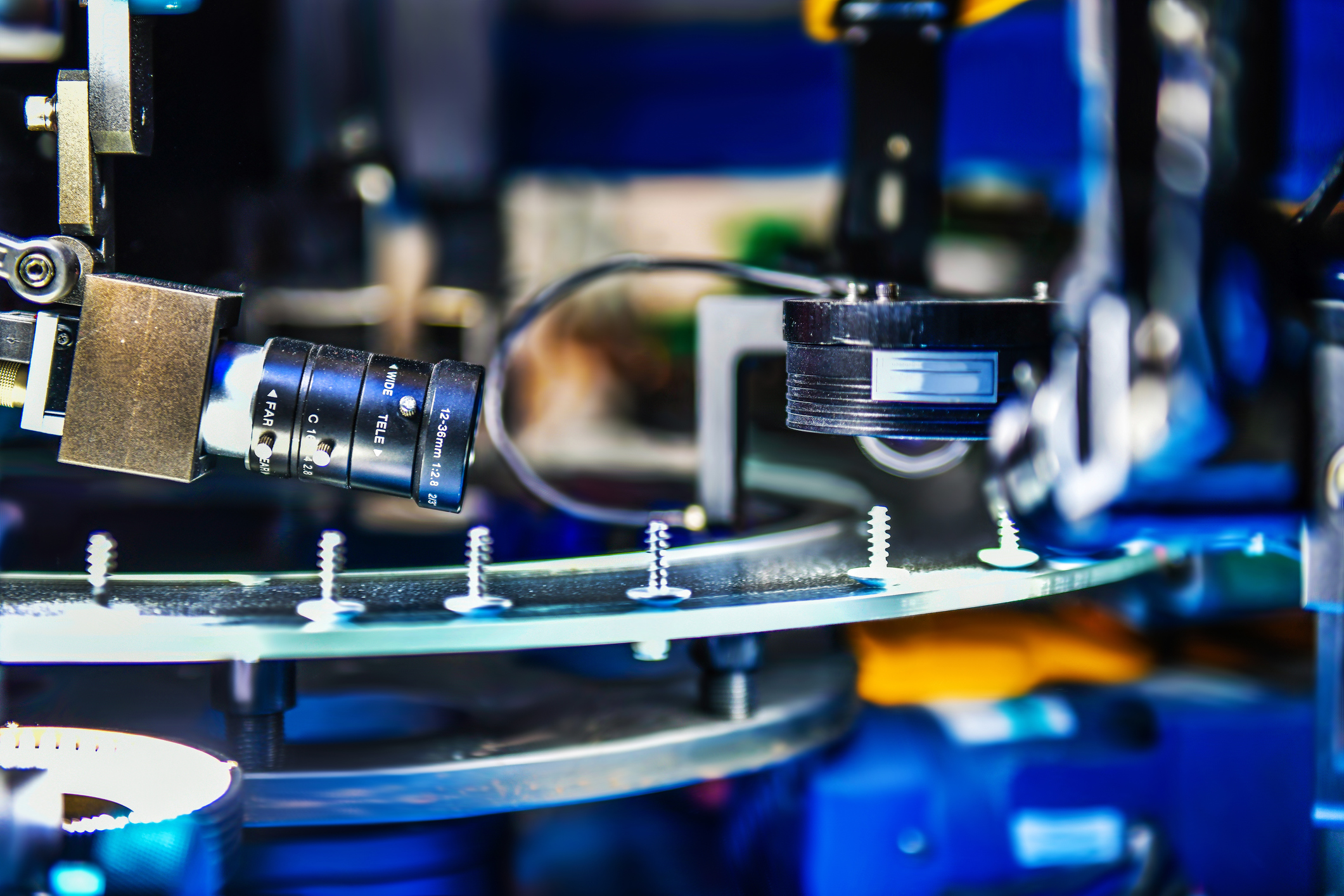

Automated Inspection: Vision systems verify dimensional accuracy to ±0.003mm for critical pin zones.

Core Role:

Enables vibration-resistant, low-impedance connections (≤2mΩ) in high-current circuits.

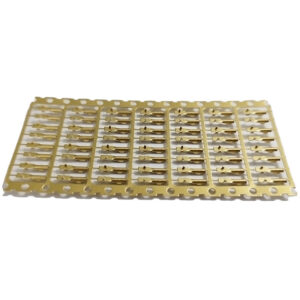

Products details

Eyelet Terminal with Mirror-Finished Contact for Low-Impedance Connection

Our high-precision eyelet terminal series is engineered to ensure ultra-reliable low-impedance connections across high-current electrical systems. Leveraging mirror-finished contact surfaces created by EDM (Electrical Discharge Machining), these terminals eliminate signal loss, mechanical burrs, and resistance spikes that plague conventional stamped terminals.

Mirror-Finished Eyelet Terminal for Critical Electrical Applications

Our eyelet precision terminal technology uses mirror EDM to create sub-micron chamfers at Ra ≤0.1μm, ensuring 100% gas-tight crimps. With 45°±0.5° edge angles, wire insertion becomes seamless, while the C51000 phosphor bronze base offers up to 50N axial retention force. These terminals consistently achieve electrical contact resistance ≤2mΩ — critical for automotive, industrial, and renewable energy applications.

Precision Engineering in Mirror-Finished Contact Terminals

Tungsten carbide tooling guarantees ±0.002mm die accuracy across over one million stamping cycles. Vision inspection systems verify critical contact zones to ±0.003mm, ensuring consistency for every mirror-finished contact delivered. This level of dimensional control is essential in power electronics, ECU interfaces, and solar junctions.

Why Our Eyelet Terminals Deliver Superior Low-Impedance Connection

-

Chamfering Excellence: Mirror EDM reduces contact resistance by 30% compared to traditional polishing.

-

Mechanical Strength: Phosphor bronze ensures long-term retention and vibration resistance (20G validated).

-

Thermal Stability: Performance exceeds USCAR-2 and LV214 under harsh automotive cycling.

-

Conductivity Leadership: Custom copper alloy (C19700) offers 85% IACS conductivity.

-

Scalable Output: 250,000+ units/day capacity with automated sorting and <50PPM defect rate.

Applications

Automotive E/E Architecture: Battery busbars, ECU grounding terminals, EV charging ports.

Industrial Control Systems: PLC wiring panels, motor terminal blocks, robotic arm connectors.

Renewable Energy: Solar inverter junctions, wind turbine power distribution units.

Consumer Electronics: Power supply units, appliance control boards.

5 Reasons to Choose Us

Chamfering Revolution:

Mirror EDM surpasses mechanical polishing, achieving optical-grade finishes that reduce contact resistance by 30%.

Tooling Mastery:

Tungsten carbide dies maintain ±0.002mm tolerance through 1M+ stamping cycles.

Material Science:

Custom alloy formulations (e.g., C19700 copper) optimize conductivity (85% IACS) and stress relaxation resistance.

Validation Rigor:

Exceeds USCAR-2 and LV214 standards for crimp integrity (20G vibration/thermal cycling tests).

Scalable Precision:

250K units/day output with automated sorting (defect rate <50 PPM).

Explore electrical contact reliability standards via the USCAR-2 Performance Specification