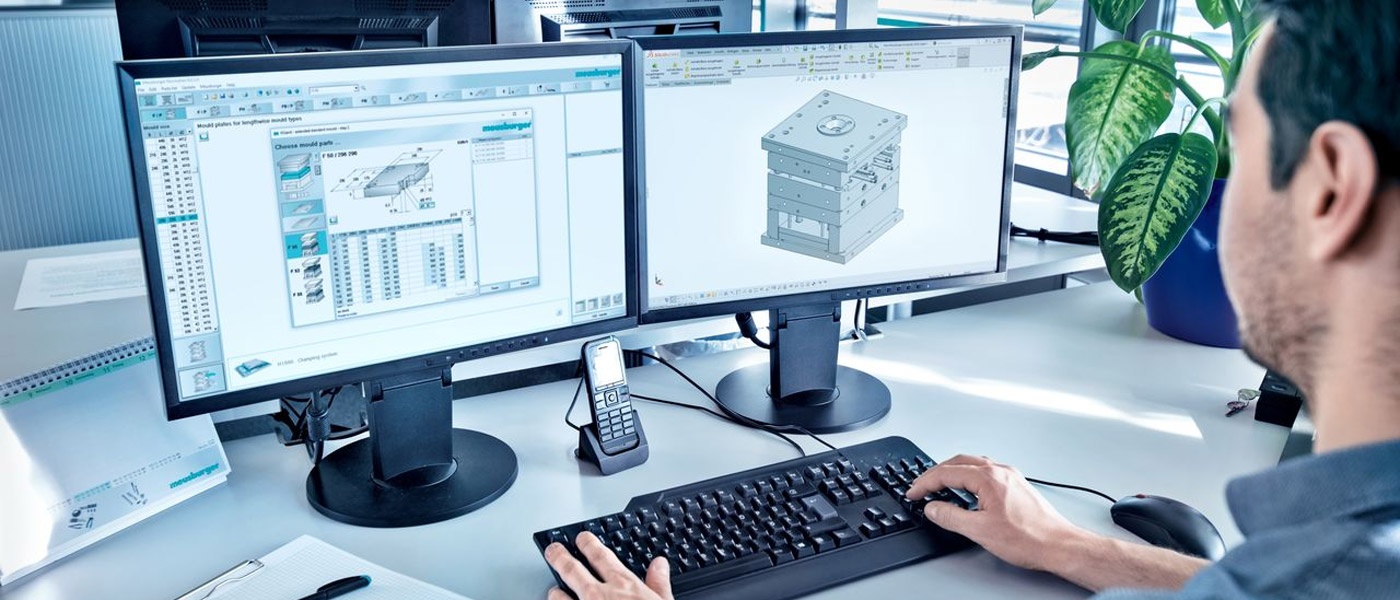

Our metal housings utilize non-thinning stretch forming with German high-lubricity oils to maintain uniform wall thickness (±0.05mm) while eliminating material weakening. Key breakthroughs:

Zero-Thinning Integrity: Preserves 100% material thickness vs. industry-standard 15-20% thinning, boosting tensile strength by 25%.

Ultra-Smooth Surfaces: German lubricants achieve Ra ≤0.4μm finishes, reducing micro-crack risks.

Tooling Longevity: Proprietary oil formulation extends die life to 1M+ cycles (3X industry average).

Core Role:

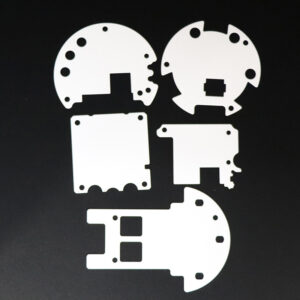

Provides EMI shielding and mechanical protection for sensitive electronics in extreme environments.

Products details

Metal Housing with Non-Thinning Stretch Forming for EMI Shielding Enclosures

Our next-generation metal housing solutions use non-thinning stretch forming technology to deliver superior structural integrity, surface perfection, and enclosure stability for high-performance electronics. Unlike traditional draw forming that thins the material by 15–20%, our method retains 100% wall thickness, boosting mechanical strength by up to 25% while reducing micro-crack risks.

EMI Shielding Metal Housing Using Non-Thinning Stretch Forming

By leveraging German-engineered high-lubricity oils and precision dies, we maintain ±0.05mm wall consistency in every EMI shielding enclosure. This ensures uniform electromagnetic protection across complex geometries like EV battery casings and motor control units. Additionally, our surface finish quality reaches Ra ≤0.4μm, eliminating the need for secondary polishing and increasing part reliability in rugged environments.

Tool Life & Cost Benefits of Non-Thinning Stretch Forming Metal Housings

Our metal housing process isn’t just about performance — it’s also about durability and cost-efficiency. The proprietary lubricant formulation extends die life beyond 1,000,000 cycles, more than three times the industry average. Over five years, this reduces tooling costs by up to 40%, making it an ideal choice for automotive OEMs and high-volume industrial applications.

Why Choose Our Metal Housing for EMI Shielding Enclosures

-

Zero-Thinning Guarantee: 100% material retention enhances tensile strength and fatigue resistance.

-

Surface Precision: German oils produce optical-grade finishes (Ra ≤0.4μm).

-

Scalable Production: Automated forming ensures consistent wall integrity at 200K+ units/month.

-

Tool Longevity: Die wear is reduced significantly, extending lifespan and cutting cost.

-

Global Compliance: Materials and processes conform to RoHS and REACH standards.

Applications of EMI Shielding Metal Housings

-

EV Platforms: Battery module enclosures and inverter shells.

-

Consumer Devices: Shielding for IoT hubs and RF-sensitive electronics.

-

Telecom Hardware: 5G small cell enclosures and edge computing casings.

-

Medical Electronics: MRI-safe enclosures and EMI-hardened control units.

Why Choose Us

Surface Perfection:

Mirror-like finishes (Ra ≤0.4μm) eliminate post-polishing costs.

Tooling Economy:

German oils reduce die wear, slashing tooling costs by 40% over 5 years.

Learn about EMI shielding standards in enclosure design via IEEE Electromagnetic Compatibility Resources