Manufacturing Process & Functionality

Our coil components are precision-engineered for reliable current conduction in magnetrons, utilizing fully automated winding and insertion processes. Key production stages include:

Automated Wire Winding: High-speed winding machines ensure uniform coil curvature and tightness (tolerance ≤±0.1mm).

Paint Stripping & Terminal Insertion: Laser-controlled paint stripping maintains consistent insulation length, while robotic insertion guarantees flat, secure terminals.

Cryogenic Cooling: Post-assembly low-temperature stabilization enhances structural integrity and electrical consistency.

Designed for 25,000 units/day output, these coils deliver unmatched stability in high-frequency environments.

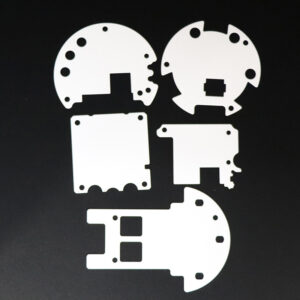

Products details

High-Performance Precision Coil Components

CoilCore Precision Windings are developed to meet the growing demand for precision coil components that offer exceptional reliability in electromagnetic applications. Leveraging automated coil winding technologies, our production line ensures tight dimensional tolerances and stable electrical performance in every unit.

These windings are engineered for use in magnetrons, microwave generators, RF amplifiers, and other high-frequency power systems where electromagnetic stability is crucial. With daily production capacity of up to 25,000 units, our solution is scalable, consistent, and optimized for global supply chain integration.

Automated Coil Winding Process

At the core of our production is a fully automated coil winding system. Using high-speed winders, the copper wire is wound with consistent curvature and compact layering, achieving a precision tolerance of ≤±0.1mm. This precision is key to delivering high-end performance in demanding electromagnetic conditions.

Automation significantly reduces human error, improves repeatability, and enhances production speed. Each coil’s geometry is continuously monitored through machine vision systems, ensuring defect-free quality control throughout the winding phase.

Laser Paint Stripping & Robotic Terminal Insertion

To maintain electromagnetic stability, the coil insulation is laser-stripped with millimeter-level control. The precision of this process eliminates the risk of overburning or underexposure, maintaining insulation integrity even after prolonged operation.

Our robotic terminal insertion process ensures flat, flush connections that reduce signal interference and power loss. Flat terminals also allow for tighter assembly tolerance in compact equipment, improving thermal dissipation and operational stability.

Cryogenic Stabilization for Electromagnetic Stability

Post-assembly, the coils undergo cryogenic treatment to stabilize their molecular structure. This step boosts the component’s resistance to thermal drift and secures long-term electromagnetic stability.

Cryogenic cooling reduces residual stress in the materials, which can be a source of unwanted resistance and magnetic field fluctuation over time. This leads to longer lifespan, lower failure rates, and superior consistency across all units, even in harsh industrial environments.

Applications

Microwave oven magnetron

Why Choose Us

Automation Excellence: Robotic winding and insertion eliminate human error, achieving 99.8% consistency.

Stability Assurance: Cryogenic treatment reduces thermal drift by 40%.

High-Yield Production: 25,000 units/day capacity with ISO 13485-compliant quality protocols.

Precision Control: In-line optical inspection validates coil spacing (≤±0.05mm) and insulation integrity.

Learn more about electromagnetic coil design standards from IEEE Standards Association