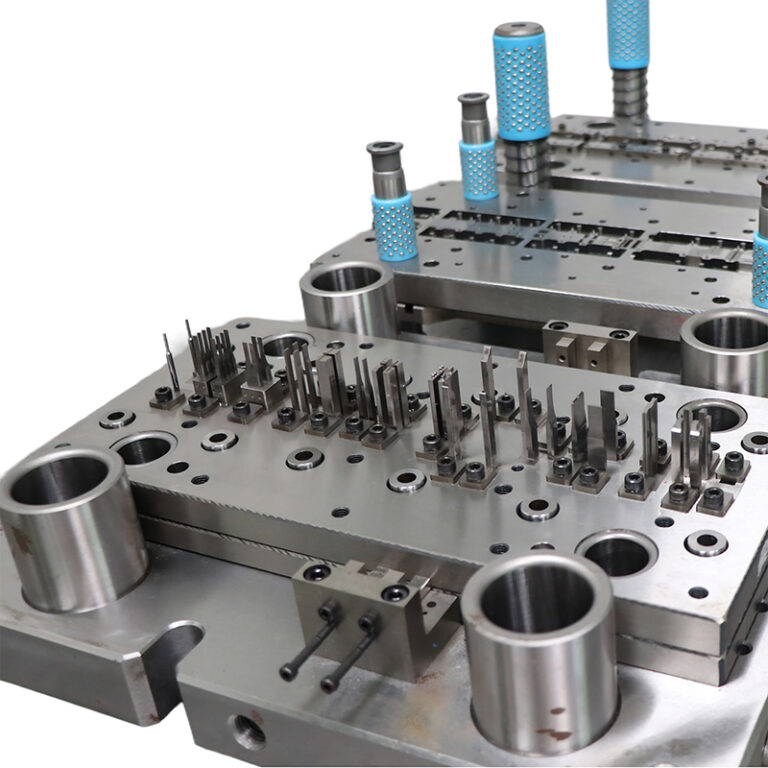

Multi-Station Progressive Stamping Dies

Our multi-station progressive dies automate cutting, punching, bending, and forming in a single pass, reducing production time and material waste. Designed for high-volume output (e.g., 20,000+ units/day) with tight tolerances (±0.01mm), these dies are ideal for complex metal components.

Key Features:

✅ Single-Side Strip Feeding – Continuous, efficient material processing.

✅ Optimized Nesting Layouts – Minimizes scrap and reduces costs.

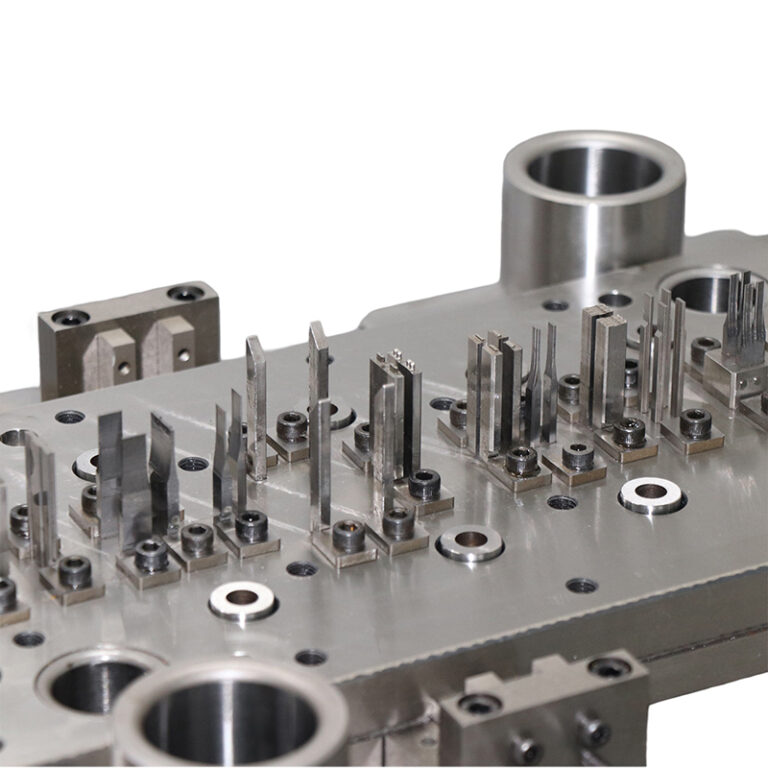

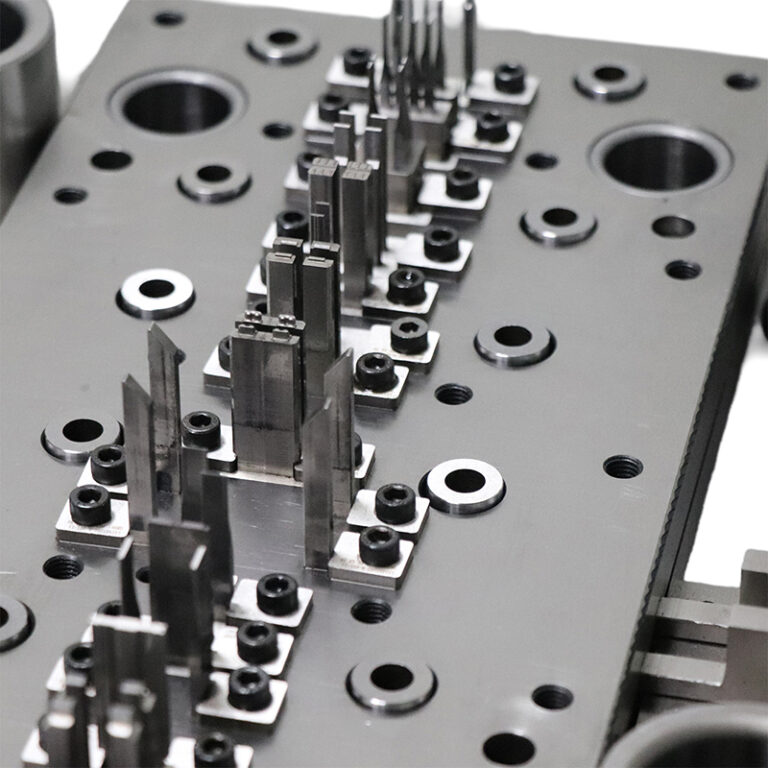

✅ Multi-Process Integration – Combines cutting, bending, and forming in one die.

Products details

Multi-Station Progressive Stamping Dies – High-Speed Precision Manufacturing

What Are Multi-Station Progressive Stamping Dies?

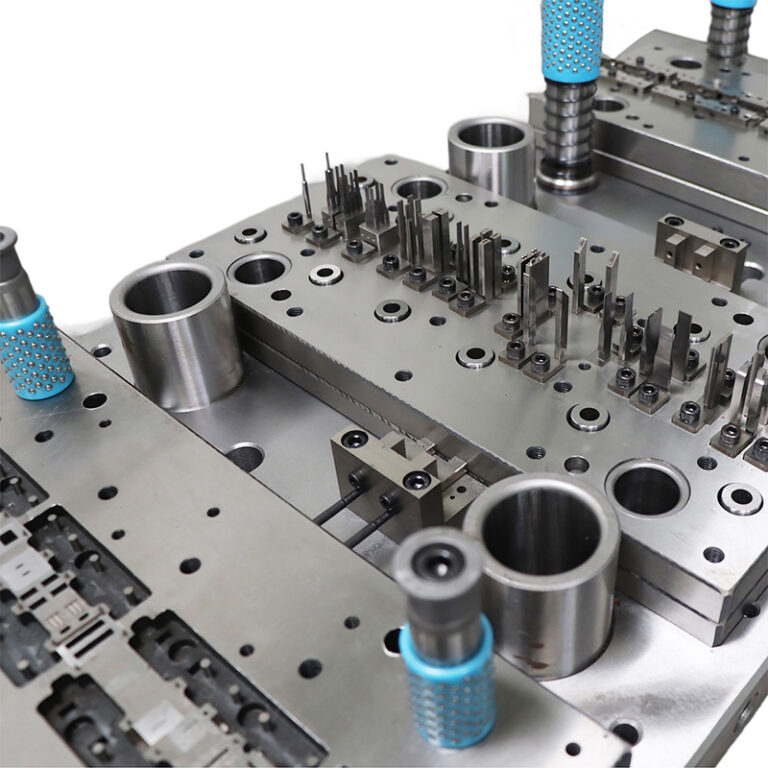

Multi-station progressive stamping dies are advanced tooling systems designed for high-volume metal component production. These dies perform multiple operations—such as cutting, punching, bending, and forming—in a continuous, automated sequence. By using a single-side strip feeding system, they maximize efficiency while minimizing material waste through optimized nesting layouts.

Industries requiring tight tolerances (±0.01mm) and rapid production (e.g., 20,000+ units/day) rely on these dies for consistent, high-quality output.

Key Advantages of Multi-Station Progressive Dies

1.High-Speed Production

Ideal for mass manufacturing, reducing cycle times and labor costs.

Capable of producing complex parts in a single pass, eliminating secondary operations.

2.Precision Engineering

Maintains ultra-tight tolerances (±0.01mm) for critical components.

Ensures uniformity across high-volume runs.

3.Material Efficiency

Optimized strip layouts minimize scrap, lowering material costs.

Suitable for stainless steel, aluminum, copper, and specialty alloys.

4.Automation Compatibility

Seamlessly integrates with robotic feeding and ejection systems for full automation.

Applications of Progressive Stamping Dies

Multi-station progressive dies are widely used in:

Automotive Components

Chassis brackets, electrical connectors, fuel system parts.

Electronics & Electrical

Shielding plates, terminal connectors, heat sinks.

Household Appliances

Structural frames, hinges, mounting plates.

Why Choose Our Progressive Stamping Solutions?

10+ Years of Expertise – Proven experience in high-speed stamping die manufacturing.

State-of-the-Art Equipment – 45+ presses (25T–300T), including 8 dedicated multi-station machines.

Strict Quality Control – 100% inspection using 2.5D CMM and optical measurement systems.

Learn more about Zhengqiang’s strength

Customized multi-station progressive stamping dies

Optimized for Performance & Durability

Our progressive stamping dies are engineered for:

Long tool life – Hardened steel components resist wear.

Low maintenance – Precision alignment reduces downtime.

Scalable production – Easily adjustable for different materials and thicknesses.

For industries demanding high-speed, precision metal stamping, our multi-station progressive dies deliver unmatched efficiency and reliability.