- Information Classification

Best Precision Metal Stamping Parts | Complete 2025 Guide

Author | Zhengqiang Industry Insights Team

Updated | December 2025

In the rapidly evolving world of modern manufacturing, best precision metal stamping parts are indispensable. These parts are essential components in the production of everything from electronics and automotive systems to medical devices and smart technology. As industries demand higher quality, durability, and cost-efficiency, precision metal stamping is becoming the go-to process for creating complex, high-performance parts. In this guide, we will explore the ins and outs of best precision metal stamping parts, focusing on their creation, applications, and key factors that define their excellence.

What Are Best Precision Metal Stamping Parts?

Best precision metal stamping parts are metal components produced through a precise stamping process that involves using custom-designed dies and high-pressure stamping presses. The result is a product with excellent dimensional accuracy, durability, and repeatability. These parts are known for their ability to be produced in large volumes, often at a significantly lower cost than traditional machining processes, making them ideal for industries requiring high-precision components at scale.

Key Features of Best Precision Metal Stamping Parts:

-

Dimensional Accuracy: High precision and repeatability, ensuring that each part meets exact specifications.

-

Cost-Effective Manufacturing: Ideal for large-volume production, minimizing material waste and labor costs.

-

Durability: Stamped parts can withstand high-stress conditions, making them ideal for demanding applications.

-

Consistency: Every part produced is identical, maintaining uniform quality throughout large production runs.

These features make best precision metal stamping parts a preferred choice for manufacturers across various industries.

How Are Best Precision Metal Stamping Parts Made?

The process of producing best precision metal stamping parts begins with selecting the right materials and designing specialized dies. The high-pressure presses shape the metal sheets into the required forms. The following steps outline the core process of precision metal stamping:

Step-by-Step Process for Producing Precision Stamped Parts

-

Material Selection:

Choosing the right material is crucial to achieving the desired properties of the stamped parts. Commonly used materials include stainless steel, aluminum, brass, and copper. Each material offers unique characteristics that make it suitable for specific applications, such as conductivity, corrosion resistance, or strength. -

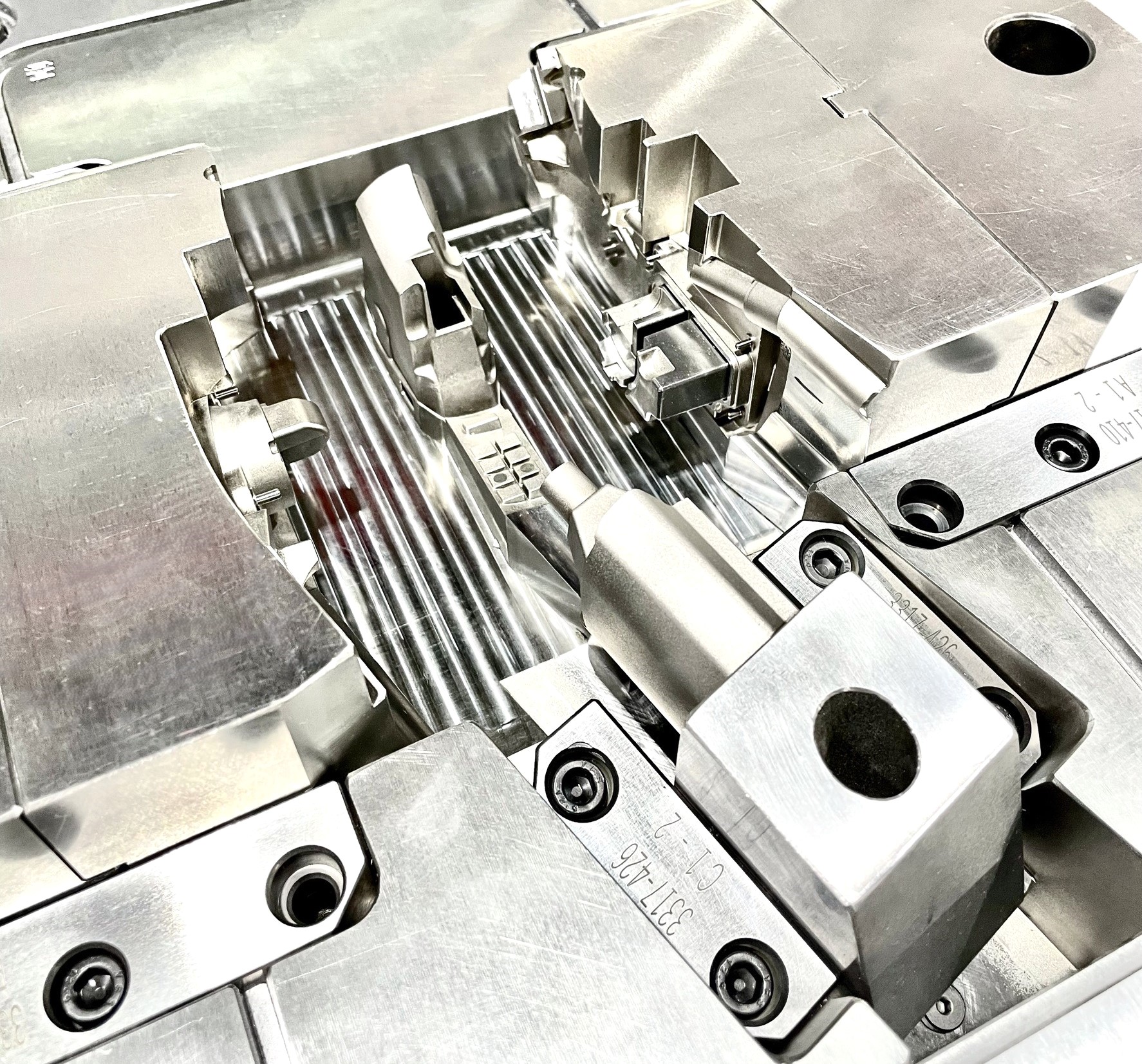

Tooling Design:

Custom-designed dies are created to match the exact dimensions and shape required for the part. Tooling is crucial for ensuring that the stamped parts meet the required tolerances and specifications. This stage involves precision engineering to account for factors like material flow and deformation during the stamping process. -

Stamping:

The stamping process itself uses a high-pressure die and punch to shape the metal sheet. This step may involve a combination of operations, including punching, bending, blanking, and drawing, depending on the complexity of the part. The dies are designed to create the desired shape with tight tolerances. -

Secondary Operations:

After the parts are stamped, additional processes may be applied. These secondary operations can include surface treatments (such as coating or plating), heat treatments to improve material properties, and trimming or cleaning to achieve the final finish. -

Inspection and Quality Control:

The final step in the process involves inspecting the parts for defects and ensuring they meet the required quality standards. This includes dimensional checks, surface inspections, and functional testing. With best precision metal stamping parts, stringent quality control is essential to ensure reliability and performance.

Industries That Benefit from Best Precision Metal Stamping Parts

Best precision metal stamping parts are versatile components used in a wide range of industries. Their ability to meet stringent performance standards and be produced at scale makes them a critical part of manufacturing operations.

Key Industries Using Precision Metal Stamping Parts:

-

Electronics:

Electronic components such as connectors, terminals, and capacitors require best precision metal stamping parts for their functionality and reliability. These parts are essential for ensuring stable connections and conductivity in devices ranging from smartphones to complex industrial machinery. -

Automotive:

The automotive industry uses precision stamped parts for components such as brackets, sensors, battery parts, and housing for critical systems. These parts must be reliable, lightweight, and durable to withstand harsh environments, including high temperatures and mechanical stress. -

Medical Devices:

Medical technology companies rely on best precision metal stamping parts to create highly accurate and safe components for devices like surgical instruments, diagnostic machines, and implantable devices. The need for precision is critical in ensuring patient safety and device performance. -

Aerospace:

The aerospace sector uses precision stamped parts for components that must meet rigorous safety and performance standards. Parts used in aircraft, satellites, and defense equipment require the highest levels of precision and material quality to perform reliably in extreme conditions. -

Industrial Equipment:

Precision stamped components are used in manufacturing machinery, robotics, and other industrial equipment. These parts are often subjected to high wear and tear and must maintain high performance over long periods of operation.

Materials Used in Best Precision Metal Stamping Parts

The choice of material is a critical factor in the quality and performance of best precision metal stamping parts. Different materials offer distinct properties that make them suitable for specific applications. The most commonly used materials include:

Common Materials for Precision Stamped Parts:

-

Stainless Steel: Known for its corrosion resistance and strength, stainless steel is often used in medical, automotive, and aerospace applications.

-

Aluminum: Lightweight and cost-effective, aluminum is commonly used for parts in electronics, automotive, and consumer goods.

-

Copper: Excellent for electrical components due to its high conductivity, copper is used in connectors and circuit board parts.

-

Brass: Brass offers excellent machinability and corrosion resistance, making it ideal for precision stamped components in various industries.

-

Nickel Alloys: These materials are used in harsh environments that require high heat and corrosion resistance, such as aerospace and military applications.

Choosing the appropriate material ensures that best precision metal stamping parts perform reliably in their respective industries.

Why Choose Zhengqiang Technology Group for Best Precision Metal Stamping Parts?

Zhengqiang Technology Group is a leading manufacturer of best precision metal stamping parts, specializing in high-quality, durable, and cost-effective solutions for industries worldwide. Our advanced manufacturing processes, expert engineers, and strict quality control standards ensure that every part we produce meets the highest industry standards.

Why Zhengqiang:

-

Expertise in Metal Stamping: With years of experience in the industry, we are well-equipped to handle a wide range of materials and complex designs.

-

High-Quality Manufacturing: We use state-of-the-art equipment to ensure that all parts meet precise specifications.

-

Global Reach: Zhengqiang serves clients worldwide, providing fast lead times and responsive customer service.

-

Cost-Effective Solutions: Our efficient processes reduce material waste and labor costs, making us a cost-effective choice for high-volume production.

FAQ: Best Precision Metal Stamping Parts

What Is Precision Metal Stamping?

Precision metal stamping is a manufacturing process where high-precision dies and presses are used to form metal sheets into detailed parts. This process ensures that each part has the exact dimensions, strength, and durability required for the application.

What Industries Benefit Most from Precision Metal Stamping?

Industries such as electronics, automotive, aerospace, medical devices, and industrial equipment rely on best precision metal stamping parts for high-performance components that need to meet strict quality standards.

Can Best Precision Metal Stamping Parts Be Customized?

Yes, we offer custom tooling and die design to meet specific requirements. Whether you need unique shapes, sizes, or materials, we can tailor the design to suit your needs.

How Do You Ensure Quality in Stamped Parts?

We use advanced quality control methods, including dimensional checks, material testing, and surface inspections, to ensure that every part we produce meets industry standards and customer requirements.

Conclusion: The Future of Best Precision Metal Stamping Parts

As industries continue to evolve, the demand for best precision metal stamping parts will only increase. By embracing technological innovations and optimizing manufacturing processes, precision metal stamping will remain a vital part of global production systems. Whether you’re in electronics, automotive, medical, or industrial sectors, partnering with a reliable manufacturer like Zhengqiang Technology Group ensures that you get high-quality, cost-effective solutions tailored to your needs.

Contact Us Today!

Looking for best precision metal stamping parts for your next project? Contact Zhengqiang Technology Group today for expert consultation, high-quality components, and reliable customer support.

📞 Reach out to us now to discuss how we can meet your manufacturing requirements!