- Information Classification

Electroplating Experiment Method | Hull Cell Technique 2025

Author | Zhengqiang Industry Insights Team

Updated | September 2025

Introduction to Electroplating Experiment Method

The Electroplating Experiment Method is an essential scientific and industrial approach used to evaluate plating performance, bath composition, and process reliability. Among the many methods available, the Hull Cell technique stands out as one of the most widely adopted tools by electroplating engineers, technicians, and quality assurance professionals. It enables a small-scale simulation of the plating process, offering quick insights into current density distribution, bath chemistry, and the overall quality of the deposited layer.

Electroplating itself plays a critical role across industries such as automotive, aerospace, electronics, and precision component manufacturing. From ensuring corrosion resistance to enhancing conductivity, a properly executed plating process can make the difference between a reliable product and a defective one. Understanding and correctly applying the Electroplating Experiment Method allows manufacturers to standardize processes, avoid costly errors, and maintain consistency in large-scale production.

In this article, we provide a detailed guide to the Hull Cell method—explaining how it works, common mistakes in execution, and how to achieve accurate, reproducible results. By doing so, companies can optimize their plating lines and meet the growing demand for high-performance coated components.

What is the Hull Cell Technique?

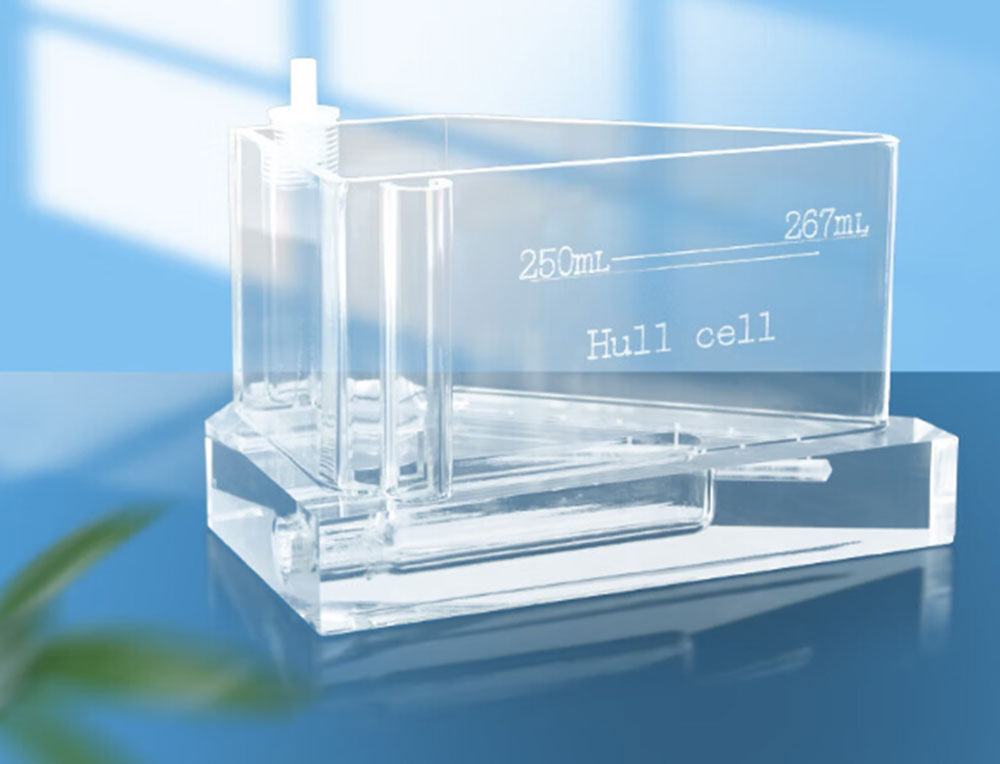

The Hull Cell, a small trapezoidal test cell, was designed specifically to evaluate the electroplating characteristics of a solution under controlled laboratory conditions. When connected to a rectifier and filled with a plating bath, it produces a current density gradient across the test panel. This unique setup enables engineers to study how different current densities affect the deposit quality on a single specimen.

By observing variations such as brightness, burning, pitting, or roughness across the Hull Cell panel, professionals can draw valuable conclusions about the condition of the plating bath. For example:

-

High current areas reveal issues like burning or poor leveling.

-

Low current density zones may show dullness, pitting, or incomplete coverage.

-

Mid-range areas often indicate whether additives and brighteners are functioning effectively.

The Hull Cell Electroplating Experiment Method is therefore an indispensable diagnostic tool. Rather than trial-and-error on large tanks—which is both expensive and time-consuming—engineers can quickly identify adjustments in solution chemistry or operating parameters by analyzing one small test panel.

Importance of Electroplating Experiment Method in Industrial Applications

For industries that rely heavily on plating, the Electroplating Experiment Method is more than just a laboratory routine; it is a cornerstone of quality assurance. Automotive manufacturers, for instance, need to ensure that engine components, fasteners, and decorative trims meet strict durability standards. In electronics, thin and uniform coatings are crucial for conductivity and performance.

Key benefits of using the Hull Cell technique include:

-

Process Optimization – Quickly determines the ideal current density ranges for specific solutions.

-

Troubleshooting – Identifies plating defects before they affect mass production.

-

Additive Evaluation – Helps assess the efficiency of brighteners, levelers, and other chemicals.

-

Quality Assurance – Ensures reproducibility and consistency of finished components.

By incorporating this Electroplating Experiment Method, companies not only reduce the risk of production errors but also build stronger trust with customers who demand reliability and excellence in every product.

Common Mistakes in Hull Cell Electroplating Experiment Method

Despite its advantages, the Hull Cell Electroplating Experiment Method can lead to misleading results if not executed properly. Several recurring mistakes occur in industrial practice, often because of negligence in standardization or lack of awareness among technicians.

1. Using Non-standard Anodes

Many experimenters substitute standard Hull Cell anodes with pieces cut directly from tank anodes. These substitutes are often thicker than recommended—sometimes exceeding 10mm. This alters the geometry of the cell and disrupts current distribution, leading to inaccurate representation of the actual plating bath. Best practice is to use standardized insoluble anodes such as stainless steel or titanium when necessary.

2. Overusing the Same Bath Sample

Standard guidelines recommend limiting each Hull Cell sample to one or two test panels. Conducting three or more consecutive tests without replenishing the bath can alter the chemistry, making results inconsistent. Some researchers attempt to run four or five plates from a single sample, which compromises accuracy due to gradual depletion of additives and changes in concentration.

3. Incomplete Documentation of Conditions

For experimental results to be meaningful, operating conditions must be recorded thoroughly—temperature, bath composition, agitation method, and current density settings. Many reports omit crucial details, making comparison with other studies unreliable. Without complete documentation, even correct results lose their value in industrial decision-making.

4. Using Non-standard Hull Cells or Power Sources

Another common error involves poorly manufactured Hull Cells—either handmade or purchased from low-quality suppliers. Incorrect dimensions or poor assembly can distort current density gradients. Similarly, the use of unstable or inconsistent power supplies introduces variables that can alter deposition quality. Always specify the type of rectifier used (e.g., full-wave vs. half-wave, with or without filtering) to ensure transparency and repeatability.

By avoiding these pitfalls, companies can ensure that the Electroplating Experiment Method provides meaningful, reproducible insights.

Best Practices for Accurate Electroplating Experiment Method

To maximize the effectiveness of the Hull Cell technique, engineers must adopt a disciplined and standardized approach. Below are key recommendations for accurate execution:

-

Surface Preparation – Clean the test panel thoroughly using solvents, alkaline cleaners, or acid dips to remove oils, oxides, and contaminants.

-

Controlled Conditions – Always maintain consistent bath temperature, pH, and agitation throughout the test.

-

Standardized Equipment – Use Hull Cells that meet dimensional requirements and reliable DC power supplies with stable current outputs.

-

Precise Documentation – Record all operating parameters and include them in technical reports for future reference and comparison.

-

Regular Calibration – Periodically validate rectifiers, Hull Cell dimensions, and reference anodes to ensure consistency.

By following these practices, the Electroplating Experiment Method becomes a powerful predictive tool, helping manufacturers fine-tune processes and prevent defects before scaling to full production.

Why Choose Zhengqiang Technology Group

At Zhengqiang Technology Group, we understand the critical role the Electroplating Experiment Method plays in delivering superior products to clients across industries. With decades of expertise in precision stamping, electroplating, and advanced material processing, we have developed a systematic approach to quality control.

Our in-house laboratories are fully equipped with standardized Hull Cell systems, rectifiers, and surface treatment facilities. Every plating bath is rigorously tested using the Electroplating Experiment Method before being scaled to production. This ensures that components used in automotive engines, electronic devices, and industrial equipment meet the highest performance standards.

By choosing Zhengqiang, clients gain a trusted partner that combines scientific rigor with manufacturing excellence. We deliver not only products but also confidence, consistency, and long-term reliability.

Conclusion

The Electroplating Experiment Method, particularly the Hull Cell technique, is an invaluable tool for modern plating operations. By enabling fast and reliable evaluation of bath performance, it helps industries maintain quality, troubleshoot issues, and optimize processes with minimal risk.

Zhengqiang Technology Group leverages this method as a core part of its quality assurance strategy, delivering trusted results to clients worldwide. If you are looking for a partner that combines advanced technology with proven expertise,Contact Zhengqiang today to discuss your electroplating needs.

FAQ on Electroplating Experiment Method

Q1: What is the purpose of the Electroplating Experiment Method?

A1: It evaluates plating bath performance, identifies defects, and determines optimal current density ranges for consistent and high-quality electroplating.

Q2: How often should Hull Cell tests be conducted?

A2: Frequency depends on production scale, but many manufacturers perform tests daily or weekly to ensure bath stability.

Q3: What materials are suitable for Hull Cell test panels?

A3: Commonly used materials include steel, brass, or copper panels depending on the intended plating application.

Q4: Can Hull Cell results be directly applied to large-scale tanks?

A4: While Hull Cell results provide critical insights, scaling requires adjustment. The method highlights trends but must be validated under production conditions.

Q5: What makes Zhengqiang Technology Group a reliable partner?

A5: Our strict adherence to standardized Electroplating Experiment Method, advanced testing infrastructure, and industry experience ensure accurate results and superior product quality.