- Information Classification

Ev charging socket solutions for reliable fast charging

Powering the Future: Why EV Charging Socket Technology Matters

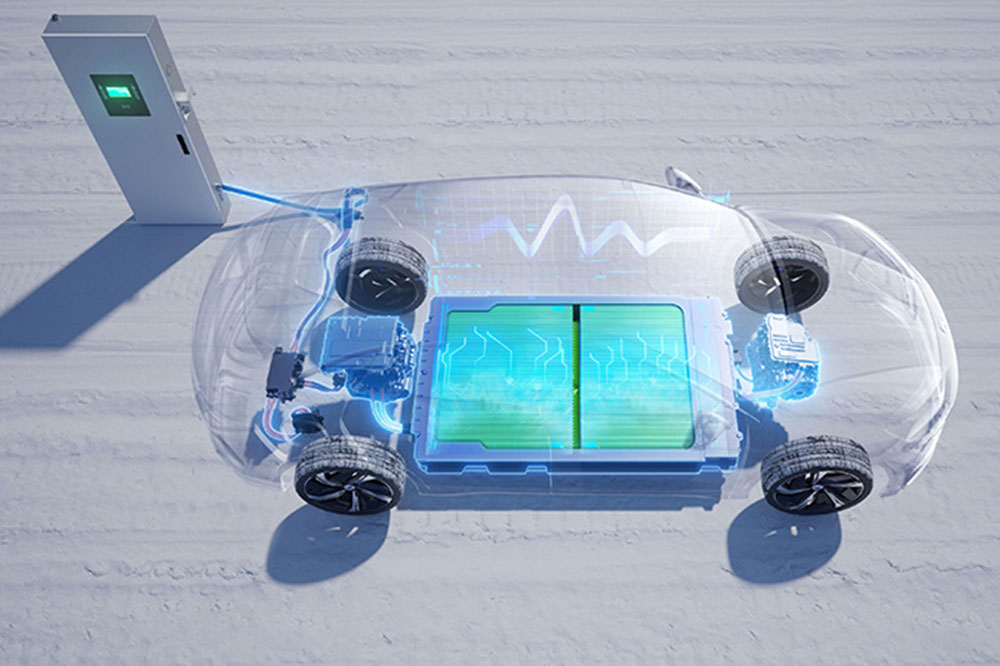

As the demand for electric vehicles (EVs) continues to surge globally, infrastructure must keep pace. The cornerstone of that infrastructure is the EV charging socket, the essential interface that ensures safe, fast, and reliable energy transfer from charging stations to vehicles. An advanced EV charging socket is not just a plug—it is a complex integration of mechanical precision, electrical efficiency, thermal stability, and environmental durability. As countries move toward electrification, the focus on developing high-performance EV charging sockets has never been greater.

In this article, we explore the technology breakthroughs and manufacturing excellence behind the EV charging socket, with a focus on how Zhengqiang Technology Group is pioneering advanced solutions to drive efficiency, reliability, and mass adoption across the EV industry. As part of a global sustainability shift, it’s crucial to understand how these sockets impact not just charging infrastructure, but also environmental goals and user convenience. From material science to user experience, every aspect matters when creating sockets that are robust and future-ready.

EV Charging Socket: Technical Breakthroughs in Material and Design

The evolution of the EV charging socket hinges on continuous material innovation and structural optimization. These sockets are exposed to repeated insertion and removal, high current flow, and varying environmental conditions. To withstand such stresses, Zhengqiang Technology Group leverages high-performance materials such as flame-retardant thermoplastics, heat-resistant ceramics, and conductive copper alloys. Our sockets are engineered to perform under ultra-high temperature and voltage ranges, with anti-oxidation coatings that ensure long-term stability.

Key innovations include:

- Multi-point Contact Design: Enhances current stability and reduces energy loss.

- Thermal Management Structures: Improves heat dissipation and socket lifespan.

- Smart Locking Mechanisms: Ensures safety and prevents unintentional disconnection during charging.

By embedding these design strategies, we create EV charging socket that are durable, safe, and efficient for both home and commercial applications. These designs undergo rigorous lab and field testing to simulate extreme use cases, ensuring performance in a variety of global climates and grid conditions. The result is a robust interface capable of supporting the long-term demands of the fast-growing EV sector.

Addressing the Infrastructure Imbalance: The Role of EV Charging Sockets

The rapid growth of electric vehicles is not without its challenges. Although over 5 million charging stations exist globally, the development is uneven—private chargers dominate the market, while public charging points remain underdeveloped. A staggering 8:1 vehicle-to-public-charger ratio underscores this imbalance, creating widespread anxiety among EV users.

EV charging socket play a pivotal role in reducing this imbalance. Zhengqiang’s modular socket systems support both slow and fast charging needs. Our engineers collaborate with urban planning departments and utility providers to ensure compatibility and scalability in densely populated urban zones.

Additionally, our smart socket solutions integrate with IoT platforms to allow real-time monitoring, load balancing, and predictive maintenance, effectively extending charger lifespan and ensuring uninterrupted operation. By improving accessibility and adaptability, Zhengqiang helps ensure that charging infrastructure can evolve in tandem with urban and rural EV expansion goals, minimizing the digital divide between regions.

Overcoming Technological Barriers with Collaborative R&D

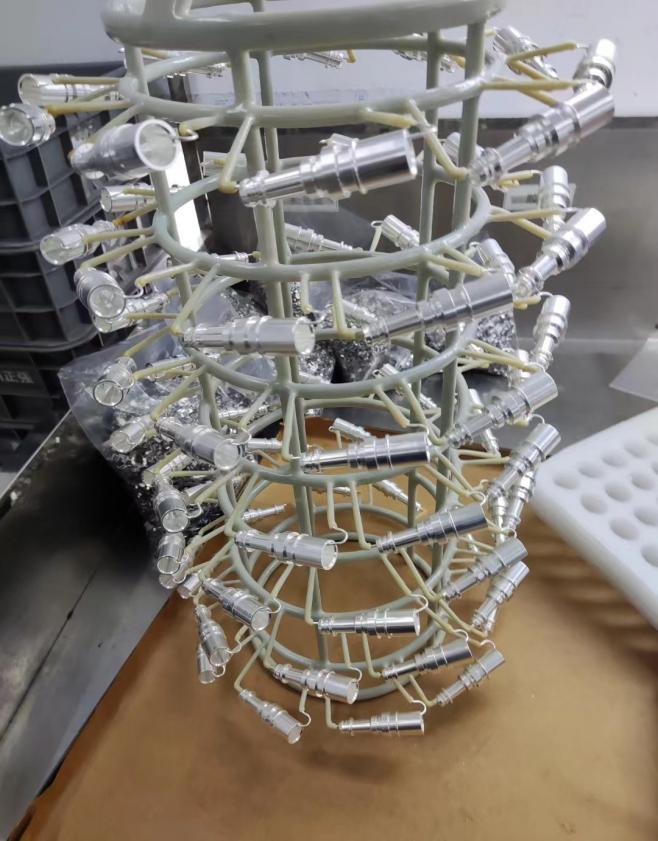

At Zhengqiang, we recognize that solving the energy replenishment challenge requires synergy across the entire supply chain. That’s why we’ve partnered with plating companies and charger OEMs to develop next-generation EV charging socket solutions. These partnerships have accelerated the commercialization of high-conductivity, corrosion-resistant connectors and reduced the lead time in bringing new designs to market.

Our R&D initiatives focus on:

- High-current endurance testing

- Corrosion resistance in humid or coastal environments

- Electromagnetic shielding to prevent interference

- Rapid manufacturing methods like CNC milling and multi-cavity molding

Such technical advancements ensure that Zhengqiang’s EV charging sockets meet the rigorous standards required for tomorrow’s smart cities and green transportation systems. Innovation is central to our mission—by fostering open communication with clients and partners, we anticipate emerging needs and integrate agile solutions that perform at scale.

Scaling EV Charging Infrastructure with Advanced Socket Systems

The EV charging ecosystem is only as strong as its weakest link. Poor socket performance can lead to overheating, arcing, and even dangerous short circuits. Zhengqiang’s EV charging sockets feature built-in safety mechanisms, including temperature sensors, ground-fault detection, and emergency shut-off systems.

With a focus on scalability, our socket platforms support:

- Fast DC charging up to 350 kW

- Interoperability with CCS, CHAdeMO, and GB/T protocols

- Customizable plug heads for regional markets

We also offer socket-integrated charging modules for OEMs seeking to embed functionality within compact form factors. Whether you’re building for residential, fleet, or highway corridor applications, our solutions meet the demand. Through intelligent modular design, our platforms also allow easier upgrades and faster deployment in infrastructure projects of varying sizes and budgets.

Why Choose Zhengqiang Technology Group?

Zhengqiang Technology Group stands at the forefront of EV charging socket innovation. With decades of experience in component processing, smart equipment development, and electronic systems integration, our approach combines industry know-how with a relentless pursuit of quality and precision.

Why customers trust us:

- Vertical Integration: From material selection to final assembly, every step is quality-controlled.

- Global Reach: Export-ready production lines meet international compliance standards.

- Customization Expertise: Tailored socket designs for diverse client needs.

- After-Sales Support: Dedicated engineers for technical consultation and maintenance support.

When you work with Zhengqiang, you gain a technology partner committed to powering the EV future. Our customer-centric development model ensures that all products are aligned with client goals, compliance mandates, and environmental regulations, maximizing both efficiency and customer satisfaction.

Conclusion: Future-Proof Your EV Infrastructure

The shift to electrified transportation requires more than just energy—it needs infrastructure that’s intelligent, durable, and safe. High-performance EV charging sockets are essential to this transition. Zhengqiang’s advanced socket technologies, tested and refined through years of R&D, ensure secure and fast energy delivery, even under the most demanding conditions.

Future-proof your EV infrastructure by partnering with Zhengqiang today. Let’s accelerate the world’s shift to electric mobility—together. With the right charging socket technology, cities can reduce emissions, individuals can drive confidently, and manufacturers can streamline their offerings. The future is electric, and it’s closer than you think.

📩 Ready to Upgrade Your Charging Hardware?

Contact Zhengqiang Technology Group now to request samples, get a quote, or speak with our engineering team. Let’s build the future of charging—starting today.

Frequently Asked Questions (FAQ)

Q1: What makes Zhengqiang’s EV charging sockets different?

A1: Our sockets use high-grade materials and advanced heat dissipation technology, offering long life, safety, and high-speed charging capability. We also provide real-world testing environments to ensure performance under diverse and demanding conditions.

Q2: Do your sockets support fast charging standards like CCS or GB/T?

A2: Yes, we offer compatibility with CCS, CHAdeMO, and GB/T standards, with customization available per client. Our engineers work with you to ensure protocol compliance, electrical safety, and optimized current handling for your target market.

Q3: Can I request a custom EV charging socket design?

A3: Absolutely. We offer design customization for cable length, current rating, plug shape, and environmental protections. We also support design iterations and prototyping to help you refine the ideal solution before mass production.

Q4: What is your production lead time?

A4: Typical production cycles range from 2–4 weeks depending on order complexity and volume. We maintain agile manufacturing capacity to meet urgent requirements when needed.

Q5: Do you ship internationally?

A5: Yes, our production and logistics systems are optimized for global distribution. We comply with regional import/export standards and provide multilingual technical documentation for global clients.