- Information Classification

Brushed Motor Brushes: Overcoming Setbacks in 2025

Author | Zhengqiang Industry Insights Team

Updated | December 2025

Introduction: The Evolution of Brushed Motor Brushes and Why It Matters

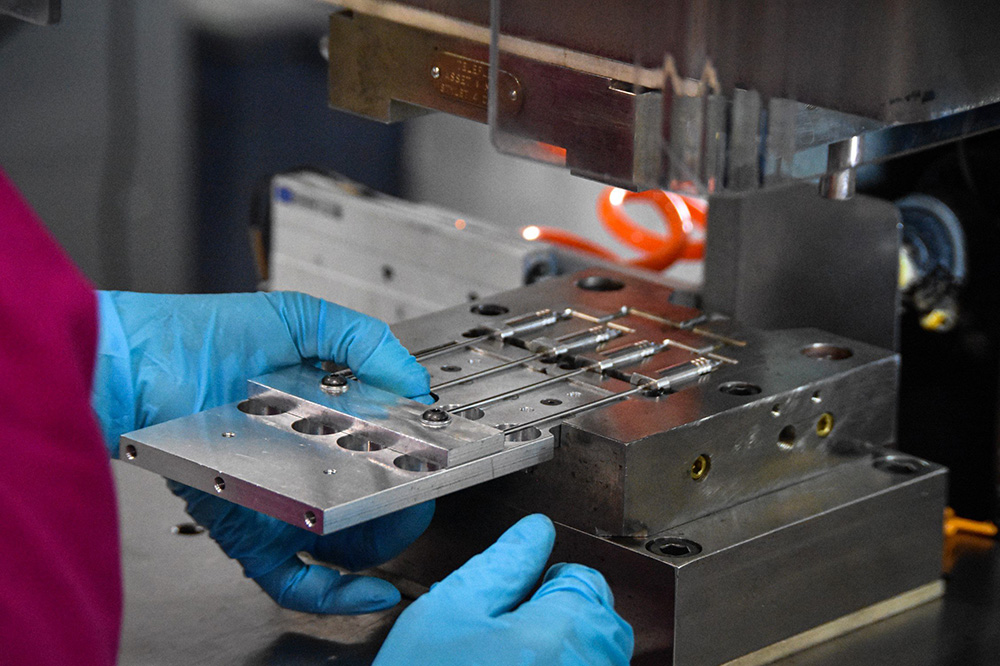

Brushed motor brushes have long been a critical component in the performance and longevity of electric motors across industries. However, as technology advances and industries demand higher efficiency, innovation in brushed motor brushes has become crucial. From materials to design, Commutator brushes are evolving rapidly, offering enhanced performance, longer life spans, and lower maintenance costs.

In this article, we will explore the trends and innovations surrounding Commutator brushes as we look towards 2025 and beyond. We’ll examine the latest advancements, the growing demand for energy efficiency, and how manufacturers are adapting to new technological challenges. Whether you’re sourcing brushes for industrial applications, power tools, or electric vehicles (EVs), understanding these trends will help you stay ahead of the curve.

The Materials Revolution: How New Materials Are Shaping Brushed Motor Brushes

1. The Shift Towards Advanced Carbon Composites

One of the most significant innovations in the brushed motor brush industry is the shift toward advanced carbon composites. Carbon brushes, which have been the standard for decades, are now being enhanced with high-performance materials like graphite and copper-infused composites. These materials provide better conductivity, durability, and resistance to wear and tear.

-

Why It Matters: This shift increases the lifespan of Commutator brushes and minimizes the frequency of replacement, which is crucial for industries relying on continuous operations, such as automotive and manufacturing.

-

What You Need to Know: Advanced composites offer more reliable performance at higher speeds and with greater efficiency, addressing issues such as heat buildup, which can compromise motor performance over time.

2. Eco-Friendly Materials and Sustainability in Brush Manufacturing

As industries focus on sustainability, manufacturers of brushed motor brushes are exploring environmentally friendly materials. Manufacturers are moving toward renewable or recyclable materials to reduce their carbon footprint and meet increasingly stringent environmental regulations. The use of greener materials is especially crucial as electric vehicle production ramps up.

-

Why It Matters: Using sustainable materials reduces the environmental impact of motor manufacturing and makes motors more eco-friendly, aligning with the goals of sustainability-conscious businesses.

-

What You Need to Know: Look for suppliers who emphasize sustainable sourcing and have certifications for environmentally friendly materials, such as REACH or RoHS compliance.

Technological Advancements: How Digital Integration is Enhancing Brushed Motor Brushes

Smart Brushes and IoT Integration

In 2025, brushed motor brushes will integrate with digital technologies like the Internet of Things (IoT). Smart brushes equipped with sensors can provide real-time data on motor performance, brush wear, and other critical parameters. This data helps predict when maintenance is needed, reducing downtime and preventing unexpected failures.

-

Why It Matters: IoT integration offers greater control and efficiency, allowing for predictive maintenance and reduced operational disruptions. Industries that rely on precision, such as robotics and aerospace, benefit greatly from these advancements.

-

What You Need to Know: As IoT technology becomes more integrated into brushed motors, ensure your supplier offers products that are compatible with your existing monitoring systems.

4. Advanced Brush Designs for Increased Efficiency

Innovations in the design of brushed motor brushes focus on improving motor efficiency. Brush shapes and configurations are evolving to optimize the contact surface area with the commutator, which reduces friction and heat buildup. These advancements result in less energy loss and smoother motor operation, which are critical for applications where efficiency and longevity are key, such as electric vehicles and renewable energy technologies.

-

Why It Matters: More efficient brushes directly translate to energy savings and lower operational costs. For businesses focused on reducing overheads, these innovations are essential.

-

What You Need to Know: Ask suppliers about new brush design options that are tailored for energy efficiency and longevity in your specific industry.

Impact on Different Industries: How Brushed Motor Brushes Are Evolving Across Sectors

5. Brushed Motor Brushes in the Electric Vehicle Market

The rise of electric vehicles (EVs) is driving demand for high-performance brushed motor brushes. EV manufacturers are looking for brushes that can handle high currents and provide superior wear resistance, as well as those that help reduce the overall weight of the vehicle to increase battery efficiency. As the automotive industry pivots to electric, brushed motor brushes are evolving to meet these new challenges.

-

Why It Matters: Brushed motor brushes are key components in EV motors, and improved performance translates to better vehicle efficiency, driving down operational costs for manufacturers and improving consumer satisfaction.

-

What You Need to Know: When selecting brushed motor brushes for electric vehicles, focus on those designed for high-efficiency motors and capable of handling the unique demands of EVs.

6. Brushed Motor Brushes for Power Tools and Home Appliances

Another growing sector is power tools and home appliances. These industries require brushed motor brushes that provide excellent durability, reduce maintenance frequency, and ensure smooth operation under heavy loads. Innovations in this area focus on reducing friction and improving the longevity of the brushes in high-performance tools.

-

Why It Matters: Long-lasting, efficient brushes reduce the need for frequent replacements and repairs, saving costs for manufacturers and end-users.

-

What You Need to Know: Look for suppliers that offer specialized brushed motor brushes designed for high-performance power tools or consumer appliances, as these sectors require robustness and reliability.

Why Choose Zhengqiang Technology Group for Your Brushed Motor Brushes Needs?

Zhengqiang Technology Group is a trusted leader in the development, manufacturing, and global distribution of high-performance brushed motor brushes. Here’s why you should partner with us for all your brushed motor brush needs:

-

Expertise and Innovation: We stay ahead of industry trends and leverage cutting-edge technologies to produce brushed motor brushes that offer superior performance and durability.

-

Customization and Precision: Our brushes are designed to meet the exact specifications of your applications, whether for industrial, automotive, or consumer products.

-

Global Support: With a vast distribution network and customer service team, we provide timely delivery and expert support wherever you are.

-

Sustainability Commitment: We prioritize eco-friendly materials and sustainable manufacturing practices, ensuring that your products meet modern environmental standards.

By choosing Zhengqiang Technology Group, you gain a reliable partner dedicated to helping you improve motor performance and reduce maintenance costs.

FAQ – Brushed Motor Brushes

Q1: What materials are commonly used in brushed motor brushes?

A1: Common materials include carbon, graphite, and copper-infused composites. New materials, such as eco-friendly composites, are also gaining popularity for sustainability and performance.

Q2: How do smart brushed motor brushes work?

A2: Smart brushes are equipped with sensors that monitor performance parameters like wear and temperature. This data helps predict when maintenance is needed, preventing unexpected motor failures.

Q3: What are the advantages of using brushed motor brushes in electric vehicles?

A3: Brushed motor brushes offer high current handling and excellent wear resistance, making them ideal for EV applications where efficiency and durability are crucial.

Q4: Can I use brushed motor brushes for power tools?

A4: Yes, brushed motor brushes are commonly used in power tools and home appliances because they provide durability, reduced friction, and long service life in high-demand environments.

Conclusion: The Future of Brushed Motor Brushes in 2025 and Beyond

While brushed motor brushes continue to play a crucial role in many industries, the future presents both exciting innovations and significant challenges. As we move into 2025, manufacturers must navigate the complexities of advanced materials, smart technologies, and industry-specific requirements. However, with the right partner, businesses can take advantage of these innovations to improve motor performance, reduce costs, and meet sustainability goals.

If you’re looking for high-quality brushed motor brushes that are built for the future, contact Zhengqiang Technology Group today. Our team of experts is ready to help you choose the perfect solution for your needs, whether you’re in the automotive, industrial, or consumer electronics sectors.

Get in touch with us now to learn more about how our advanced brushed motor brushes can enhance your business operations.