- Information Classification

Metal Stamping Dies Precision | High-Volume Tooling

Introduction

In the fast-paced world of industrial manufacturing, metal stamping dies stand at the heart of efficient, high-volume production. From automotive components and consumer electronics housings to precision brackets, connectors, and intricate hardware, metal stamping transforms flat metal sheets into complex, finished parts with exceptional accuracy and repeatability. Leveraging metal stamping dies, Zhengqiang Group delivers not only tailored die designs but also robust manufacturing processes that guarantee dimensional consistency, waste reduction, optimized material usage, and accelerated production cycles.

As global demand for lightweight, high-strength metal parts continues to surge, manufacturers face increasing pressure to maintain tight tolerances, reduce cycle times, and minimize production costs. Recognizing these challenges, Zhengqiang Group integrates advanced simulation tools, precision machining technologies, and stringent quality control measures to produce metal stamping dies that excel under the most demanding conditions. This article explores the fundamentals of stamping dies, highlights their core advantages, outlines key design and manufacturing innovations, and showcases their diverse applications across industries—equipping you with the insights needed to select the ideal stamping solution for your next manufacturing project.

Understanding Metal Stamping Dies

What Are Metal Stamping Dies?

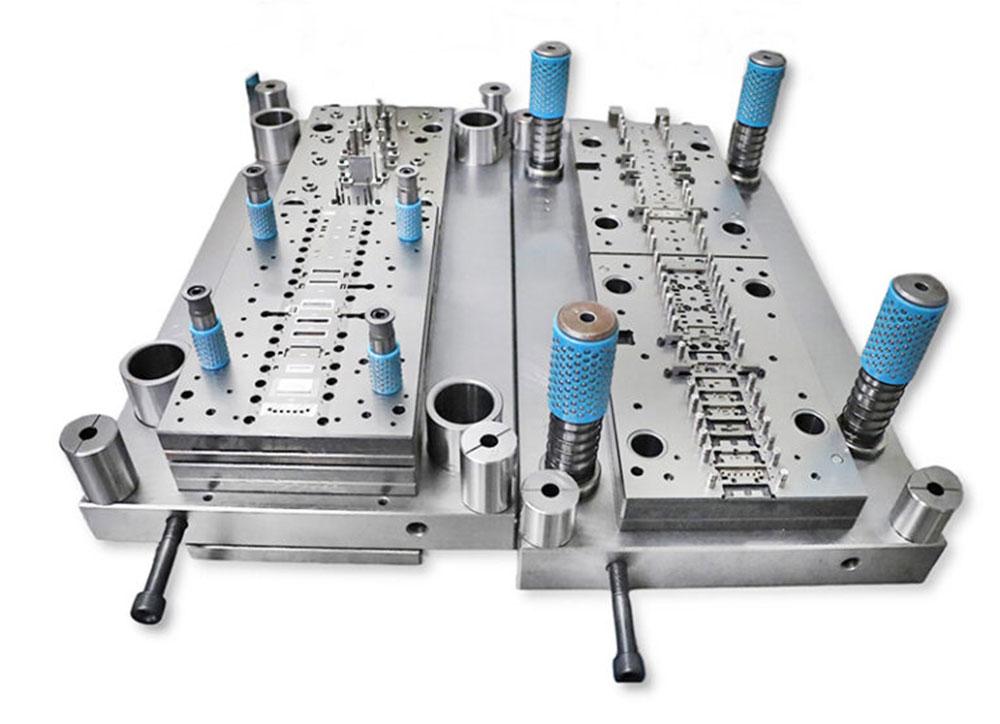

Metal stamping dies are precision-engineered tools utilized in stamping presses to cut, form, bend, or draw flat metal sheets into desired shapes at high speeds. Each stamping die assembly includes an upper die (punch) and a lower die (die block), which work in unison under controlled pressure to manipulate metal feedstock. These dies come in several configurations based on production requirements and part complexity:

- Progressive Dies: Incorporate multiple stations on a single die, performing sequential operations—blanking, piercing, forming, and trimming—in one pass, boosting throughput and reducing handling.

- Transfer Dies: Employ automated transfer systems to move workpieces between stations, ideal for multi-stage forming of complex geometries while maintaining precise alignment.

- Compound Dies: Combine cutting and forming functions within the same stroke, allowing intricate shapes and features to be created simultaneously without stock handling.

- Single-Station Dies: Operate one forming or cutting step per stroke, suitable for simpler parts or small-batch production where tool simplicity and flexibility are paramount.

By selecting the appropriate die type and optimizing die set configurations, manufacturers achieve consistent part quality, intricate feature detail, and high repeatability—even during millions of cycles. Advanced die materials, coatings, and heat treatments further enhance tool life and performance, ensuring each die delivers maximum value over its service lifespan.

Core Advantages of Metal Stamping Dies

- High Production Efficiency

- Automated stamping lines can exceed several hundred parts per minute, dramatically reducing cycle times compared to alternative processes.

- Rapid die changeover systems and quick-release mechanisms minimize downtime during maintenance or tool swaps, enabling production flexibility.

- Integration with automated material handling and inspection systems streamlines workflow and lowers labor costs.

- Dimensional Precision

- Tolerance control as tight as ±0.02 mm allows for seamless assembly in multi-component systems, enhancing end-product reliability.

- Consistent part geometry across extended runs slashes scrap rates and simplifies downstream finishing operations.

- Fine-feature capability—slots, dimples, and flanges—supports component miniaturization in electronics and automotive sensor applications.

- Material Utilization

- Advanced blank nesting and strip layout techniques achieve material yields exceeding 90%, reducing raw material waste and lowering scrap disposal expenses.

- Precise blanking and trimming produce minimal burrs, decreasing the need for secondary deburring and surface finishing.

- Cold stamping preserves base material properties without heating, maintaining mechanical performance and preventing microstructural damage.

- Cost Effectiveness

- High-volume amortization of initial die investment delivers low per-part costs, making stamping competitively economical for large batch production.

- Energy-efficient cold stamping processes eliminate the energy input required for forging or casting, reducing operational expenses.

- Die durability and optimized maintenance protocols extend service life, further lowering total cost of ownership.

Collectively, these benefits make metal stamping dies indispensable for industries demanding both high-volume output and rigorous quality standards.

The Metal Stamping Die Design Process

Initial Feasibility and Design Concept

The foundational stage of metal stamping dies creation begins with a meticulous feasibility study conducted by Zhengqiang’s experienced engineering team. During this phase, engineers assess:

- Material Characteristics: Evaluation of metal grade, thickness, tensile strength, yield strength, elongation, and surface finish requirements to anticipate formability constraints.

- Part Geometry: Detailed analysis of part complexity, feature depth, bend radii, embossing, and cross-sectional variations to determine the number of die operations needed.

- Production Volume: Forecasting annual batch sizes and lifetime cycle counts to guide die type selection—progressive, transfer, or single-station—to balance longevity with cost.

- Tolerance and Quality: Defining critical-to-quality dimensions and surface finish specifications, aligning them with stamping process capabilities.

Utilizing 3D CAD modeling integrated with finite element analysis (FEA), the design team simulates stamping operations, material flow, and stress distribution. Potential issues like springback, wrinkling, cracking, or excessive thinning are predicted and mitigated virtually. This upfront virtual validation not only reduces rework and tooling iterations but also accelerates time-to-market by ensuring metal stamping dies meet or exceed performance expectations from the very first production run.

Die Layout and Tool Path Optimization

Efficient strip layout and tool path planning are crucial to maximizing productivity and minimizing waste in metal stamping dies design. Key considerations in this phase include:

- Station Count Optimization: Determining the ideal number of forming, piercing, and trimming stations to maintain part integrity while reducing press stroke requirements.

- Blank Shape Nesting: Employing nesting software to arrange blank cut contours with minimal sheet scrap—often exceeding 90% material utilization.

- Strip Layout Engineering: Designing carrier strips, feed holes, and pilot locations to ensure smooth, jam-free material progression and precise indexing.

- Punch & Die Sequencing: Strategically ordering operations—pilot hole creation, bending, coin curl, and trim cuts—to distribute forming loads evenly and prevent cumulative stress.

Zhengqiang’s advanced nesting algorithms and process simulation tools optimize each blank pattern and tool path, ensuring that metal stamping dies achieve optimal throughput, minimal material waste, and reliable part quality throughout extended production cycles.

Advanced Manufacturing Techniques for Metal Stamping Dies

Precision Machining and EDM

Realizing the high precision and complex geometries required by metal stamping dies demands cutting-edge manufacturing methods. Zhengqiang employs:

- High-Speed CNC Milling: Delivers complex surface geometries and microfeatures with tolerances down to a few microns, ensuring perfect alignment of punch and die components.

- Wire EDM (Electrical Discharge Machining): Enables precise cutting of hardened tool steels without inducing heat-affected zones, essential for maintaining die hardness and preventing warping.

- Die Surface Polishing and Coatings: Polished die surfaces reduce friction and prevent material adhesion, while PVD or CVD coatings (TiN, TiCN) enhance wear resistance and extend die life.

- Heat Treatment and Hardening: Gas nitriding or vacuum hardening processes increase surface hardness and fatigue strength, making metal stamping dies capable of sustaining millions of production cycles.

Combining these technologies ensures that every die component meets stringent quality criteria, delivering reliable performance and consistent stamping results even under demanding operational loads.

Automated Die Assembly and Inspection

To guarantee consistent quality and accelerate production readiness, Zhengqiang integrates automation into die assembly and verification:

- Robotic Fixture Assembly: Automated robots position and clamp die components with repeatable precision, reducing human error and assembly time.

- Laser Measurement Systems: High-resolution laser scanners perform non-contact dimensional checks, verifying die block flatness, punch alignment, and die clearance within sub-micron tolerances.

- Surface Roughness Profiling: Contact and optical profilometers assess surface finish to ensure friction coefficients and part release performance meet design specifications.

- Trial Runs on Robotic/Servo Presses: Simulated production runs validate die performance under actual stamping conditions, identifying required adjustments before full-scale deployment.

By combining robotics, precision metrology, and trial validation, Zhengqiang ensures that each set of metal stamping dies is production-ready, minimizing startup issues and safeguarding high-quality output from the first stroke.

Die Maintenance and Lifecycle Management

Preventive Maintenance Schedules

Effective upkeep of metal stamping dies is essential to prolong tool life and sustain part quality. Zhengqiang provides customized maintenance programs based on production data, including:

- Scheduled Lubrication Protocols: Applying specialized die lubricants to guides, bushings, and ejector systems to minimize wear and prevent galling.

- Comprehensive Cleaning Procedures: Ultrasonic cleaning and vapor degreasing to remove metal particle buildup, stamping oil residue, and debris that could impede die operation.

- Component Condition Monitoring: Periodic inspections of punch wear, die block integrity, spring tension, and alignment to identify signs of fatigue or misadjustment.

- Clearance Calibration: Measuring and adjusting die clearance based on production stroke counts to uphold clean cuts, minimize burrs, and maintain tolerance compliance.

These preventive measures mitigate unexpected breakdowns, reduce die refurbishment costs, and assure uninterrupted high-volume production with consistent part quality.

Die Refurbishment and Upgrades

Over time, metal stamping dies may exhibit wear or require adaptation to new part designs. Zhengqiang’s refurbishment services include:

- Regrinding and Sharpening: Restoring punch and die cutting edges to original profiles, improving shearing performance and surface finish.

- Bushing and Pin Replacement: Swapping worn guide components to restore precise alignment, stroke control, and mechanical stability.

- Retrofitting Additional Stations: Integrating new forming or trimming stages into existing die sets to accommodate design revisions or new part features.

- Material and Coating Upgrades: Replacing wear-prone components with advanced tool steels or applying next-generation coatings for enhanced durability.

By refurbishing dies to near-original specifications or upgrading them with improved materials and processes, Zhengqiang maximizes tool ROI while minimizing the capital expense of new tooling.

Applications of Metal Stamping Dies Across Industries

Automotive Sector

In the automotive industry, metal stamping dies are indispensable for producing body panels, chassis subframes, engine mounts, brackets, and heat shields. These dies enable:

- Consistent Panel Fit and Finish: Critical for door gaps, hood alignment, and aerodynamic performance.

- High-Strength Stampings: Utilizing advanced high-strength steels and lightweight alloys to enhance crashworthiness while reducing vehicle mass.

- Complex Under-hood Components: Fabricating heat shields and coolant system brackets with integrated flanges and embossed features in a single operation.

Zhengqiang collaborates with leading OEMs to develop progressive and transfer dies that meet rigorous automotive standards, ensuring safety, durability, and manufacturability.

Electronics and Electrical Components

Precision metal stamping dies produce miniaturized connectors, terminals, heat sinks, EMI shields, and battery contacts for consumer electronics and telecommunications equipment. Key benefits include:

- Fine-Pitch Features: Accurately stamping sub-millimeter features required for micro-USB, HDMI, and RF connector interfaces.

- High-Volume Compatibility: Enabling millions of stamping cycles for global electronics manufacturers with minimal die wear.

- Surface Quality and Plating Readiness: Producing burr-free parts that reduce post-stamping finishing steps and ensure plating adhesion.

Zhengqiang’s micro-stamping expertise supports the rapid evolution of 5G infrastructure and IoT ecosystems.

Appliance and Consumer Goods

For HVAC systems, washing machines, and small appliances, metal stamping dies create brackets, frames, functional hardware, and decorative trim. Advantages include:

- Robust Structural Parts: Consistent dimensional tolerances for seamless assembly and operation.

- Design Flexibility: Ability to integrate logos, vents, louvers, and mounting features into a single stamping sequence.

- Cost-Effective Production: High-volume runs that amortize tooling investment over millions of parts, reducing unit costs.

From refrigerator shelf supports to decorative trims, Zhengqiang’s dies power diverse consumer product manufacturing.

Aerospace and Defense

Stamping dies in aerospace applications demand extraordinary precision, material performance, and process validation. Typical stamped parts include:

- Structural Brackets and Airframe Assemblies: Fabricated from high-strength aluminum and titanium alloys for weight-critical components.

- EMI Shielding Plates: Ensuring electromagnetic compatibility in avionics systems.

- Precision Shims and Spacers: Manufactured to micron-level tolerances for turbine blade positioning and engine assembly.

Zhengqiang upholds stringent aerospace quality standards through detailed PPAP protocols, traceable material certifications, and full-process documentation.

Why Choose Zhengqiang Group?

- Over 20 years of expertise in precision die design and manufacturing

- Fully-integrated R&D, prototyping, production, and global after-sales support

- ISO 9001 and IATF 16949 certifications ensuring process consistency and traceability

- Flexible production capacities accommodating both small batches and mass production runs

- Dedicated technical team delivering customized stamping solutions and ongoing process optimization

Conclusion

Metal stamping dies remain the cornerstone of modern metal forming, offering unparalleled efficiency, precision, and cost-effectiveness across diverse manufacturing sectors. Zhengqiang Group’s end-to-end services—spanning feasibility analysis, advanced die design, precision manufacturing, automated assembly, preventive maintenance, and expert refurbishment—guarantee that every tool meets the highest benchmarks for performance, durability, and quality.

Ready to elevate your production with state-of-the-art metal stamping dies?

Contact Zhengqiang Group today for a detailed project evaluation, tailored tooling strategy, and free technical consultation—precision and efficiency, stamped to perfection.

FAQ

Q1: What materials can be processed with metal stamping dies?

A: Zhengqiang’s dies accommodate a wide range of metals, including cold-rolled and hot-rolled steel, stainless steel, aluminum alloys, copper, brass, nickel alloys, and other specialty alloys—each optimized for its specific forming characteristics and end-use requirements.

Q2: How do you determine die maintenance intervals?

A: Maintenance schedules are customized based on part complexity, material hardness, production volume, cycle counts, and in-die sensor feedback—ensuring timely lubrication, cleaning, inspection, and clearance adjustments.

Q3: What lead times should I expect for new die development?

A: Standard design-to-delivery for new metal stamping dies typically spans 6–8 weeks; expedited service options are available for urgent production demands, subject to tooling complexity.

Q4: Can you modify existing dies for new part designs?

A: Yes—Zhengqiang offers die refurbishment and retrofitting services that allow the integration of new features, additional stations, or material upgrades into existing die sets, minimizing downtime and capital expenditure.