- Information Classification

10 Powerful Metal Stamping Materials You Must Know for High-Performance Manufacturing

10 Powerful Metal Stamping Materials You Must Know for High-Performance Manufacturing

Introduction

Metal stamping materials play a decisive role in modern industrial manufacturing, directly influencing product durability, dimensional accuracy, and production efficiency. Selecting suitable metals for stamping is not only a cost decision but also a strategic choice that affects performance, compliance, and long-term reliability. From automotive components to consumer electronics and industrial enclosures, different metal forming materials are chosen based on strength, conductivity, corrosion resistance, and formability.

As a professional manufacturer, Zhengqiang Technology provides precision stamping solutions using a wide range of industrial metals to meet diverse global manufacturing needs.

👉 Learn more about our capabilities:

🔗 https://www.zqatech.com/

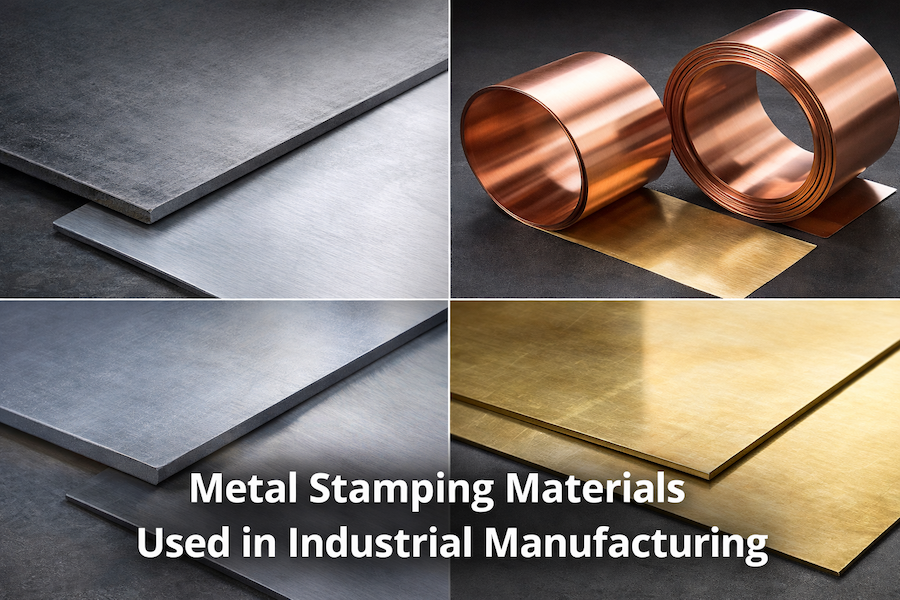

Common Metal Stamping Materials Used in Industrial Applications

Choosing the right stamping metal depends on mechanical requirements, operating environment, and production volume. Below are the most widely used metals in industrial stamping.

Steel Stamping Materials for Structural Strength

Steel remains one of the most common materials used in stamping due to its excellent strength, durability, and affordability. Low-carbon steel is easy to form, while high-carbon steel offers enhanced hardness for demanding applications.

Typical applications include:

-

Automotive brackets and frames

-

Industrial machine components

-

Structural enclosures

Steel stamping metals are ideal for high-volume production where consistency and load-bearing capacity are critical.

Stainless Steel Materials for Corrosion Resistance

Stainless steel is widely selected when corrosion resistance and aesthetic appearance are required. It provides excellent resistance to oxidation and chemical exposure, making it suitable for harsh environments.

Key advantages:

-

High corrosion resistance

-

Clean surface finish

-

Strong mechanical performance

These properties make stainless steel stamping materials ideal for medical devices, food equipment, and outdoor applications.

Aluminum Stamping Metals for Lightweight Design

Aluminum is one of the most popular lightweight metals used in stamping. It offers excellent formability, good corrosion resistance, and reduced overall product weight.

Common uses include:

-

Consumer electronics housings

-

Automotive lightweight parts

-

Heat dissipation components

Aluminum stamping metals are especially valuable in industries where energy efficiency and weight reduction are priorities.

Copper Stamping Materials for Electrical Performance

Copper is highly valued for its superior electrical and thermal conductivity. It is frequently used in precision stamping for electrical and electronic applications.

Advantages of copper stamping metals:

-

Excellent conductivity

-

High ductility

-

Stable performance

Copper materials are widely used in connectors, terminals, and electronic components.

Brass Materials Used in Decorative and Electrical Stamping

Brass, an alloy of copper and zinc, combines good conductivity with improved strength and corrosion resistance. It also offers an attractive surface finish.

Typical applications:

-

Electrical contacts

-

Decorative hardware

-

Precision fittings

Brass stamping materials are commonly used where both performance and appearance matter.

Galvanized Steel Materials for Outdoor Protection

Galvanized steel is coated with zinc to enhance corrosion resistance. This makes it suitable for outdoor and humid environments.

Key benefits include:

-

Long service life

-

Cost-effective protection

-

Strong structural performance

These materials are often used in construction, HVAC systems, and outdoor equipment housings.

Nickel Alloy Materials for High-Temperature Applications

Nickel-based alloys are used in stamping when high temperature resistance and chemical stability are required.

Applications include:

-

Aerospace components

-

High-temperature electrical parts

-

Specialized industrial equipment

Nickel alloys provide reliable performance under extreme conditions.

Choosing the Right Metal Stamping Materials for Your Project

When selecting metal forming materials, manufacturers should consider the following factors:

-

Mechanical strength requirements

-

Environmental exposure

-

Electrical or thermal conductivity

-

Production volume and cost targets

Working with an experienced stamping manufacturer ensures the optimal balance between performance and cost efficiency.

Why Choose Zhengqiang Technology for Precision Metal Stamping

At Zhengqiang Technology, we specialize in providing customized stamping solutions using high-quality metal stamping materials tailored to your application. Our advantages include:

-

Advanced tooling and precision molds

-

Strict quality control standards

-

Support for global OEM and ODM projects

-

Fast prototyping and mass production capabilities

Explore our full manufacturing services here:

🔗 https://www.zqatech.com/

FAQ: Metal Stamping Materials

What are the most commonly used metals in stamping?

Steel, stainless steel, aluminum, copper, and brass are among the most widely used stamping metals across industries.

How do I select the best stamping material?

Material selection depends on strength, corrosion resistance, conductivity, application environment, and budget.

Can Zhengqiang Technology customize stamping materials?

Yes. We offer material selection guidance and customized stamping solutions based on your technical requirements.

Conclusion

Selecting the right metal stamping materials is essential for achieving high performance, durability, and manufacturing efficiency. By understanding the properties of different stamping metals and working with an experienced supplier, manufacturers can optimize product quality while controlling costs.

📩 Contact Zhengqiang Technology today to discuss your next stamping project.