- Information Classification

What Is Magnetron in Microwave Oven | Zhengqiang Guide

Author | Zhengqiang Industry Insights Team

Updated | September 2025

Introduction: Understanding What Is Magnetron in Microwave Oven

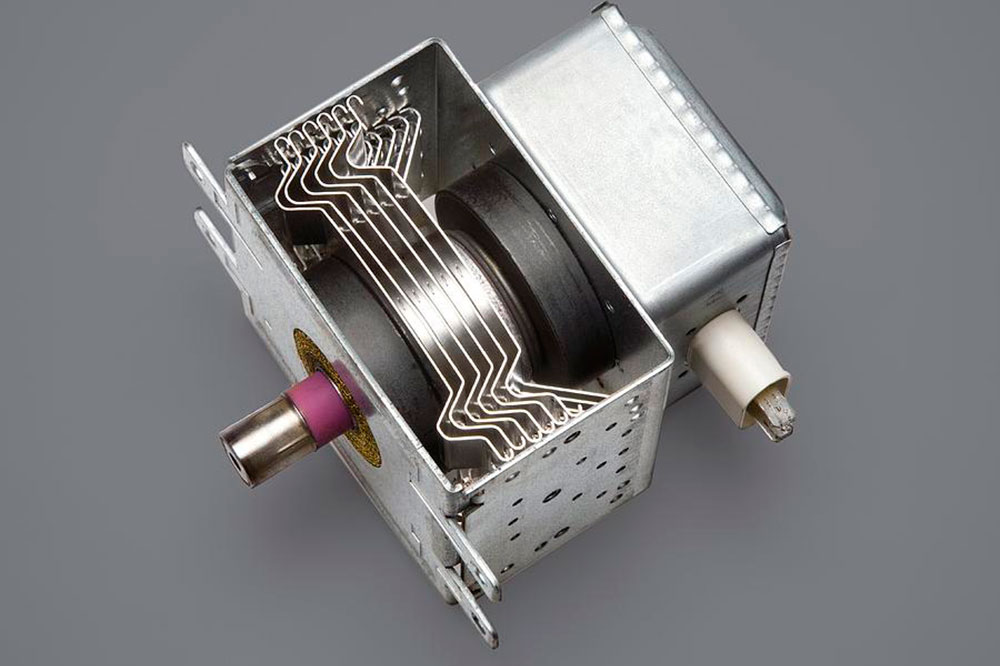

The magnetron is one of the most critical components in a microwave oven, and understanding what is magnetron in microwave oven is essential for manufacturers, engineers, and suppliers in the home appliance industry. As a core power amplifier used in microwave devices, the magnetron transforms electrical energy into microwave energy, which allows food to heat rapidly and efficiently.

Modern households increasingly rely on microwave ovens for convenience, speed, and energy efficiency, making the quality of the magnetron vital for product reliability. For top microwave oven brands, magnetrons are a key differentiator, influencing cooking speed, uniformity, and appliance longevity. This guide will provide a detailed explanation of the magnetron’s structure, working principles, manufacturing considerations, and industrial applications, helping manufacturers understand how to optimize their products.

What Is Magnetron in Microwave Oven? Core Definition

A magnetron in microwave oven is a thermionic vacuum tube, also known as a “hot cathode tube,” designed to generate high-frequency microwave energy through the interaction of electrons and a magnetic field. Unlike conventional electrical heating elements, which rely on direct resistance, the magnetron converts electrical energy into electromagnetic waves that penetrate food, heating it from the inside out.

Understanding what is magnetron in microwave oven is crucial for manufacturers because the magnetron’s efficiency determines the oven’s performance, energy consumption, and lifespan. High-quality magnetrons produce stable microwave energy, prevent hotspots, and ensure consistent cooking results. Furthermore, their design and material selection directly impact durability, with high-grade metals and precise machining ensuring stable output under long-term operation, making it a critical component for OEMs and appliance brands worldwide.

How Does Magnetron Work in Microwave Oven?

To fully grasp what is magnetron in microwave oven, it is necessary to understand its working principle. The magnetron primarily consists of the cathode (electron gun) and resonant cavities (microwave resonators), complemented by a magnetic field to guide electron motion. The process begins with the cathode emitting electrons, which are then accelerated by a high-voltage field toward the anode. Under the influence of the perpendicular magnetic field, these electrons follow spiral paths, interacting with the resonant cavities and transferring their kinetic energy into microwave radiation.

This microwave energy is then directed through a waveguide into the oven cavity, where it penetrates food, rapidly exciting water molecules to produce heat. The ability to convert electrical energy efficiently into microwave energy makes the magnetron the heart of microwave heating. Engineers designing microwave ovens must understand these principles to ensure optimal energy efficiency, safety, and consistent cooking results.

Components of Magnetron in Microwave Oven

Knowing what is magnetron in microwave oven requires familiarity with its critical components, each of which contributes to performance and durability.

-

Cathode (Hot Electron Gun): Responsible for emitting electrons when heated. High-quality cathodes use materials resistant to wear and oxidation, ensuring long-term performance.

-

Anode Block and Resonant Cavities: Shape the electron flow and convert kinetic energy into microwaves. Precision machining ensures correct resonance frequency for stable microwave generation.

-

Magnets: Generate the perpendicular magnetic field that guides electrons in spiral paths. Proper alignment is crucial to maximize energy conversion efficiency.

-

Cooling System: Many magnetrons include fins or heat sinks to dissipate excess heat, preventing degradation of internal components.

-

Output Antenna: Transmits microwave energy from the resonant cavities to the waveguide for even distribution in the oven.

Each component must be manufactured with tight tolerances, as minor deviations can lead to decreased efficiency, reduced lifespan, or inconsistent microwave output. Manufacturers must pay careful attention to material selection, precision machining, and assembly quality to ensure optimal performance of the magnetron.

Role of Magnetron in Microwave Oven Performance

The magnetron is the core element that determines how well a microwave oven performs, which highlights why understanding what is magnetron in microwave oven is critical for manufacturers. Its primary role is to generate high-frequency microwave energy rapidly, allowing food to heat uniformly and efficiently. A well-engineered magnetron ensures that microwaves are distributed evenly across the oven cavity, preventing cold spots and overcooked areas.

Additionally, high-quality magnetrons reduce energy consumption by converting electricity into microwave energy with minimal losses. This not only improves appliance efficiency but also supports compliance with energy standards. Consistent microwave output also extends the lifespan of the oven, prevents electronic component failures, and enhances customer satisfaction. By prioritizing magnetron quality, manufacturers can achieve a competitive advantage in terms of both product reliability and brand reputation.

Quality Considerations for Magnetron Manufacturing

Understanding what is magnetron in microwave oven extends to quality considerations that are crucial for OEMs and suppliers. High-quality magnetrons depend on precision engineering, rigorous material selection, and careful assembly. For instance, cathodes must resist oxidation and maintain consistent electron emission under high temperatures, while resonant cavities must be accurately machined to produce the correct microwave frequency. Magnet alignment must be precise to guide electron paths efficiently, and the cooling system must prevent overheating during continuous operation.

Manufacturers must also implement comprehensive testing, including microwave output validation, life-cycle testing, and electrical safety checks. By adhering to strict quality standards, manufacturers ensure that magnetrons perform reliably in demanding environments, meet international safety certifications, and satisfy OEM expectations for durability, performance, and energy efficiency.

Applications of Magnetron Beyond Household Microwaves

While the primary application of a magnetron is in household microwave ovens, understanding what is magnetron in microwave oven also helps explore broader industrial applications. Magnetrons are widely used in commercial kitchens for high-capacity ovens, conveyor systems, and rapid reheating solutions. In the medical field, magnetrons are employed in microwave-based sterilization equipment, ensuring efficient and hygienic operation.

Industrial heating processes also benefit from magnetron technology, particularly for dielectric heating of materials requiring precise, rapid energy transfer. Additionally, research and laboratory equipment use magnetrons to generate controlled microwave energy for experiments and testing. The compact design, high efficiency, and reliability of magnetrons make them versatile across multiple sectors, further emphasizing the importance of sourcing quality components for consistent performance.

Why Choose Zhengqiang for Magnetron Manufacturing

Zhengqiang Technology Group has decades of experience providing high-quality magnetrons for leading microwave oven brands. Manufacturers who choose Zhengqiang benefit from:

-

Advanced plating and surface treatment, ensuring corrosion resistance and long-term durability.

-

Precision machining and assembly for stable microwave output and consistent performance.

-

Rigorous quality control, including electrical testing and life-cycle validation.

-

Scalable production capabilities to meet the demands of OEMs worldwide.

-

Compliance with international safety and efficiency standards.

Partnering with Zhengqiang ensures that each magnetron meets strict specifications, delivering superior reliability, energy efficiency, and customer satisfaction. Our team of engineers provides tailored solutions to optimize the performance of your appliances.

Conclusion: Magnetron as the Heart of Microwave Oven

Understanding what is magnetron in microwave oven is essential for manufacturers who aim to produce reliable, high-performance microwave ovens. Its precise design, efficient energy conversion, and durable construction make it indispensable for rapid and even food heating. Selecting high-quality magnetrons improves product reliability, customer satisfaction, and brand reputation.

Contact Zhengqiang Technology Group today to source premium magnetrons for your microwave ovens, customize specifications, or consult with our engineering team. Let us help you deliver excellence and performance in every appliance.

FAQs

Q1: How long does a typical magnetron last in a microwave oven?

With high-quality design and materials, magnetrons can last 5–10 years under normal household usage. Life span may vary depending on usage frequency, power settings, and operating conditions.

Q2: Can magnetrons be repaired?

Due to high voltage and intricate internal structure, magnetrons are generally replaced rather than repaired to ensure safety and performance.

Q3: Are all magnetrons in microwaves the same?

No, magnetrons vary by power output, size, and frequency, depending on the oven type and brand specifications. Industrial ovens often use higher power magnetrons compared to household models.

Q4: How do I ensure high-quality magnetrons for manufacturing?

Partner with trusted suppliers like Zhengqiang, who offer rigorous quality control, testing, and compliance with international safety standards.

Q5: How does magnetron quality affect oven performance?

A high-quality magnetron ensures even heating, energy efficiency, longer appliance lifespan, and greater customer satisfaction.