Precision Parts Manufacturers | Custom Tooling Solutions

Precision Parts Manufacturing & Mold Customization Solutions

Zhengqiang Group provides end-to-end precision manufacturing solutions backed by over 100 senior engineers, offering comprehensive services from design and prototyping to mass production. We specialize in precision stamping (progressive/transfer dies), advanced surface treatments (plating/coating/heat treatment), and custom material fabrication (stainless steel/aluminum/iron). Our engineering expertise ensures superior quality through DFM optimization, precision tooling design, and continuous process improvement, delivering reliable solutions from prototype development to high-volume production with strict quality control at every stage.

R&D and engineering support

Zhengqiang Group provides end-to-end precision manufacturing solutions backed by over 100 senior engineers, offering comprehensive services from design and prototyping to mass production. We specialize in precision stamping (progressive/transfer dies), advanced surface treatments (plating/coating/heat treatment), and custom material fabrication (stainless steel/aluminum/iron). Our engineering expertise ensures superior quality through DFM optimization, precision tooling design, and continuous process improvement, delivering reliable solutions from prototype development to high-volume production with strict quality control at every stage.

Large-scale production and supply chain management

Zhengqiang Group is a leading precision manufacturing partner with proven annual production capacity of 24 million motors, 1 billion precision metal components, and 500 million industrial ceramic parts. Our modern workshops and automated equipment enable large-scale production with stringent quality control, while the intelligent MES system ensures real-time monitoring for enhanced efficiency and cost optimization. By integrating global supply chain resources, we streamline procurement, logistics and inventory management to deliver cost-effective manufacturing solutions with reliable on-time delivery from prototyping to high-volume production.

Quality control system

Full-process quality control to ensure excellent product quality

We strictly implement ISO9001, IATF16949 and other quality management systems, and

set strict quality standards for each link from raw material procurement to production and

manufacturing to finished product testing. Zhengqiang is equipped with advanced testing

equipment, such as three-coordinate measuring machine (CMM), spectrometer, X-ray

detector, etc., to ensure that each product achieves high precision and high stability. In

addition, we also support customers to provide third-party certification services to meet the

regulatory requirements of specific industries.

Global logistics and after sales support

Efficient And Rigorous Manufacturing Process To Ensure Quality And Delivery

Zhengqiang follows a scientific and rigorous manufacturing process.

From demand communication to delivery acceptance, each step is strictly controlled to ensure stable product quality, high production efficiency, and on-time delivery. Provide customers with efficient and reliable manufacturing solutions.

1. Demand communication and project evaluation

We communicate deeply with customers to understand product functions, application scenarios and quality requirements, and evaluate material selection, process solutions and production feasibility. Through DFM (manufacturability analysis), we optimize the design solution to ensure that the product meets customer needs and can be produced efficiently.

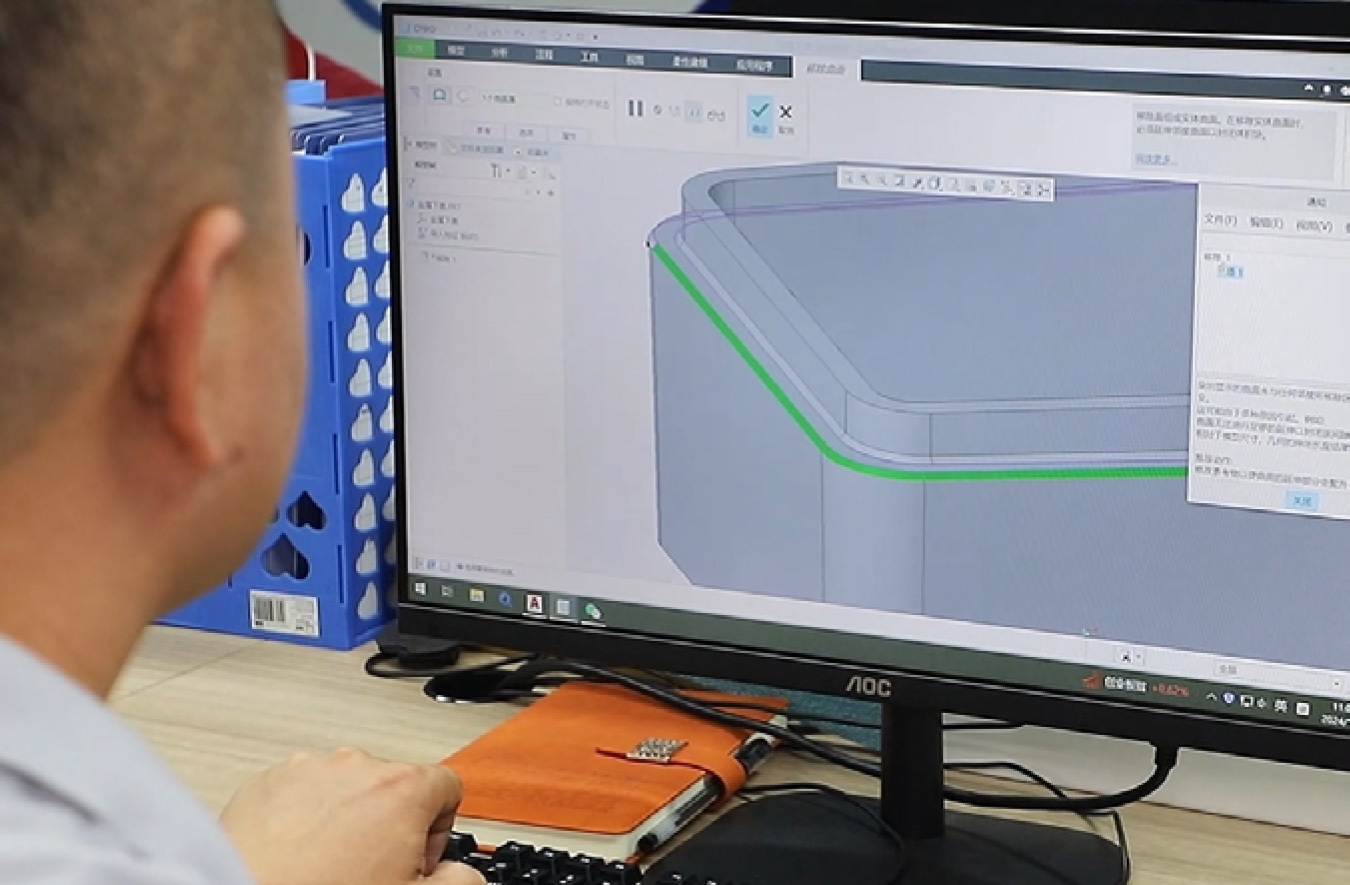

2. R&D design and engineering support

Technical experts help to optimize product design and process Our engineering team provides technical support such as 3D modeling, product structure optimization, and mold design to ensure product accuracy, strength and manufacturability. At the same time, we use CAE simulation analysis and rapid prototyping verification to discover and optimize potential problems in advance and shorten the development cycle.

3. Trial production and sample testing

Quick proofing to ensure the feasibility of the design solution Before mass production, we conduct small-batch trial production to verify process parameters, processing accuracy and product performance. All samples will undergo strict testing, including dimensional measurement, material performance testing, functional testing, etc., to ensure that they meet customer quality standards.

4. Large-scale production and quality control

Intelligent production ensures stable and efficient delivery During the mass production stage, we use automated equipment and precision processing technology to improve production efficiency and ensure consistency. The quality management system runs through the entire production process, and key processes are all tested online to ensure that products are stably mass-produced under high standards.

5. Full-process quality inspection

Strict quality inspection system to ensure that products meet industry standards All products undergo multiple tests, including CMM three-coordinate measurement, optical inspection, non-destructive testing, durability testing, etc. For high-demand industries such as medical devices and automotive parts, we provide industry certification support to ensure that products meet international standards.

6. Delivery and after-sales support

On-time delivery and full-range technical support Zhengqiang cooperates with global logistics partners to provide flexible transportation solutions to ensure that products are delivered on time and safely. At the same time, we provide after-sales technical support, including remote guidance, product maintenance and quality tracking to ensure that customers use it without worries.

COOPERATE PARTNERS

Zhengqiang Provides Global Customers With The Latest And Most Comprehensive Precision Component Solutions With Professional Technology And Efficient Cost-Effectiveness, Helping Global Partners Achieve Success.

Industry Applications

Zhengqiang is deeply engaged in the field of precision manufacturing. With advanced process technology and strict quality management, it widely serves multiple industries, including home appliances, consumer electronics, high-end kitchen appliances, new energy vehicles, medical instruments, industrial automation, etc. We provide customers with customized solutions to ensure that the products meet industry standards in terms of performance, precision and durability.

Home Appliances

As trusted precision parts manufacturers, we provide high-performance components for motors, stamped parts, and capacitors used in home appliances, ensuring durability and energy efficiency in every household device.

Electronic components

We support electronic component innovation with customized precision parts. As experienced precision parts manufacturers, we deliver reliable micro parts and advanced materials for stable and scalable electronics production.

Automobile manufacturing

From precision stamping to surface-treated metal parts, we serve the evolving needs of the automotive sector. As precision parts manufacturers, we meet strict automotive standards for performance, reliability, and cost efficiency.

Photovoltaic energy storage

We empower solar and energy storage manufacturers with custom-engineered metal and ceramic parts. As precision parts manufacturers, we ensure thermal stability and long-term reliability for clean energy applications.

Healthcare & Medical Devices

Medical devices demand uncompromising accuracy. As precision parts manufacturers, we produce complex and miniaturized components that meet rigorous hygiene, safety, and regulatory standards for healthcare applications.

Communication equipment

We enable stable signal performance with precision connectors and structural components. As dedicated precision parts manufacturers, we serve the telecom and 5G infrastructure sectors with highly customized solutions.

Get a Free Consultation Now

Looking for reliable, custom-engineered components for your next project? As trusted precision parts manufacturers, Zhengqiang Technology delivers end-to-end solutions with unmatched quality and speed. Contact us now to discuss your specific needs — let’s build your competitive edge together.