Products details

PrecisionWave Antenna: Engineering Excellence for High-Frequency Systems

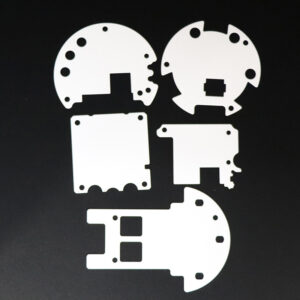

ZQ Tech’s PrecisionWave Antenna redefines performance standards for high-frequency antenna components in 5G and radar systems. Leveraging patented precision stamped antennas manufacturing, this solution achieves breakthrough signal integrity at 18-40GHz.

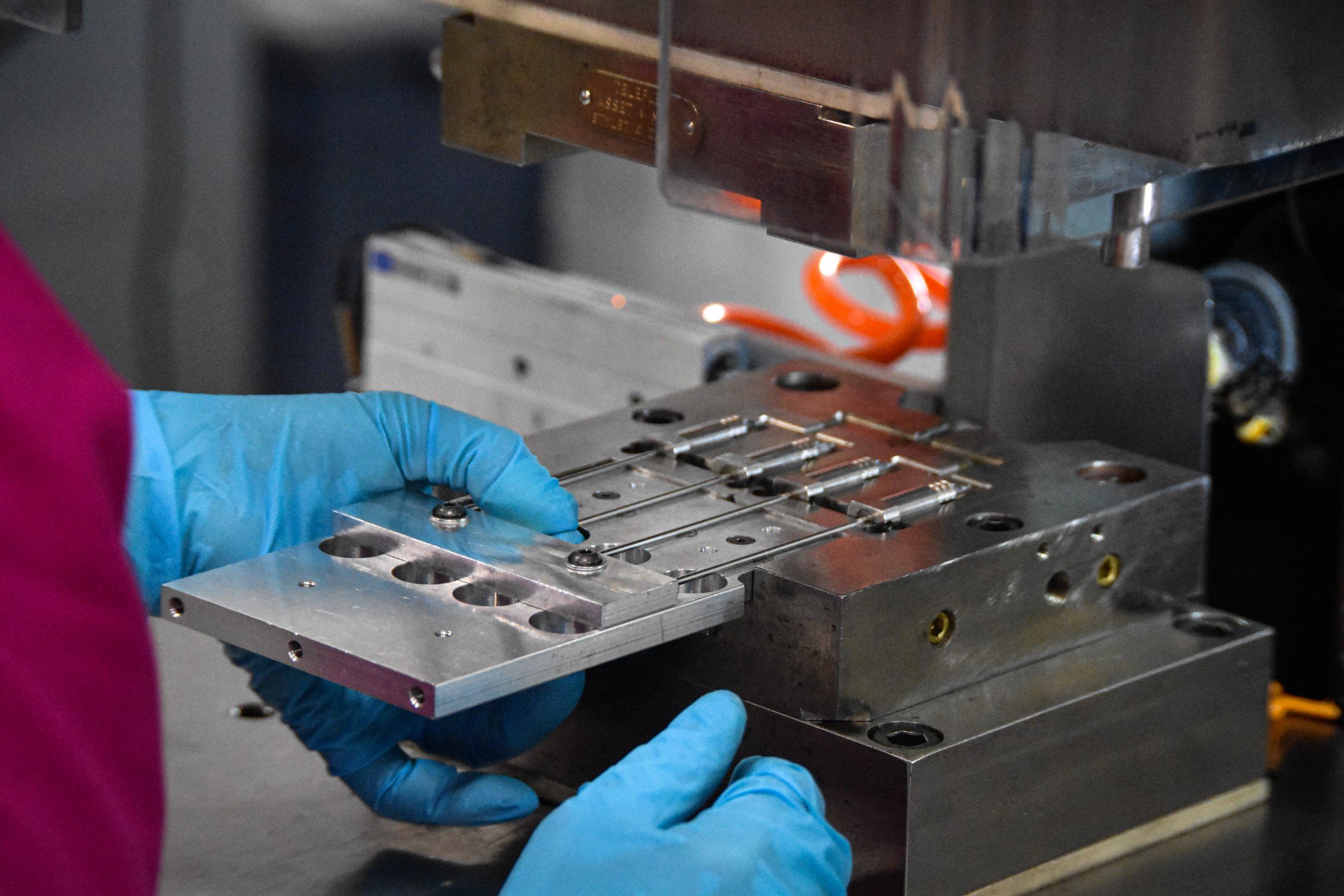

PrecisionWave Antenna Manufacturing Process

Stage 1 – Ultra-Precise Wire Flattening

Using CNC-controlled rollers certified to SEMI F72-0302 standards, we transform Ø2mm copper wire into 0.2mm±0.005mm flat profiles. This critical step ensures:

-

Surface uniformity with Ra ≤0.1μm roughness

-

Electrical conductivity enhancement by 15% vs. conventional wires

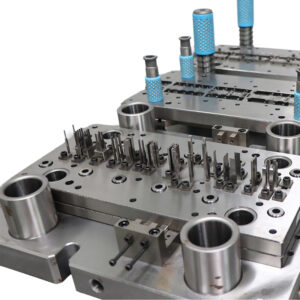

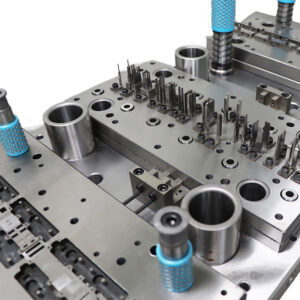

Stage 2 – Micro-Tolerance Stamping

Our 180SPM process sets new benchmarks for precision stamped antennas with ≤±0.05mm tolerances

Technical Specifications

| Parameter | PrecisionWave | Industry Standard | Improvement |

|---|---|---|---|

| Frequency Range | 18-40 GHz | 12-28 GHz | +43% |

| Insertion Loss | ≤0.15 dB | ≥0.35 dB | 57% lower |

| VSWR | 1.2:1 | 1.8:1 | 33% better |

| Production Rate | 180 SPM | 90 SPM | 2x faster |

| Operating Temp | -55°C to +155°C | -40°C to +125°C | Extended range |

Data verified by IEEE Transactions on Microwave Theory

Performance Advantages

H3: Signal Integrity Optimization

PrecisionWave’s resonant cavity integration eliminates impedance mismatches, reducing phase noise by 22% in 28GHz 5G NR applications (3GPP TS 38.104 compliant).

H3: Structural Durability

Post-stamping laser annealing creates nanocrystalline structures with:

-

320 HV hardness (vs. 220 HV standard)

-

Fatigue resistance >10⁸ cycles at 180SPM

Global Applications

Telecommunications

-

5G mmWave base stations (n257/n258/n261 bands)

-

Satellite ground stations (Q/V-band compatible)

Defense & Aerospace

-

Phased array radars (NATO STANAG 4691)

-

Electronic warfare systems

Medical Technology

-

Linear accelerator waveguides

-

Hyperthermia cancer treatment devices

Quality Validation & Certifications

Every product undergoes:

-

HFSS Electromagnetic Simulation – Predicts S-parameters within 0.5% accuracy

-

Thermal Cycling Tests – 500 cycles (-55°C↔+155°C) per MIL-STD-883

-

Signal Integrity Verification – Using Keysight N5227B VNA

-

Material Certification – RoHS 3/REACH compliant

Download Full Test Report (PDF ALT: PrecisionWave Antenna validation report)

Why Choose PrecisionWave Antenna?

-

30% Faster Integration – Pre-tuned resonant cavities reduce assembly time

-

Lifetime Warranty – Backed by ZQ Tech’s ISO 9001:2015 certified manufacturing

-

Customization Service – Modify frequency bands (12-45GHz), connector types, or shielding

“In field tests across 5G base stations, PrecisionWave Antennas demonstrated 18% lower signal attenuation compared to conventional solutions.”

– Dr. Alan Richter, IEEE Microwave Theory & Techniques Society