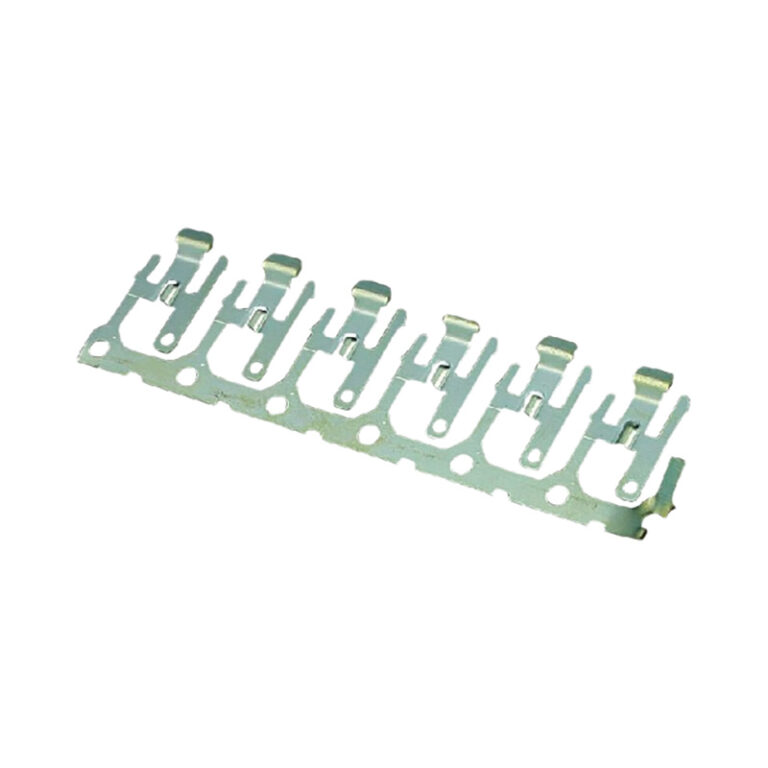

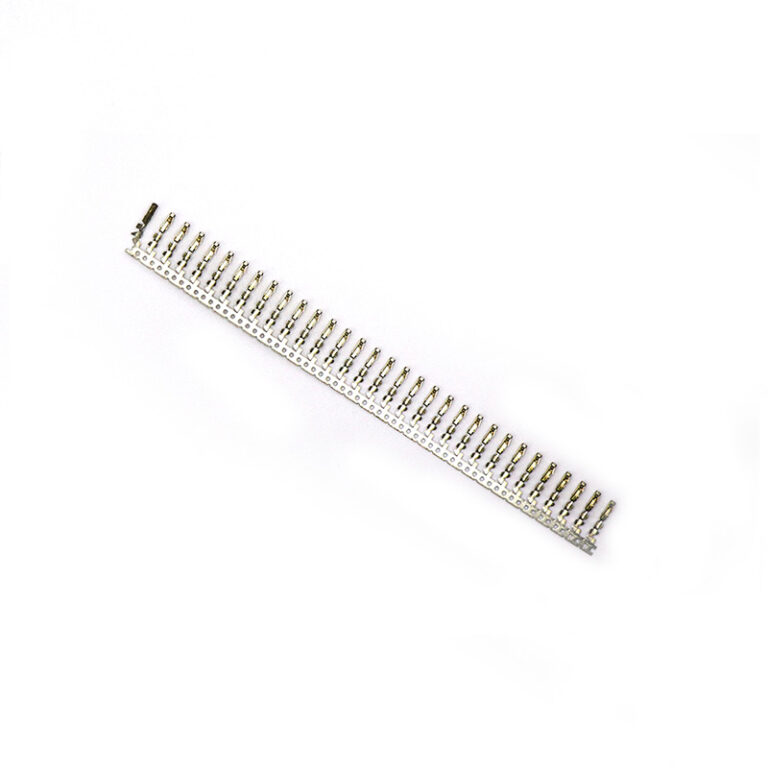

Precision Stamped Terminals Contacts hardware

1.Precision Stamped Terminals, High Conductivity, Stable Signal Transmission

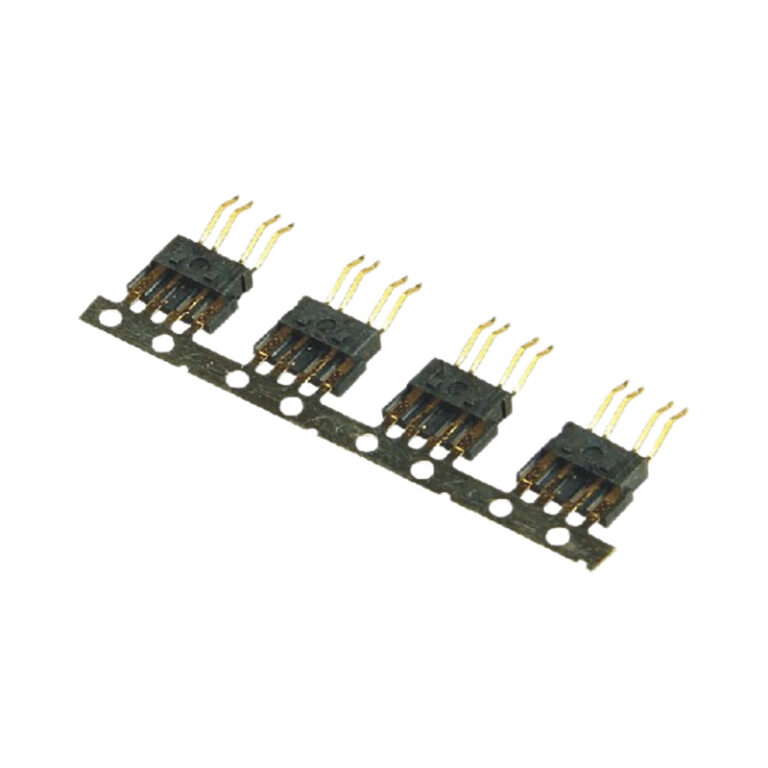

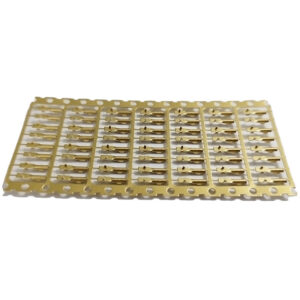

2.Gold/Tin-Plated Terminals, Anti-Oxidation, Extended Service Life

3.Plug-and-Play Terminals, Easy Installation, Saves Wiring Time

4.Barrier Terminals, Secure Connections, Suitable for High-Current Applications

5. Spring-Loaded Terminals, Tool-Free Installation, Easy Maintenance

6. DIN Rail Terminals, Space-Saving, Enables Centralized Management

7.Waterproof and Dustproof Terminals, Safe and Reliable for Outdoor Use

8.High-Temperature Resistant Terminals, Stable Performance in High-Temperature Environments

9.Customized Terminals, Tailored to Meet Individual Needs

10.Cost-Effective Terminals, Quality Assurance, Competitive Pricing

Application :

Industrial Control/Automotive Electronics/Household Appliances/Communication Equipment/New Energy/Rail Transportation/Medical Equipment/Aerospace

Our Advantages:

1. Trusted Partnerships: Long-term collaborations with global leaders like Fulin Precision, Amphenol, and Bosch.

2. Scale & Quality: Advanced equipment and over 10 automated production lines ensures consistent, high-quality output for large-scale demands.

3. Custom Solutions: Expert team delivers tailored solutions for diverse applications.

4. Reliable Delivery: Efficient supply chain guarantees on-time delivery and support.

5. Innovation Driven: Continuous R&D keeps us ahead in competitive solutions.

2.Gold/Tin-Plated Terminals, Anti-Oxidation, Extended Service Life

3.Plug-and-Play Terminals, Easy Installation, Saves Wiring Time

4.Barrier Terminals, Secure Connections, Suitable for High-Current Applications

5. Spring-Loaded Terminals, Tool-Free Installation, Easy Maintenance

6. DIN Rail Terminals, Space-Saving, Enables Centralized Management

7.Waterproof and Dustproof Terminals, Safe and Reliable for Outdoor Use

8.High-Temperature Resistant Terminals, Stable Performance in High-Temperature Environments

9.Customized Terminals, Tailored to Meet Individual Needs

10.Cost-Effective Terminals, Quality Assurance, Competitive Pricing

Application :

Industrial Control/Automotive Electronics/Household Appliances/Communication Equipment/New Energy/Rail Transportation/Medical Equipment/Aerospace

Our Advantages:

1. Trusted Partnerships: Long-term collaborations with global leaders like Fulin Precision, Amphenol, and Bosch.

2. Scale & Quality: Advanced equipment and over 10 automated production lines ensures consistent, high-quality output for large-scale demands.

3. Custom Solutions: Expert team delivers tailored solutions for diverse applications.

4. Reliable Delivery: Efficient supply chain guarantees on-time delivery and support.

5. Innovation Driven: Continuous R&D keeps us ahead in competitive solutions.

Products details

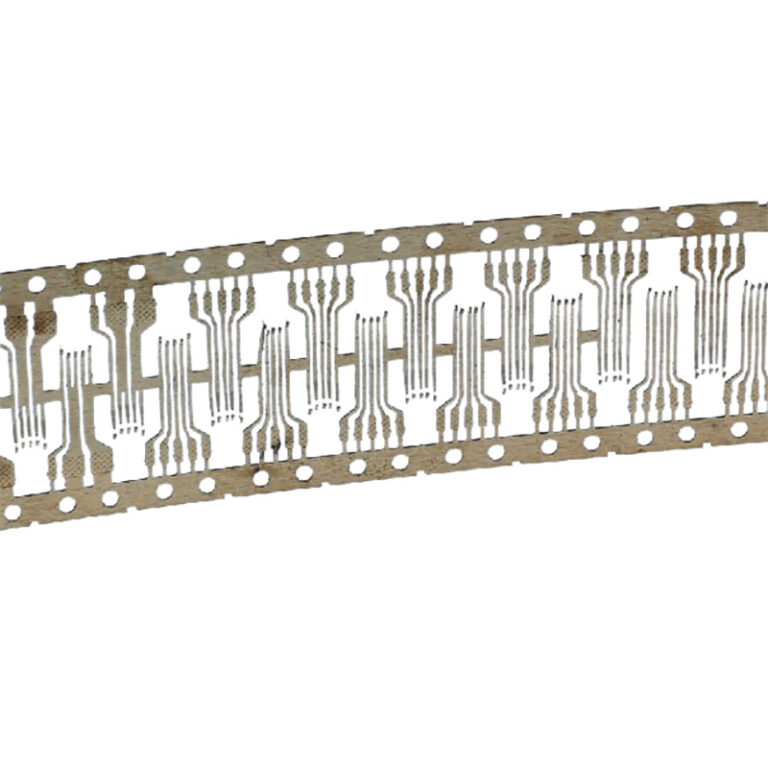

Stamped Terminals Contacts Technology

Engineered for Demanding Automotive Applications

Superior Corrosion Protection

-

Zinc-nickel & DLC coatings withstand 1000+ salt spray hours

-

Stainless steel variants for extreme environments

Precision Performance

✔ ±0.01mm tolerances for perfect fit

✔ IATF 16949 certified production

✔ Tested to SAE/USCAR standards

Precision Stamped Terminals Contacts

Trusted by Automotive Leaders OEM-Approved Quality

-

Direct supplier to FAW-Volkswagen, BYD, Yamaha

-

Zero-defect PPM <50 in mass production

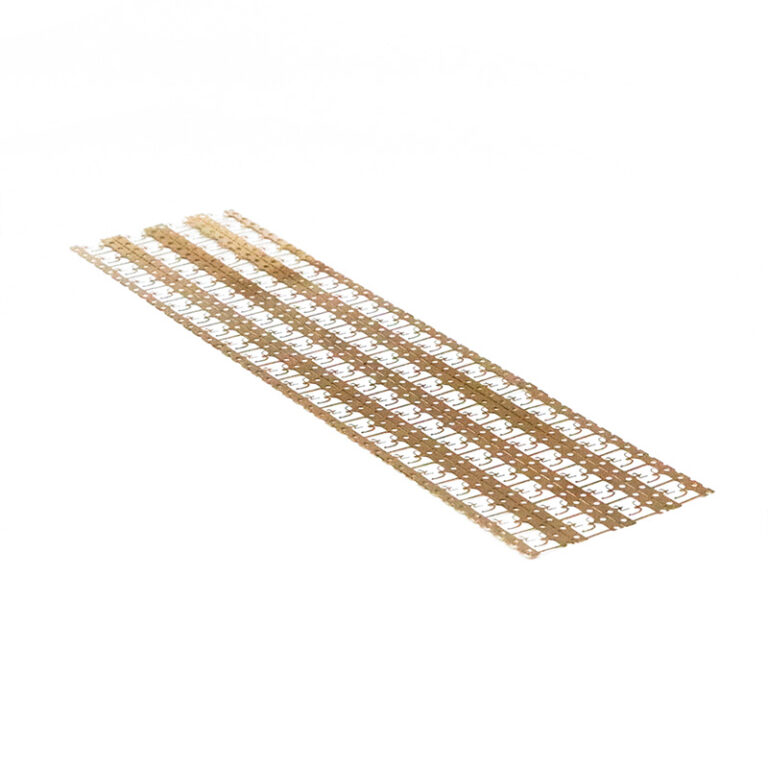

NEV-Focused Solutions

-

Charging gun pins with <1mΩ resistance

-

EMI shielding components

Advanced Manufacturing Capabilities

High-Volume Production

-

50M+ annual capacity

-

Automated CNC machining

Customization Services

-

Material selection (stainless/copper alloys)

-

Coatings optimized for application