Core Technology & Functionality

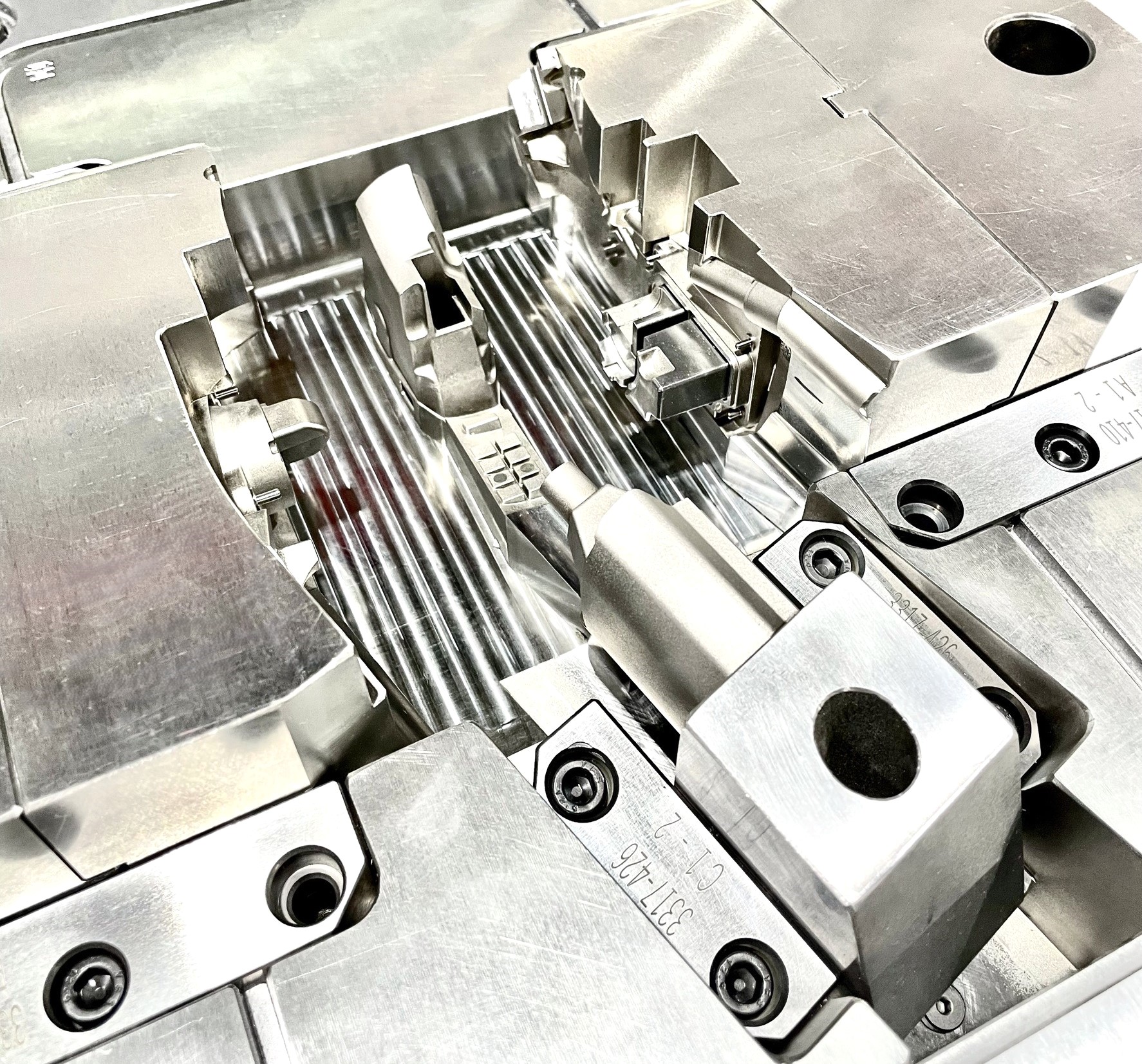

Our large stator stacks leverage proprietary multi-layer stamping technology on custom-built presses, enabling simultaneous production of stators, rotors, and brackets in a single cycle. Key innovations:

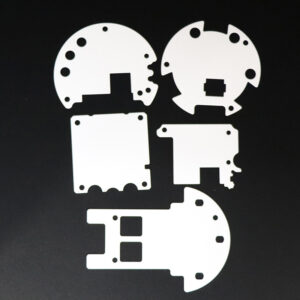

Precision Layering: Achieves ≤0.05mm lamination alignment for minimized eddy current losses.

Custom Geometry: Tailored slot patterns/pole counts (e.g., 16-pole configurations) to match client specifications.

Integrated Tooling: Dedicated dies co-produce small/large stators and rotors, reducing material waste by 18%.

Core Role:

Optimizes magnetic flux efficiency in motors, boosting torque density by 15% while reducing iron losses.

Products details

Precision-Laminated Stator Stack for Energy-Efficient Motors

Our laminated stator stack is manufactured using multi-layer progressive stamping on industry-exclusive synchronized presses. Each cycle produces stators, rotors, and brackets with sub-0.05mm alignment, ensuring reduced eddy current loss and optimized magnetic coupling.

Custom Geometry in Laminated Motor Cores

UniPress supports a wide range of customizations—from pole counts like 16-pole setups to unique stator slot geometries. These modifications help OEMs align the electromagnetic profile of each motor core to their specific application needs. Dedicated dies allow for integrated forming, reducing material waste by up to 18%.

High-Efficiency Performance & Manufacturing Scalability

Each stator stack is precision-aligned to boost torque density by 15% and reduce iron losses significantly. Our ISO 9001-certified production lines offer ±0.01mm accuracy. High-volume output exceeding 200,000 units/day is achieved through full automation, including optical sorting and inline inspection.

Applications

-

Home Appliances: Compressors, HVAC motors, and fan drives.

-

EV Components: Inverters, traction motors (future-ready).

-

Industrial Automation: Precision gear motors and servo drive cores.

Why Choose Us

Exclusive Production Capability:

Industry-only custom press for synchronized stator-rotor-bracket output.

Precision Engineering:

±0.01mm stamping accuracy (validated via ISO 9001-certified QC).

Cost Efficiency:

Shared tooling slashes unit costs by 20% vs. traditional methods.

Rapid Customization:

45-day lead time from design to mass production (including mold development).

High-Volume Output:

200,000+ units/day capacity with automated optical sorting.

Learn more about laminated motor core technology via this technical overview from IEEE