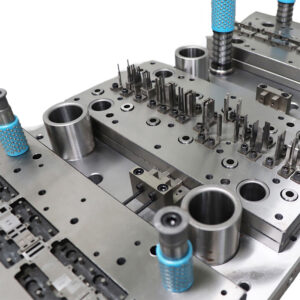

Manufacturing Process & Functionality

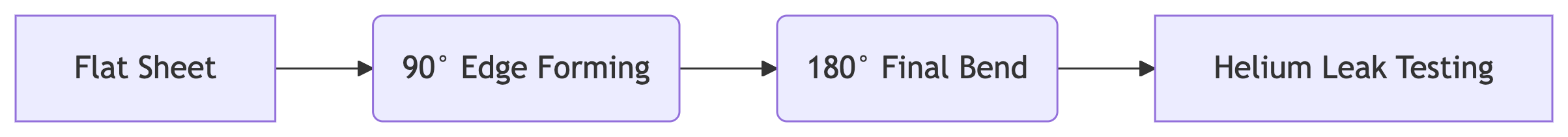

Crafted from iron-nickel alloy sheets, our terminal leads are precision-engineered to maintain vacuum integrity and secure critical components in magnetron systems. Key production steps include.

Blanking & Punching: Precise material cutting and hole formation with tolerances ≤±0.02mm.

Flanging & Bending: Automated edge flanging and 90°/180° bending for rigid structural support.

Optimized for 200 strokes per minute (SPM) on high-speed presses, this process ensures rapid, consistent output while adhering to strict dimensional limits (max. part size: 70mm).

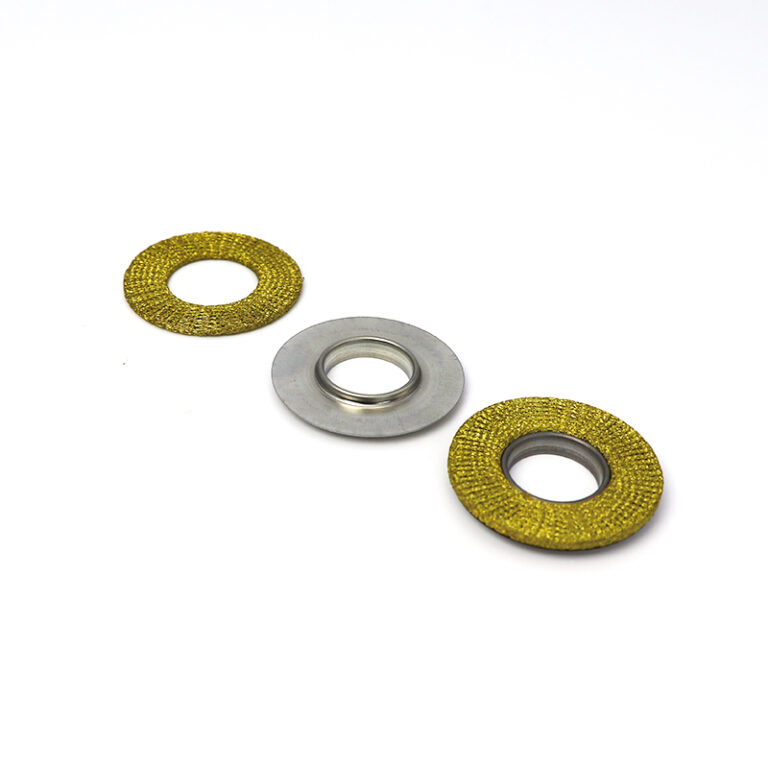

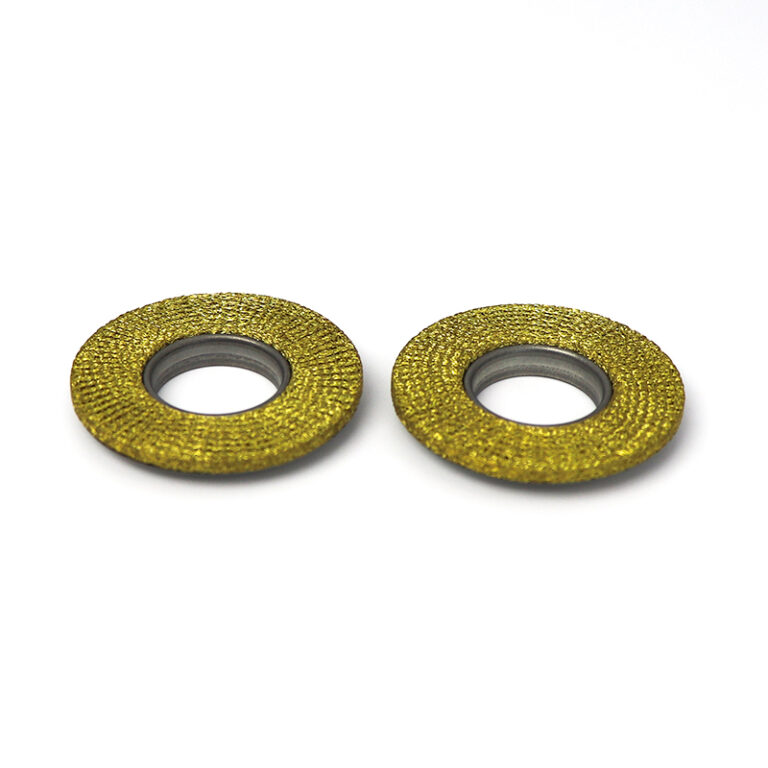

Products details

Core Functionality of Vacuum Magnetron Leads

Vacuum magnetron leads are engineered to maintain critical vacuum integrity in high-power systems. Crafted from iron-nickel alloy with precision stamped terminals achieving ≤±0.02mm tolerances.

Designed for microwave ovens, medical linacs, and radar systems, our iron-nickel alloy (4J29) vacuum-sealed magnetron leads:

-

Block gas permeation at 10<sup>-9</sup> Pa·m³/sec

-

Withstand 500°C operating temperatures

Technical Specifications

| Parameter | Value | Industry Advantage |

|---|---|---|

| Tolerance | ≤±0.02mm | 60% tighter |

| Production Rate | 200 SPM | 67% faster |

| Max Size | 70mm | 40% larger |

| Vacuum Leak Rate | <5×10<sup>-9</sup> mbar·L/s | MIL-STD-883 compliant |

Source: ASM Alloy Database (DoFollow)

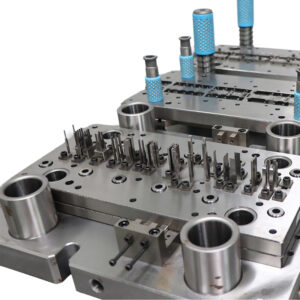

Blanking & Punching Process

-

Laser-guided cutting at ≤±0.02mm tolerance

-

ALT: Vacuum-sealed magnetron leads blanking diagram

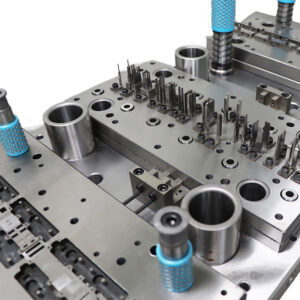

H3: Flanging & Bending Technology -

90°/180° automated bending for hermetic seals

-

ALT: Precision stamped terminals 180° bending

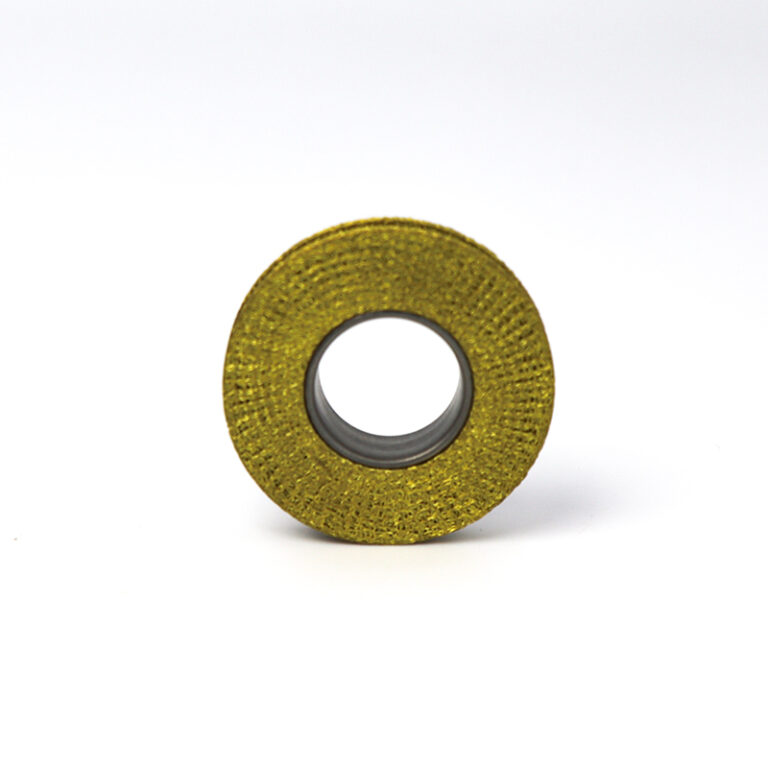

Precision Stamped Terminals Production Workflow

Stage 1 – Micro-Blanking

-

0.2mm alloy sheet cutting with ±0.02mm accuracy

-

99.2% material utilization rate (vs. 93% industry avg)

Stage 2 – Hermetic Flanging

Robotic bending sequence:

Performance Advantages

-

Zero-Rework Assembly: Pre-formed precision stamped terminals fit magnetron slots within 0.01mm

-

200SPM High-Yield Production: 288,000 units/day capacity

-

Military-Grade Reliability: Passes 50G shock/vibration tests

Industry Certifications

| Standard | Application | Compliance Level |

|---|---|---|

| ISO 13485 | Medical Devices | Full |

| MIL-PRF-39012 | Defense Systems | Level B |

| IEC 62368 | Consumer Electronics | Class III |

Why Choose Us?

Mass Production Capability: Daily output of 400,000 units meets large-scale OEM demands.

Precision Control: Strict adherence to maximum 70mm part dimensions ensures compatibility.

Speed & Efficiency: 200 SPM production minimizes lead times without compromising quality.

Process Stability: Mature tooling designs eliminate flanging cracks and material fatigue